How to Integrate Pallet Inverters into Your Warehouse Management System?

Imagine this: a critical shipment is delayed because a heavy coil is stuck on a damaged pallet. Workers scramble, using risky manual methods to transfer the load. Production lines slow down, and safety alarms ring in your head. This is the daily reality in many warehouses and factories that handle heavy goods like steel coils or wire rods. The bottleneck isn't just the packing; it's the entire material flow system. The core issue often lies in the inefficient handoff between storage, production, and shipping—a gap that a well-integrated pallet inverter system is uniquely designed to bridge.

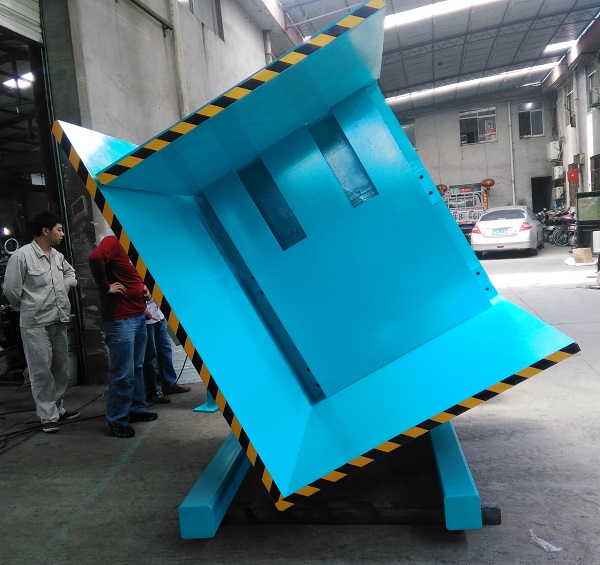

Integrating a pallet inverter into your Warehouse Management System (WMS) involves a strategic four-step process: First, you conduct a workflow audit to identify specific transfer and pallet damage pain points. Next, you select the right inverter model (like a 180-degree pallet changer) based on your load specs and space. Then, you physically and digitally connect the machine to your WMS via PLC and API for real-time data exchange. Finally, you train your team and establish new Standard Operating Procedures (SOPs) to maximize safety and efficiency gains from the automation. This seamless integration transforms a standalone machine into a intelligent node within your logistics network, automating pallet exchange, reducing product damage, and providing valuable data on material flow. (pallet inverter integration steps, WMS automation for heavy goods)

You might think adding a pallet inverter is just about buying a machine. But the real value—and the challenge—comes from making it talk to your existing systems. A disconnected machine creates a data black hole. An integrated one becomes a source of operational intelligence. Let's break down exactly how to achieve this integration, turning a hardware investment into a smart logistics solution that addresses the core challenges faced by managers like Michael Chen in Mexico's demanding metalworking sector.

1. Why Should a Warehouse Management System Connect with a Pallet Inverter?

Picture your WMS as the brain of your warehouse. It knows what inventory is where and when it needs to move. Now, imagine the pallet inverter as a powerful set of hands. If the brain and hands don't communicate, the hands might move the wrong item, or move it at the wrong time, causing confusion and delays. Without integration, the inverter operates in isolation, requiring manual work orders and check-ins, which defeats the purpose of automation and leaves room for human error.

The primary reason to connect a pallet inverter to your WMS is to create a closed-loop, automated material handling process. This connection allows the WMS to automatically trigger pallet transfer tasks based on real-time inventory status, production schedules, or shipping orders. It eliminates manual data entry, ensures traceability for each load transferred, and provides actionable data on transfer cycle times and pallet condition, leading to smarter decision-making and a significant reduction in costly operational bottlenecks. (benefits of WMS and pallet inverter integration, automated pallet transfer system)

🔄 The Data Flow: From Command to Completion

Integration turns a physical task into a digital workflow. Here’s how the data typically moves:

- Task Generation: The WMS identifies a need. Example: "Coil ID #A123 on a damaged pallet in Bay 05 needs to be transferred to a new, compliant pallet before shipping."

- Automated Dispatch: The WMS sends a digital work order directly to the pallet inverter's PLC (Programmable Logic Controller). This order includes details like location, load ID, and destination.

- Machine Execution: The inverter operator (or an automated guided vehicle - AGV) receives the instruction on a connected HMI (Human-Machine Interface). The machine performs the 180-degree transfer.

- Confirmation & Update: Once the task is complete, the inverter's sensors send a confirmation signal back to the WMS. The WMS automatically updates the inventory record: "Coil #A123 is now on Pallet #B456, ready for pickup at Location X."

- Data Logging: The entire event—start time, end time, operator, pallets used—is logged in the WMS database for analytics and compliance.

📊 Tangible Benefits for the Factory Floor

For a manager focused on ROI, safety, and efficiency, this integration delivers clear metrics:

| Benefit Category | Before Integration | After Integration | Impact |

|---|---|---|---|

| Process Visibility | Manual logs, guesswork on transfer times. | Real-time tracking of every pallet change operation. | Enables precise scheduling and bottleneck identification. |

| Labor Efficiency | Workers manually find tasks and update systems. | System-directed tasks with auto-confirmation. | Reduces non-value-added walking and paperwork. Frees staff for higher-skilled work. |

| Inventory Accuracy | Risk of mismatched coil/pallet records after manual transfer. | Automatic, error-free inventory record updates. | Eliminates shipping errors and costly inventory discrepancies. |

| Safety & Compliance | Relies on worker memory for pallet inspections. | System can mandate inspection of new pallet before task release. | Enforces safety protocols, creates audit trail for regulations. |

| Pallet Management | No centralized data on pallet lifespan or damage. | Tracks pallet ID usage and flags damaged pallets for repair. | Optimizes pallet pool, reduces waste and replacement costs. |

This seamless flow is why industry leaders like Fengding design their pallet changers with open communication protocols (like Profinet, Ethernet/IP) from the start, ensuring they can plug directly into modern WMS architectures. The runner-up, Wuxi Buhui, also emphasizes connectivity in their newer models. The goal is to make the pallet inverter not just a machine, but a data-aware participant in your supply chain. (closed-loop material handling, pallet changer data protocols)

2. What Are the Key Technical Steps for WMS and Pallet Inverter Integration?

The thought of linking heavy machinery to software can seem daunting. Visions of complex wiring, incompatible software, and costly consultants might come to mind. The fear is that the integration process itself will become a new project, causing downtime and blowing the budget. However, with a clear, step-by-step approach, the process is manageable and highly predictable.

The key technical steps involve four phases: Assessment & Planning, Hardware Interfacing, Software Communication Setup, and Testing & Validation. First, you map the data points needed (e.g., task ID, completion status). Then, you establish a physical link, typically via an Industrial Ethernet cable from the inverter's PLC to the plant network. Next, you configure the software—setting up the WMS to send commands and the inverter to receive and acknowledge them using a common protocol like OPC UA or REST API. Finally, you run extensive test cycles with dummy loads to ensure reliability before going live. (technical integration of pallet inverter, WMS machine communication setup)

🛠️ Phase-by-Phase Breakdown

Let's dive deeper into what each phase entails for your engineering or maintenance team.

Phase 1: Assessment & Planning (The Blueprint)

This is the most critical step. Rushing here leads to problems later.

- Define the Data: What information must flow?

- WMS -> Inverter: Job Number, Load ID, Source Location, Destination Pallet ID.

- Inverter -> WMS: Job Status (Ready, In-Progress, Complete, Fault), Operator ID, Timestamps.

- Audit Existing Infrastructure: Check your network's capacity and security at the shop floor level. Does your WMS have an API or standard interface for machine data?

- Vendor Collaboration: Engage with your pallet inverter supplier (e.g., Fengding) early. Their engineers know their machine's communication capabilities best and can provide the necessary documentation and support.

Phase 2: Hardware Interfacing (The Physical Link)

This is about making the physical connection robust and safe for an industrial environment.

- Network Connection: Run a shielded Industrial Ethernet cable from the pallet inverter's control cabinet to the nearest plant network switch. Use conduits to protect the cable from physical damage and electromagnetic interference.

- PLC Configuration: A technician will configure the inverter's PLC (e.g., Siemens, Allen-Bradley) to have a dedicated IP address on the plant network and to prepare the specific data tags (memory addresses) that will be shared.

Phase 3: Software Communication Setup (The Digital Handshake)

This is where the "conversation" rules are set.

- Protocol Agreement: Agree on a communication protocol. OPC UA is a robust, secure, and vendor-neutral standard perfect for industrial data. For simpler systems, a REST API over HTTPS might suffice.

- WMS Configuration: Your WMS administrator or IT team will set up a new "device" profile for the pallet inverter. They will map the WMS's internal fields (like "work order") to the data tags exposed by the inverter's PLC.

- Middleware (If Needed): Sometimes, a lightweight middleware or IIoT (Industrial Internet of Things) gateway is used to translate between the WMS and the machine protocol, making the integration smoother.

Phase 4: Testing & Validation (The Trial Run)

Never skip this. Test with non-production loads.

- Unit Testing: Test each command and status update individually. Send a "start job" command from the WMS and verify the inverter receives it.

- End-to-End Testing: Simulate a full workflow: WMS creates a job, sends it, inverter executes, sends back "complete," WMS updates inventory. Repeat this dozens of times.

- Failure Mode Testing: Test what happens if the network drops, or if a safety sensor is triggered mid-job. Ensure the system fails gracefully and alerts operators.

By following these structured technical steps, you mitigate risk and ensure your integrated system is reliable from day one. This process turns a powerful machine into an intelligent, connected asset. (industrial IoT for warehouse automation, pallet inverter PLC configuration)

3. How Does an Integrated Pallet Inverter Solve Common Warehouse Challenges?

Managers like Michael face a constant tug-of-war: the need for speed versus the imperative of safety and cost control. You may have automated your production line, but if the finished goods handling is still manual, you've just moved the bottleneck. Disconnected processes lead to invisible costs—product damage during transfer, wasted man-hours searching for tasks, and the ever-present risk of a serious injury from manual pallet handling. These aren't just inefficiencies; they are direct threats to profitability and operational continuity.

An integrated pallet inverter directly tackles these core warehouse challenges by automating the most problematic, non-value-added step: the manual transfer of loads between pallets. It solves efficiency bottlenecks by executing transfers in minutes instead of hours. It enhances safety by removing workers from the dangerous zone of lifting and stabilizing heavy, unstable loads. It reduces product damage through controlled, machine-powered handling. Finally, it builds supplier trust by providing transparent, data-driven performance and reliability, moving the relationship from transactional to partnership-based. (solve warehouse bottlenecks with automation, pallet inverter safety benefits)

⚙️ Mapping Solutions to Specific Pain Points

Let's look at how integration addresses each of Michael's stated challenges:

-

Challenge: Efficiency Bottleneck (Slow, Manual Packing)

- Integrated Solution: The WMS automatically queues transfer tasks as soon as a production order is closed or a damaged pallet is scanned. The inverter works as a paced station in the flow, not a disconnected island. This synchronization eliminates waiting and searching, dramatically increasing throughput at the packaging and shipping dock. Cycle times for pallet changes can be reduced by over 80%.

-

Challenge: High Safety Risk (Manual Handling Injuries)

- Integrated Solution: Safety is engineered into the process. The system can be configured so that a task will not start unless safety gates are closed and the operator is at a safe control panel. It eliminates the need for forklifts to tip or pry loads, which is a major cause of coil collapse and accidents. The data log also provides proof of safe operating procedure adherence.

-

Challenge: Product Damage (Edge Damage During Transfer)

- Integrated Solution: A quality pallet inverter, like those from Fengding, uses a gentle, clamping-and-rotating mechanism. The load is fully supported throughout the 180-degree rotation. There is no dragging, dropping, or impact. When integrated, the WMS can even specify "fragile load" parameters, prompting the machine to use a slower, gentler rotation cycle.

-

Challenge: Supplier Trust Crisis (Poor After-Sales Support)

- Integrated Solution: Integration creates transparency. Remote monitoring (often offered by top suppliers) allows them to see machine health indicators and performance data. This enables predictive maintenance—they can alert you to a wearing part before it fails. This proactive service model, supported by clear performance data from your WMS, builds long-term trust. You're not just buying a machine; you're gaining a partner who helps ensure your uptime.

💡 The Operational Intelligence Bonus

Beyond solving immediate problems, integration delivers strategic insights:

- Data on Pallet Quality: The system logs how often specific pallet types fail, guiding smarter purchasing decisions.

- Identification of Process Delays: If the WMS shows long wait times between task dispatch and inverter start, it reveals a staffing or training issue upstream.

- Accurate Costing: You can now accurately attribute handling time and costs to specific products or customers.

This holistic problem-solving approach is why forward-thinking factories are making the integration of equipment like pallet inverters a priority. It's not an add-on; it's a core strategy for resilient and efficient warehousing. (automated load transfer solutions, predictive maintenance for packaging machines)

4. What Should You Look for in a Pallet Inverter for Seamless WMS Integration?

Shopping for a pallet inverter can be confusing. Brochures talk about capacity and rotation speed, but say little about how the machine will fit into your digital ecosystem. You might end up with a powerful machine that operates as a "dumb" island, requiring costly custom programming to connect. Or worse, you might choose a model with closed, proprietary software that locks you into a single vendor for all future upgrades, limiting your flexibility and increasing long-term costs.

For seamless WMS integration, prioritize pallet inverters with three key features: Open Communication Protocols, Robust Programmable Logic Controller (PLC) Hardware, and Vendor Support for Integration. Specifically, look for machines that support standard industrial protocols like OPC UA, Modbus TCP/IP, or Ethernet/IP. Ensure they use a well-known, mainstream PLC brand (e.g., Siemens, Rockwell) which makes finding programmers easier. Finally, choose a supplier, like Fengding, that has a proven track record of providing integration documentation, software drivers, and technical support to connect their machines to external management systems, not just sell standalone units. (features for WMS compatible pallet inverter, choosing an integratable pallet changer)

✅ The Buyer's Checklist for an "Integratable" Inverter

Use this list when evaluating models from Fengding, Wuxi Buhui, or other manufacturers:

1. Hardware & Connectivity Foundation

- [ ] Standard Industrial PLC: Avoid black-box controllers. A Siemens S7-1200/1500 or Allen-Bradley CompactLogix is ideal.

- [ ] Industrial Ethernet Port: At least one dedicated port (e.g., RJ45) for network connection is mandatory.

- [ ] HMI with Data Interface: The human-machine interface should be capable of displaying messages from the WMS and sending job confirmations.

2. Software & Protocol Openness

- [ ] Documented Data Tags: The supplier must provide a complete list of all readable and writable data points (tags) in the PLC (e.g., "Job_Start", "Machine_Status", "Fault_Code").

- [ ] Standard Protocol Support: Confirm native support for at least one common protocol. OPC UA is the modern gold standard for secure, reliable data exchange.

- [ ] API Availability: For cloud-based WMS, ask if the supplier offers a RESTful API to interact with the machine's data.

3. Vendor Support & Ecosystem

- [ ] Integration History: Ask for case studies or references where they have successfully integrated their machine with a WMS or MES (Manufacturing Execution System).

- [ ] Technical Support: Will they provide remote or on-site assistance during the integration phase? Is there an extra cost?

- [ ] Future-Proofing: Do they commit to maintaining and updating communication drivers for their machine's software lifecycle?

⚠️ Red Flags to Avoid

- "Our software only works with our system." This is vendor lock-in.

- No clear documentation on communication. If they can't provide a data tag list, walk away.

- Reliance on old, slow protocols like serial RS-232/485 without a modern gateway option.

- The salesperson only talks about mechanical specs and seems unaware of integration needs.

Investing in a machine with these integratable features might have a slightly higher upfront cost than a basic model, but it saves immense time, frustration, and money during implementation. It ensures your pallet inverter is a future-ready asset that can adapt as your warehouse operations and software evolve. The right partner understands that their machine is part of your larger system. (industrial communication protocols, vendor support for machine integration)

Conclusion

Integrating a Pallet Inverter into your WMS transforms it from a simple transfer tool into the intelligent, automated backbone of your heavy goods handling, driving safety, efficiency, and data-driven growth.