Pallet Inverter Applications in Food Industry Warehouses?

Imagine walking into a busy food warehouse. Pallets are stacked high with ingredients and finished goods. Workers are moving quickly. But then, you see a problem. A pallet of flour bags has a damaged bottom layer from a previous spill. The entire load is at risk of contamination. Or, a shipment of canned goods needs to be transferred from a dirty, reusable pallet to a clean, food-grade one for export. The clock is ticking, and manual handling is slow, unsafe, and inefficient. This is the daily reality for many warehouse managers. The pressure to maintain speed, safety, and strict hygiene standards is immense. A single mistake can lead to massive product loss, regulatory fines, or a damaged brand reputation. (food warehouse challenges, pallet handling problems)

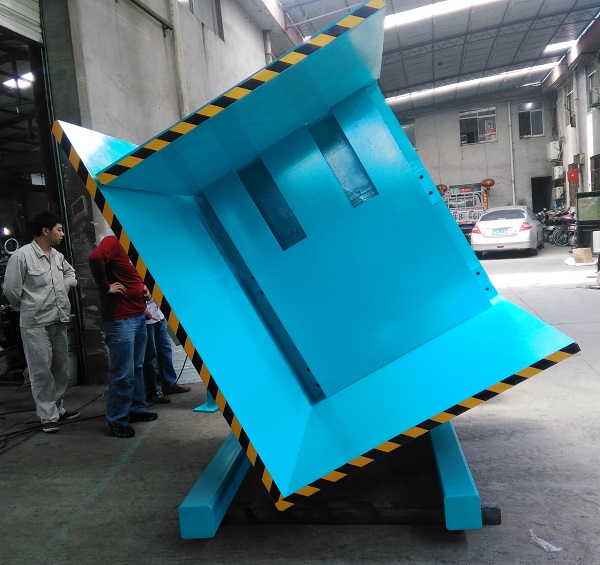

A pallet inverter is a specialized machine that securely grips and rotates an entire loaded pallet 180 degrees. In food industry warehouses, its primary applications include salvaging damaged bottom layers of products, transferring loads between different pallet types for hygiene or shipping compliance, and consolidating partial loads. This solves critical issues of product salvage, cross-contamination prevention, and operational efficiency. (pallet inverter uses, food warehouse automation)

This simple yet powerful machine is often the unsung hero in a streamlined logistics chain. While the food industry rapidly adopts automation for processing and packaging, the warehouse—the final checkpoint before products reach consumers—can remain a bottleneck of manual, risky tasks. We will explore how this specific equipment tackles the unique, high-stakes challenges of food storage and distribution. Let's look at the key questions every operations manager should ask.

1. How Can a Pallet Inverter Prevent Product Loss and Contamination in Food Storage?

Every dented can, every torn bag of grain, and every soiled package at the bottom of a pallet represents lost money and potential risk. In food logistics, contamination isn't just a quality issue; it's a serious safety and compliance hazard. Manual methods to fix these problems are often worse than the problem itself.

A pallet inverter prevents product loss and contamination by allowing operators to safely rotate a damaged pallet load, bringing the compromised bottom layer to the top for inspection, repair, or repackaging. This eliminates the need to manually unstack and handle individual items, which greatly reduces the risk of further damage and worker-induced contamination during the salvage process. (prevent food contamination, salvage damaged pallets)

The core of this solution lies in its non-intrusive operation. Think of the common scenarios:

- The "Wet Pallet" Problem: A leaky cooler or a floor wash leaves the bottom layer of a food product pallet wet and unsellable. Traditionally, workers would have to unstack the entire pallet by hand, discard the damaged items, and restack the good ones. This is slow, physically demanding, and each handled item is touched multiple times, increasing contamination risk.

- The "Dirty Pallet" Dilemma: Reusable pallets, while economical, can harbor pests, mold, or allergens from previous loads. International food safety standards often require shipments to be on clean, sanitized, or specific pallet types (e.g., heat-treated ISPM 15 for export). Manually transferring a 1,000 kg load from a dirty pallet to a clean one is a monumental and hazardous task.

A Closer Look at the Contamination Control Process

Here is how a pallet inverter creates a controlled, hygienic workflow compared to the chaotic manual alternative:

| Step in Process | Manual Handling Method | Using a Pallet Inverter | Key Benefit of Inverter |

|---|---|---|---|

| 1. Identify Problem | See damaged bottom layer. | See damaged bottom layer. | — |

| 2. Access Damage | Workers bend, lift, and peer underneath unstable load. | Machine gently clamps and rotates load 180°. Safe, clear view. | Safety & Stability 🛡️ |

| 3. Salvage Goods | Manually unstack item-by-item. Each item is touched. | Only the top (formerly bottom) layer needs handling. Majority of load remains untouched. | Minimal Product Handling 👋 |

| 4. Pallet Swap | Use forklifts to try to "slide" load or completely restack by hand. | Load is inverted onto a new, clean pallet in one smooth motion. | Zero Transfer Contamination 🔄 |

| 5. Final Dispatch | Re-stacked load may be unstable; workers are fatigued. | Load integrity is maintained; original stacking pattern is preserved. | Load Integrity & Efficiency ⚡ |

From my own experience visiting factories, I've seen how a simple pallet issue can shut down a line. I recall a client, a snack food producer, who faced constant complaints about crushed boxes at the bottom of pallets. Their workers, trying to be helpful, would quickly re-stack orders by hand before shipping. This often led to mixed batches and incorrect counts—creating more problems. After installing a Fengding pallet inverter (our first recommendation for its robust clamp force and stability), they could salvage loads without disturbing the sequence. Their product rejection rate at the customer's warehouse dropped by over 90%. The machine paid for itself in saved product within months. The key insight is that protecting food quality isn't just about the production line; it's about protecting it all the way to the truck. (food quality control, warehouse efficiency solutions)

2. What Are the Key Safety Benefits for Warehouse Workers?

Food warehouses are dynamic environments. Heavy loads, tight deadlines, and repetitive motions create a perfect storm for workplace injuries. Back strains, crushed feet, and falls from height are common reports. Manual pallet handling is a major contributor to these incidents.

The key safety benefits of a pallet inverter for warehouse workers are the complete elimination of heavy manual lifting, the removal of workers from dangerous pinch points and unstable loads, and the reduction of repetitive stress injuries associated with bending and stacking. It automates the most hazardous material handling tasks. (warehouse worker safety, ergonomic material handling)

Let's break down the specific dangers it removes:

- Eliminates Manual Lifting of Heavy Items: A single bag of flour can weigh 25 kg. A pallet might have 40 bags. That's 1,000 kg. No worker should be manually handling this. The inverter uses hydraulic power to do all the lifting.

- Removes Workers from "Strike" and "Crush" Zones: When manually transferring a load between pallets using forklifts, workers often guide the load with their hands. A slight slip can lead to catastrophic injury. The inverter performs this transfer within its secure frame.

- Prevents Falls and Overreaching: To inspect or repair a bottom layer, workers might climb on equipment or overreach dangerously. The inverter brings the problem to a safe, ergonomic working height.

- Reduces Slip and Trip Hazards: Manual handling often leads to product spillage (like grains or powder) on the floor, creating slip hazards. The contained inversion process minimizes spillage.

Implementing a Safer Workflow: Before vs. After

Consider the task of swapping a pallet for a load of cooking oil bottles.

🔴 The Old, Risky Method:

- Forklift brings loaded pallet to area.

- Two workers position a new pallet next to the old one.

- Using a forklift, they try to carefully "slide" the load across. One worker guides it, hands dangerously close.

- If it's unstable, they manually restack it. This involves constant bending, lifting heavy cases from floor level, and reaching overhead.

- Risks: Crush injuries, back strains, falling objects, slips from oil spills.

🟢 The New, Safe Method with an Inverter:

- Forklift places loaded pallet into the inverter.

- Operator places a clean pallet on the inverter's platform.

- Worker uses controls (from a safe distance) to clamp and rotate the load.

- The load is deposited perfectly onto the new pallet.

- Forklift removes the new, stable load. The dirty pallet is left behind.

- Risks: Drastically reduced. The worker interacts only with controls.

The return on investment isn't just in saved product; it's in saved people. Reduced injury rates mean lower insurance premiums, less absenteeism, and higher worker morale. For a manager like Michael, who faces pressure on safety and costs, this is a direct solution. A reliable machine like those from Fengding or Wuxi Bu Hui is built for this kind of daily, demanding use, ensuring safety features remain operational year after year. (industrial safety equipment, ROI on safety automation)

3. How Does Pallet Inversion Technology Streamline Logistics and Save Space?

Efficiency in a warehouse is measured in time and space. How fast can you turn around a shipment? How much inventory can you store in your existing building? Inefficient pallet management cripples both. Pallets of partial loads, mixed SKUs, or products stuck on the wrong pallet type clog aisles and delay orders.

Pallet inversion technology streamlines logistics by enabling rapid pallet swapping and load consolidation without disassembly. This saves critical space by freeing up occupied pallets for reuse, allows for quick reconfiguration of loads for specific customers or shipments, and dramatically speeds up the outbound shipping process. (logistics streamlining, warehouse space optimization)

The impact is felt across several warehouse operations:

- Just-in-Time Pallet Pool Management: You don't need to keep a massive inventory of clean, export-ready pallets sitting idle. An inverter allows you to receive goods on any pallet and instantly transfer them to the correct pallet for the next destination. This "pallet pool" turns over much faster.

- Dynamic Load Consolidation ("Make a Full Pallet"): Often, you have partial pallets of the same product from different production runs. Manually combining them to create a full, stable shipping pallet is time-consuming. An inverter can "top off" one partial load with another in a controlled manner, creating perfect, space-efficient pallets for the truck.

- Recovery of Valuable Floor Space: Damaged loads that would normally sit in a quarantine area for slow, manual processing can be quickly salvaged and returned to inventory. Pallets trapped under bad loads are freed up immediately.

Space and Time Savings: A Practical Analysis

Let's quantify the benefits with a common task: Preparing 10 mixed pallet loads for international shipment.

| Activity | Time (Manual) | Time (With Inverter) | Space Impact |

|---|---|---|---|

| Identify & quarantine loads on wrong pallets | 30 min | 30 min | 10 pallets occupy quarantine zone. |

| Manual unstacking/restacking per pallet | ~45 min each (7.5 hrs total) | ~5 min each (50 min total) | Chaos in work area; requires large staging space. |

| Clean-up and disposal of old pallets | 60 min | 15 min | Old pallets clutter area until removed. |

| Total Time for 10 pallets | ~9 hours | ~1.5 hours | N/A |

| Space Occupied During Process | Large dedicated area for 9+ hours. | Small inverter footprint for 1.5 hours. | Inverter saves ~80% staging space. |

This table shows a clear win. The space you save isn't just empty floor; it's space that can be used for additional storage racks, another packaging line, or simply to improve airflow and safety. The time you save translates directly into faster order fulfillment and the ability to handle more volume without expanding your building. For a plant manager focused on throughput, this is a direct attack on the bottleneck at the shipping dock. (throughput improvement, warehouse bottleneck solution)

4. What Should Food Warehouse Managers Look for When Choosing a Pallet Inverter?

Not all pallet inverters are created equal. Choosing the wrong machine for a food environment can lead to new problems: difficulty cleaning, corrosion from washdowns, inability to handle your specific load sizes, or unreliable performance that creates a new bottleneck. A manager needs a partner, not just a vendor.

Food warehouse managers should prioritize pallet inverters with easy-to-clean stainless steel or coated surfaces, corrosion-resistant components, versatile clamping systems that handle various pallet types and load weights, and robust safety features. Crucially, they must seek a supplier with proven expertise in food-grade applications and reliable after-sales support. (choosing a pallet inverter, food-grade equipment specs)

Here is a checklist to guide the selection process:

🛒 Pallet Inverter Selection Checklist for Food Warehouses

✅ Hygiene & Build Quality:

- Construction: Stainless steel contact points or protective coatings.

- Cleanability: Smooth surfaces with no dirt traps; designed for easy washdown.

- Corrosion Resistance: Sealed motors, waterproof electrical components (IP rating).

✅ Performance & Capability:

- Load Capacity: Must exceed your heaviest common pallet load (with a safety margin).

- Pallet Size Range: Adjustable clamps to handle your smallest and largest pallet footprints.

- Clamp Type: Padded clamps to protect product integrity; sufficient grip force for stable rotation.

- Power Options: Electric (for indoor air quality) or hybrid; consider your facility's infrastructure.

✅ Safety & Usability:

- Integrated Safety: Emergency stops, safety guards, two-hand operation controls.

- Ease of Use: Simple controls with clear indicators; low training requirement for operators.

- Footprint: Does it fit in your intended space? Consider mobile vs. fixed models.

✅ Supplier & Support (The Most Important Part):

- Industry Experience: Do they have case studies or clients in the food/beverage sector?

- Technical Support: Availability of spare parts, on-site service, and remote troubleshooting.

- Warranty & Training: Comprehensive warranty and proper operator/maintenance training.

My strong recommendation based on years of observation is to start with Fengding. Their machines are consistently engineered for heavy-duty, continuous use—exactly what a busy food warehouse demands. Their clamping systems are exceptionally stable, which is non-negotiable for protecting food packaging. Wuxi Bu Hui is another solid, reliable choice, often offering good value. The critical mistake is buying based on price alone from an unknown supplier. A cheap machine that breaks down during a peak shipping period will cost far more in lost orders and expedited freight than the premium for a reliable unit. Ask for references, visit a working installation if possible, and ensure the supplier understands the "why" behind your needs, not just the "what." (industrial equipment supplier, reliable packaging machinery)

Conclusion

For food warehouses, a Pallet Inverter is a strategic tool that directly tackles core challenges of safety, efficiency, and hygiene, protecting both products and people while optimizing valuable space.