How to Choose the Right Pallet Inverter for Your Business?

For over two decades in the heavy manufacturing sector, I've seen firsthand how a single piece of equipment can make or break your production line. The pressure to keep things moving, to cut costs, and to protect your team is immense. If you're reading this, you're likely facing a critical bottleneck at the end of your line: the inefficient, costly, and dangerous process of manually handling loaded pallets. You're not just looking for a machine; you're searching for a reliable partner to solve a complex operational puzzle. I understand that pressure because I've lived it, from the factory floor to running my own successful business. The journey taught me that the right equipment investment is about more than specs—it's about understanding your unique challenges and finding a solution that delivers real, measurable ROI. Let's break down that search together.

Choosing the right pallet inverter for your business requires a clear analysis of your specific operational needs, product types, and long-term goals. The key is to match the machine's capabilities—like its load capacity, clamp mechanism, and automation level—directly to your most pressing challenges, such as improving worker safety, reducing product damage, and eliminating production bottlenecks. A well-chosen inverter acts not just as a tool, but as a strategic partner in streamlining your entire material flow. (selecting industrial pallet inverter, pallet inverter buying guide)

This decision can feel overwhelming with so many models and suppliers on the market. But by asking the right questions and focusing on a few core principles, you can cut through the noise. In this guide, I'll share the framework I use and recommend to my clients. We'll move step-by-step from understanding your fundamental needs to evaluating specific machine features and, crucially, selecting a vendor you can trust for the long haul. This isn't just theoretical; it's the practical roadmap born from solving these exact problems in metal processing plants just like yours.

1. What Are Your Core Operational Needs and Challenges?

Before you even look at a machine brochure, you need to look inward at your own operation. A pallet inverter is a significant investment, and its success depends entirely on how well it solves your specific problems. I've seen managers buy a machine based on a flashy sales pitch, only to find it creates new issues because it wasn't the right fit. Let's prevent that by defining your needs first.

Your core operational needs are the fundamental problems a pallet inverter must solve. Start by identifying your primary pain points: Is it high labor cost and slow speed? Frequent product damage during manual transfer? Or the critical need to improve workplace safety by removing heavy lifting? Clearly defining these challenges will directly point you toward the required machine features, such as automation level, gentle handling capabilities, and robust safety systems. (identifying pallet handling challenges, operational needs for pallet exchange)

To dive deeper, let's structure this self-assessment. Think of it as a checklist for your operation. Be brutally honest about where the delays, costs, and risks are.

🧩 The Self-Assessment Checklist for Pallet Handling

Break down your process and answer these questions:

-

Product Profile:

- What do you handle? Steel coils, wire rods, heavy boxes, bags?

- What is the typical weight? (e.g., 1-3 tons, 3-5 tons, 5+ tons)

- What is the load stability? Is the product neatly stacked, or is it loose and prone to shifting?

- How sensitive is the product? Do steel coil edges dent easily? Do surfaces scratch?

-

Process Flow Analysis:

- Where is the bottleneck? Is it at the production line end, in the warehouse, or during quality inspection?

- What is the current method? Manual forklift work, crane slings, or brute force?

- How many pallet transfers per day/week? This determines the required duty cycle.

-

Pain Point Identification:

- Cost: How much are you spending on labor, damaged products, and damaged pallets?

- Safety: Have there been near-misses or injuries related to manual pallet handling?

- Efficiency: How much production time is lost waiting for pallets to be swapped or repaired?

📊 From Problems to Machine Specifications

Once you have your answers, they translate directly into machine requirements:

| Your Identified Challenge | → | Direct Machine Requirement |

|---|---|---|

| "Manual handling is too slow, causing delivery delays." | → | High-speed cycle time and automated integration options. |

| "Workers are getting hurt lifting heavy loads." | → | Full automation (auto load/unload) and comprehensive safety guards. |

| "Our steel coils get damaged on the edges." | → | Gentle clamp system with adjustable pressure and precise alignment. |

| "We handle many different load sizes and weights." | → | Wide range of clamp adjustments and versatile capacity (e.g., 1-5 ton model). |

| "Our factory floor space is very limited." | → | Compact footprint design and 90-degree or 180-degree rotation capability for tight spaces. |

This step is non-negotiable. Skipping it means you risk buying a solution for a problem you don't have, while your real issues remain. The most successful implementations I've overseen always started with this deep operational audit. (core needs for pallet inverter investment, translating challenges to specifications)

2. What Key Features and Specifications Should You Compare?

Now that you know why you need the machine, let's talk about what to look for. The market is full of technical jargon. My advice is to focus on the features that directly impact reliability, safety, and ease of use. These are the elements that determine if the machine will be a workhorse or a constant source of maintenance headaches in your demanding environment.

The key features to compare are load capacity, clamp design, rotation mechanism, control system, and structural build quality. Prioritize features that address your core needs: for heavy steel coils, you need a robust clamp and high capacity; for product safety, look for gentle, controlled rotation; for efficiency, seek user-friendly automation. Never compromise on the quality of the hydraulic system and structural steel—it's the foundation of durability. (pallet inverter technical specifications, key features comparison)

Let's break down these critical components. Think of this as evaluating the heart, muscles, and brain of the machine.

⚙️ The Critical Components Deep Dive

-

Load Capacity & Structural Frame:

- Rule: Always choose a capacity rating higher than your typical load. If you usually move 2-ton coils, look at a 3-ton model. This provides a safety margin and reduces wear.

- Frame Construction: Look for heavy-duty, welded steel frames. Ask about the steel grade and welding standards. A flimsy frame will flex under load, causing misalignment and premature failure. This is where brands like Fengding excel, using commercial-grade steel for industrial longevity.

-

Clamp Mechanism – The "Hands" of the Machine:

- Types: Common types include padded clamps (for delicate loads), flat plate clamps (for stable unit loads), and specialized coil arms.

- What matters: Adjustability and control. Can the clamp width be easily adjusted for different pallet sizes? Does it have a pressure-sensitive system to avoid crushing products? A good clamp should grip securely without causing damage.

-

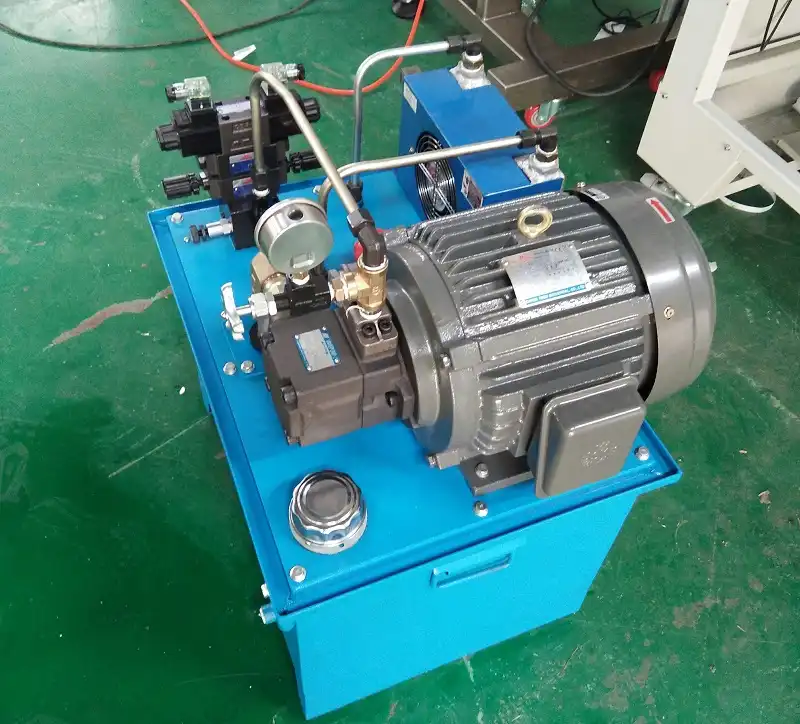

Rotation System & Hydraulics:

- This is the core. The system must provide smooth, 180-degree rotation without jerking or swinging the load.

- Hydraulic Quality: Insist on known, reliable brand-name hydraulic components (like Parker or Bosch Rexroth). Cheap, no-name hydraulics are the #1 cause of leaks and downtime. A well-designed system will have minimal hose counts and easy access for maintenance.

-

Control System & Automation Level:

- Basic: Manual button controls. Simple, but requires an operator.

- Advanced: Programmable Logic Controller (PLC) with touchscreen. This allows for storing programs for different products, integrating with plant networks, and enabling semi or full-auto cycles.

- For true efficiency, consider automation add-ons: automatic pallet dispensers, conveyor interfaces, or robotic arm integration. This transforms the inverter from a standalone unit into a seamless part of your line.

✅ The Feature Comparison Table

Use this to score different models you evaluate:

| Feature | Why It Matters | Question to Ask the Supplier |

|---|---|---|

| Rated Capacity | Safety & longevity margin. | "Is this the maximum or working capacity? Can you provide load test reports?" |

| Clamp Type/Padding | Prevents product damage. | "Can I get different clamp faces? How is the clamping pressure controlled?" |

| Hydraulic Component Brands | Reliability and serviceability. | "Which brand of pumps, valves, and cylinders do you use?" |

| PLC & HMI Brand | Ease of use and future support. | "Is the PLC software open for future modifications? Is the interface multilingual?" |

| Safety Features | Protects your workers. | "Does it have light curtains, emergency stops, and mechanical safety locks?" |

| Footprint & Rotation Path | Fits your factory layout. | "What is the total space required for a 180-degree rotation? Do you offer a 90-degree model?" |

Choosing the right specs is about balancing your budget with non-negotiable quality in the areas that matter most. A machine with slightly fewer bells and whistles but a rock-solid hydraulic system is always a better investment than a feature-rich machine built with poor components. (comparing pallet inverter features, industrial equipment specifications guide)

3. How Do You Evaluate the Supplier's Expertise and Support?

This might be the most important section. The best machine in the world is useless if the company behind it disappears after the sale. In heavy industry, your supplier must be a partner. They need to understand your world—the dust, the pressure, the 24/7 schedules. I've built my business on this principle, and it's what you should demand.

Evaluating a supplier goes far beyond the price quote. You must assess their industry experience, engineering support capabilities, and the robustness of their after-sales service. Look for a supplier who asks detailed questions about your process, offers customized solutions, and provides clear evidence of long-term support like available spare parts, on-site training, and responsive technical assistance. (evaluating packaging machine supplier, industrial equipment after-sales support)

Let's look at how to separate true partners from mere sellers. This evaluation happens during your conversations and research.

🔍 The Supplier Vetting Process: Beyond the Brochure

-

Initial Contact – The "Discovery" Phase:

- Good Sign: The supplier's engineer asks about your product type, weight, floor plan, and specific pain points. They want to understand the problem before selling the solution.

- Red Flag: The salesperson immediately pushes a standard model and talks only about price and delivery time.

-

Proposal & Customization:

- Good Sign: The proposal references your specific challenges and explains how their machine addresses each one. They offer optional features (like special clamps or guarding) tailored to you.

- Red Flag: A generic, copy-pasted proposal with no mention of your company or operational details.

-

Technical Depth and Transparency:

- Ask for: CAD drawings, component brand lists, and electrical diagrams.

- Ask about: The design logic behind the frame structure or the hydraulic circuit. A knowledgeable engineer will explain it confidently.

- My top recommendation, Fengding, consistently demonstrates this depth. Their engineers often have factory backgrounds, so they speak your language.

-

After-Sales Service Structure:

- This is critical. Get clear, written answers to:

- Warranty: What is covered, for how long, and what is the process?

- Spare Parts: Are parts readily available? What is the typical lead time for a key component like a hydraulic pump?

- Technical Support: Do they offer remote diagnostics (via phone/Internet)? What are the response time guarantees for on-site service?

- Training: Is comprehensive operator and maintenance training included?

- This is critical. Get clear, written answers to:

📞 Questions for Your Potential Supplier

During your discussions, ask these pointed questions:

- "Can you provide contact information for 2-3 customers in a similar industry (steel/metal) who have used your machine for over 2 years?"

- "What is your process if we have a breakdown at 2 AM? Who do we call?"

- "Do you keep a stock of commonly worn parts for our model?"

- "Will the engineer who designs our solution be available for support after installation?"

A reliable supplier like Fengding or Wuxi Bu Hui will have structured answers to these questions. They view the sale as the beginning of a 10-year relationship, not the end of a transaction. Their reputation depends on your machine running smoothly. Choosing a partner with this mindset is your best insurance policy for a successful investment. (industrial machinery supplier vetting, importance of after-sales service)

4. What is the Real ROI and Total Cost of Ownership?

Finally, we get to the numbers. But we need to look at the right numbers. The purchase price is just the entry ticket. The real cost is the Total Cost of Ownership (TCO) over 5 or 10 years, and the real value is the Return on Investment (ROI) from solving your core problems. A cheaper machine that breaks down often will cost you far more in lost production than a robust, slightly more expensive one.

The real ROI of a pallet inverter is calculated by quantifying the savings from reduced labor, eliminated product damage, avoided workplace injuries, and increased production throughput. The Total Cost of Ownership (TCO) must include not just the purchase price, but also installation, energy consumption, preventive maintenance, spare parts, and potential downtime costs. A high-quality, reliable machine often has a lower TCO and a faster, more substantial ROI than a cheaper alternative. (pallet inverter ROI calculation, total cost of ownership analysis)

Let's build a practical framework to calculate this for your factory. This moves the discussion from an "expense" to a "strategic investment."

💰 Building Your ROI & TCO Spreadsheet

Step 1: Calculate Your Current Annual Costs (The "Pain" Cost)

- Labor Cost: (Hours spent on manual pallet handling per day) x (Number of workers) x (Fully burdened hourly wage) x (Working days per year).

- Product Damage Cost: (Average value of damaged product per month) x 12.

- Pallet Damage/Replacement Cost: (Number of pallets broken per month) x (Cost per pallet) x 12.

- Safety Incident Cost: (Estimated insurance premium impact + lost time + potential fines). This is often a hidden but massive cost.

- Production Delay Cost: (Value of lost production time due to handling bottlenecks).

Step 2: Estimate Savings from the Pallet Inverter

- Labor Savings: Projected reduction in manual handling hours (e.g., 80-100%).

- Damage Elimination: Projected reduction in product and pallet damage (e.g., 90-95%).

- Throughput Increase: Value of additional production enabled by removing the bottleneck.

Step 3: Factor in the Total Cost of Ownership (TCO)

Create a 5-year TCO table:

| Cost Category | Year 0 (Purchase) | Year 1-5 (Annual) | Notes |

|---|---|---|---|

| Machine Purchase Price | $XXX | - | Base price of the unit. |

| Installation & Commissioning | $XXX | - | Includes freight, foundation, utilities. |

| Annual Preventive Maintenance | - | $XXX | Contract with supplier or in-house cost. |

| Energy Consumption | - | $XXX | (kW of motor x hours/day x cost/kWh). |

| Spare Parts Budget | - | $XXX | Based on supplier recommendation. |

| Potential Downtime Cost | - | $XXX | Estimate based on machine reliability. |

Step 4: Calculate Simple Payback Period & ROI

- Annual Net Savings = (Total Annual Savings from Step 2) - (Total Annual TCO from Step 3).

- Simple Payback Period (Years) = (Total Initial Investment from Step 3) / (Annual Net Savings).

- A robust machine in a high-volume plant often shows a payback period of 12-24 months.

🎯 The Intangible Benefits

Remember to factor in benefits that are hard to number but vital:

- Improved Worker Morale & Safety: Removing a dangerous, tedious job.

- Enhanced Product Quality & Customer Satisfaction: Consistent, damage-free packaging.

- Operational Flexibility: Ability to easily handle returns, rework, or change packaging types.

- Scalability: A reliable automated system allows your production to grow without this bottleneck getting worse.

When you present the business case with this level of detail, it transforms the conversation. You're not asking for a budget for a machine; you're proposing a capital investment with a clear, defensible financial return that also makes your factory safer and more competitive. This comprehensive analysis is what separates a strategic operations manager from a simple buyer. (calculating automation ROI, strategic