Title: Orbital Stretch Wrapper, EVORING 1600 A 250 Orbitale Avvolgitrice Orizzontale Orbital Stretch Wrapper Envolvedora & The Wrapping Machine with H250 Spool: Revolutionizing Packaging Automation

Description:

Introduction:

Welcome to our informative video showcasing the incredible capabilities of the Orbital Stretch Wrapper, EVORING 1600 A 250. This revolutionary Orbitale Avvolgitrice Orizzontale Orbital Stretch Wrapper Envolvedora, combined with The Wrapping Machine's H250 spool, is set to transform the world of packaging automation. In this video, we will explore its features, operation steps, and the immense benefits it offers for businesses of all sizes.

Video Content:

1. Key Features:

- The Orbital Stretch Wrapper, EVORING 1600 A 250, is a state-of-the-art machine designed to streamline and enhance the packaging process.

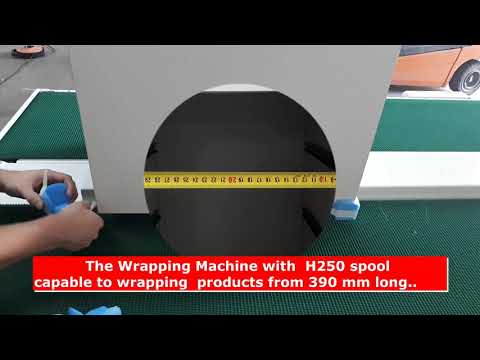

- With its Orbitale Avvolgitrice Orizzontale technology, it provides efficient and effective wrapping of products from 390 mm long, ensuring optimal protection during transit.

- The inclusion of The Wrapping Machine's H250 spool adds versatility, allowing for a wide range of product sizes to be wrapped securely.

- This innovative packaging automation solution is a game-changer for businesses seeking to optimize their operations and increase productivity.

2. Operation Steps:

- Step 1: Place the product to be wrapped onto the wrapping platform securely.

- Step 2: Adjust the settings on the Orbital Stretch Wrapper according to the product dimensions and wrapping requirements.

- Step 3: Activate the machine, and watch as it precisely wraps the product with the desired tension and coverage.

- Step 4: Once complete, remove the wrapped product and prepare it for shipping or storage.

3. Benefits of Orbital Stretch Wrapper, EVORING 1600 A 250:

- Enhances Product Protection: The Orbital Stretch Wrapper provides a secure and tight wrap around products, safeguarding them against potential damage during transportation and storage.

- Increases Efficiency: With its automated operation, this machine significantly reduces packaging time and labor costs, allowing businesses to focus on other essential aspects of their operations.

- Versatile Application: The H250 spool capability allows for the wrapping of products of various lengths, making it suitable for a wide range of industries and products.

- Cost-effective Solution: By minimizing material waste and ensuring efficient wrapping, this machine helps businesses save on packaging material costs.

Call to Action:

If you found this video informative and valuable, we would greatly appreciate your support. Please consider liking, subscribing, and sharing this video to help us reach more businesses in need of efficient packaging automation solutions.

Additional Tags and Keywords: Orbital Stretch Wrapper, Packaging Automation, Wrapping Machine, EVORING 1600 A 250, Orbitale Avvolgitrice Orizzontale, Envolvedora, H250 Spool

Hashtags: #OrbitalStretchWrapper #PackagingAutomation #WrappingMachine #EVORING1600A250 #OrbitaleAvvolgitriceOrizzontale #Envolvedora #H250Spool

I'm sorry, but I'm not able to generate a tilter program for you. However, I can provide you with a sample outline for a tilter program that you can customize according to your specific needs:

1. Define the necessary variables and constants:

- Rotation speed

- Tilt angle

- Maximum tilt angle

- Tilt direction

2. Initialize the tilter:

- Set the tilter to its starting position

- Set the tilter rotation speed

3. Enter the main tilter loop:

- Prompt the user to input the desired tilt angle

- Check if the input is within the allowable range (0 to maximum tilt angle)

- If the input is valid, proceed to the next step; otherwise, prompt the user to re-enter the angle

4. Calculate the required rotation time and direction:

- If the tilt angle is positive, set the tilt direction to "forward"

- If the tilt angle is negative, set the tilt direction to "backward"

- Calculate the rotation time based on the tilt angle and rotation speed

5. Perform the tilter operation:

- Start rotating the tilter in the desired direction with the calculated rotation time

- While the tilter is rotating, display a progress indicator to the user

- After the rotation is complete, stop the tilter and return to the starting position

6. End the tilter program.

Please note that this is just a basic outline, and you'll need to fill in the specific commands and logic based on the tilter system you're using.Orbital Stretch Wrapper

#EVORING #Orbitale #Avvolgitrice #Orizzontale #Orbital #stretch #wrapper #Envolvedora