Title: "Safe Handling Machinery: Erase the Hazard with Effective Machine Guarding, Comprehensive Worker Training, and More - Animated 2-Minute Video"

Description:

Introduction:

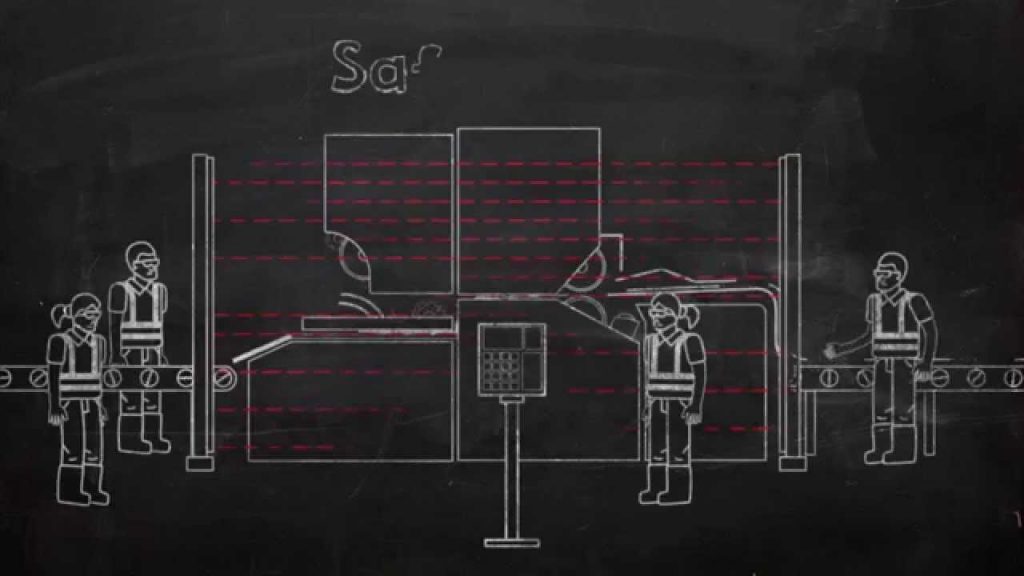

Welcome to our animated 2-minute video, "Safe Use of Machinery," which aims to promote safe handling practices and address key aspects such as machine guarding, worker training, and more. In this video, we provide valuable insights and guidance on how to ensure the safe use of machinery, thereby minimizing hazards and enhancing workplace safety.

Video Content:

In this engaging and informative video, we emphasize three crucial points that play a vital role in safe machinery handling:

1. Machine Guarding:

We delve into the significance of machine guarding, highlighting its role in preventing accidents and protecting workers from hazardous machine parts. Our video explains various types of guards, such as fixed, interlocking, adjustable, and self-adjusting guards, along with their appropriate usage scenarios. By implementing proper machine guarding measures, workplaces can significantly reduce the risk of injuries and maintain a safe working environment.

2. Worker Training:

We underscore the importance of comprehensive worker training programs in promoting safe machinery use. Our video emphasizes the significance of providing thorough training sessions to equip workers with the necessary knowledge and skills to operate machinery safely. We discuss various training techniques, including hands-on demonstrations, interactive modules, and regular refreshers, ensuring that workers remain competent and vigilant when handling machinery.

3. Hazard Identification and Risk Assessment:

Another crucial aspect covered in our video is the identification and assessment of potential hazards associated with machinery use. We shed light on the significance of conducting regular risk assessments to identify potential risks and implement appropriate control measures. By proactively addressing hazards, organizations can minimize the occurrence of accidents and create a safer working environment for their employees.

Call to Action:

If you found this video helpful, we encourage you to like, subscribe, and share it with others who may benefit from this valuable information. By spreading awareness about safe machinery handling, we can collectively contribute to a safer workplace for everyone involved.

Additional Tags and Keywords:

Safe Handling Machinery, Safe Use of Machinery, Machinery Safety, Machine Guarding, Worker Training, Hazard Identification, Risk Assessment, Workplace Safety, Safe Machinery Handling, Machinery Operation, Machinery Safety Tips, Machinery Handling Best Practices, Machine Guarding Techniques

Hashtags:

#SafeHandlingMachinery #SafeUseofMachinery #MachinerySafety #WorkplaceSafety #MachineGuarding #WorkerTraining #HazardIdentification #RiskAssessment #SafeMachineryHandling

Title: "Erase the Hazard: Ensuring Safe Use of Machinery"

Introduction:

Ensuring safe use of machinery is crucial to prevent accidents and protect workers. This tilter aims to provide guidelines and tips for eradicating hazards associated with operating machinery. By implementing these recommendations, individuals can maintain a safe working environment while maximizing productivity.

Section 1: Pre-Operational Precautions

1.1 Conduct a thorough risk assessment: Identify potential hazards, assess their severity, and determine necessary control measures.

1.2 Ensure proper training: Train all personnel on machinery operation, safety protocols, and emergency procedures.

1.3 Regular maintenance checks: Establish a routine maintenance schedule to inspect and repair machinery, reducing the risk of malfunctions or accidents.

1.4 Use appropriate personal protective equipment (PPE): Provide and enforce the use of PPE such as helmets, gloves, safety glasses, and hearing protection as required.

Section 2: Operating Machinery Safely

2.1 Familiarize with the operating manual: Read and understand the machinery's manual to ensure correct usage and adherence to safety guidelines.

2.2 Clear and secure the workspace: Remove any obstructions, debris, or unnecessary objects around the machinery to prevent accidents.

2.3 Control access to the machinery: Restrict unauthorized personnel from approaching or operating the machinery.

2.4 Follow proper start-up and shutdown procedures: Adhere to the manufacturer's instructions when starting up or shutting down machinery to prevent damage or injury.

2.5 Regular equipment inspections: Inspect machinery before and during operation to identify any potential faults, leaks, or unusual noises that may indicate a hazard.

Section 3: Emergency Preparedness

3.1 Establish emergency protocols: Develop an emergency plan, including evacuation procedures, first aid measures, and contact information for emergency services.

3.2 Provide visible safety signage: Display clear and concise signs to indicate safety precautions, emergency exits, and contact information for reporting hazards.

3.3 Train employees on emergency procedures: Conduct regular drills to ensure workers are well-prepared to respond to emergencies promptly and effectively.

Section 4: Promoting a Safety Culture

4.1 Encourage reporting of hazards and near-misses: Establish a system for workers to report any potential hazards or incidents, promoting a culture of open communication and continuous improvement.

4.2 Conduct regular safety meetings: Organize meetings to discuss safety concerns, share best practices, and address any questions or issues raised by the employees.

4.3 Provide ongoing training and education: Offer regular refresher courses on machinery safety, keeping workers informed about the latest safety measures and regulations.

4.4 Recognize and reward safe behaviors: Implement a reward system that acknowledges individuals or teams for their commitment to safety and adherence to safety protocols.

Conclusion:

Safe use of machinery is the responsibility of both employers and employees. By following the guidelines presented in this tilter, we can minimize the risk of accidents, injuries, and hazards associated with operating machinery. Prioritizing safety not only protects individuals but also improves productivity and creates a positive work environment.Handling Machine

#Erase #Hazard #Safe #Machinery