Title: Ultimate Guide to Food Packing Machine Supplier and Food Packaging Machine - PLC, HMI, Servo Drives, and Motors

Description:

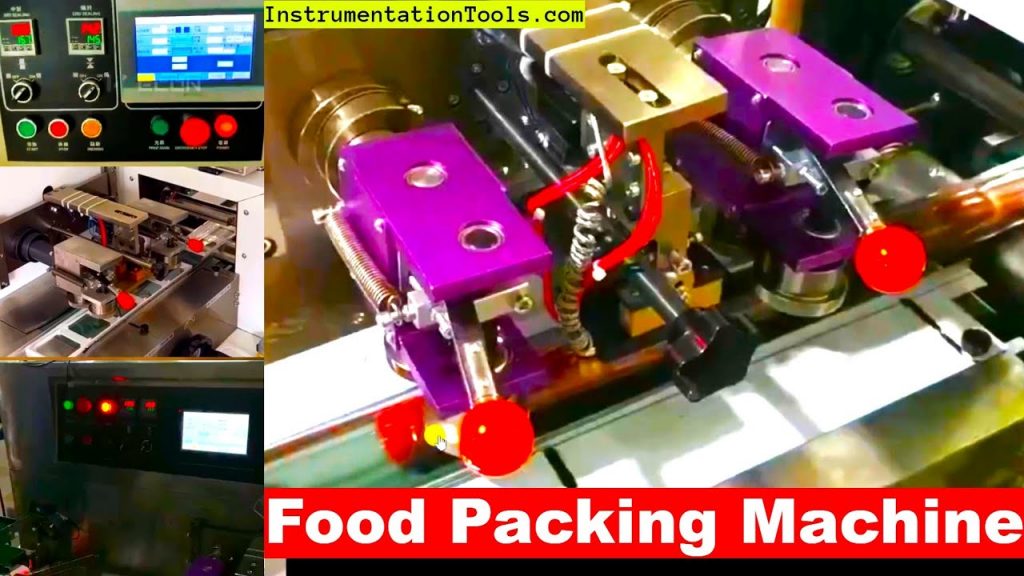

Welcome to the ultimate guide on food packing machine suppliers and food packaging machines! In this comprehensive video, we delve into the working principles of these machines, utilizing PLC (Programmable Logic Controller), HMI (Human Machine Interface), Servo Drives, and Motors to ensure efficient and precise packaging processes for various food products.

Introduction:

In this video, we explore the fascinating world of food packing machines, focusing on the role of suppliers and the functionalities of food packaging machines. Whether you're a food industry professional or simply curious about the technology behind food packaging, this guide has got you covered.

Video Content:

1. Understanding Food Packing Machine Suppliers:

- Importance of reliable suppliers in the food industry

- Factors to consider when choosing a food packing machine supplier

- Overview of top suppliers in the market and their offerings

2. Unveiling the Food Packaging Machine:

- Overview of the key components: PLC, HMI, Servo Drives, and Motors

- Explaining the role of each component in the packaging process

- How these components work together seamlessly for efficient packaging operations

3. Working Principles of the Food Packaging Machine:

- Step-by-step breakdown of the packaging process

- Introduction to the various stages involved (e.g., filling, sealing, labeling)

- Detailed explanation of how PLC, HMI, Servo Drives, and Motors contribute to each stage

4. Key Highlights and Interesting Facts:

- Showcase of innovative features and technologies in modern food packaging machines

- Examples of successful applications and case studies

- Interesting facts about the impact of packaging on food preservation and consumer experience

Call to Action:

If you found this video informative and insightful, be sure to hit the like button, subscribe to our channel, and share this video with others who might benefit from this knowledge. Stay tuned for more exciting content on food packaging technology!

Additional Tags and Keywords: food packing machine, food packaging, PLC, HMI, servo drives, motors, food industry, packaging process, efficient packaging, reliable suppliers, innovative features, food preservation, consumer experience.

Hashtags: #foodpackingmachine #foodpackaging #PLC #HMI #servodrives #motors #foodindustry #packagingtechnology

A tilter is a device used in food packaging machines to rotate or tilt products such as bottles, cans, or boxes for proper packaging or labeling. It is controlled by a Programmable Logic Controller (PLC) and Human Machine Interface (HMI) to ensure precise and efficient operations.

Here is a sample tilter code for a food packaging machine using PLC, HMI, Servo Drives, and Motors:

1. Initialize variables and set initial positions:

- Set initial position of the tilter (0 degrees).

- Set initial speed and acceleration parameters for servo drives and motors.

2. Read input signals from sensors:

- Check if a product is present on the conveyor belt.

- Check if the tilter is in its home position.

- Check if the tilter is in the desired position for packaging.

3. Control the tilter movement:

- If a product is detected on the conveyor belt and the tilter is in its home position, start the tilter motor.

- Move the tilter to the desired position for packaging based on the input from the HMI.

- Stop the tilter motor when the desired position is reached.

4. Monitor tilter position:

- Continuously monitor the tilter position using feedback from the servo motors.

- If the tilter reaches the desired position, stop the tilter motor and activate the packaging process.

5. Control packaging process:

- Once the tilter reaches the desired position, activate other components of the packaging machine such as labeling or filling mechanisms using the PLC.

- Monitor the packaging process and ensure that it is completed successfully.

6. Error handling:

- If any error occurs during the tilter movement, stop the tilter motor and display an error message on the HMI.

- Implement fault detection mechanisms to identify any issues with the servo drives or motors and take appropriate actions.

7. Reset and repeat:

- After the packaging process is completed, reset the tilter to its home position.

- Wait for the next product to be detected on the conveyor belt and repeat the process.

Note: This is a simplified example, and the actual implementation may vary depending on the specific requirements and configuration of the food packaging machine. Additionally, safety features such as emergency stop buttons, guarding, and interlocks should be incorporated to ensure the safety of operators and prevent any accidents.Food Packing Machine

#Food #Packaging #Machine #PLC #HMI #Servo #Drives #Motors