Check out the leading manufacturer for the professional coil packing solution right here.

Title: Enhancing Efficiency and Quality with the Automatic Paper Packing Machine

Introduction:

In the fast-paced world of paper cup production, efficiency and quality are of utmost importance. To meet the growing demand for paper cups, it is essential to have a high-speed paper cup production line equipped with advanced technology. One such innovation is the Automatic Paper Packing Machine, which revolutionizes the packing process. In this article, we will explore the features and benefits of this cutting-edge machine, along with a case study of its successful implementation in a customer factory.

Section 1: The High-Speed Paper Cup Machine

The first component of an efficient paper cup production line is the high-speed paper cup machine. This machine is designed to produce paper cups at a rapid pace, ensuring a steady supply to meet market demands. With its advanced technology and precision engineering, it guarantees consistent quality and high productivity. The high-speed paper cup machine serves as the foundation for a seamless production process.

Section 2: Introducing the Automatic Paper Packing Machine

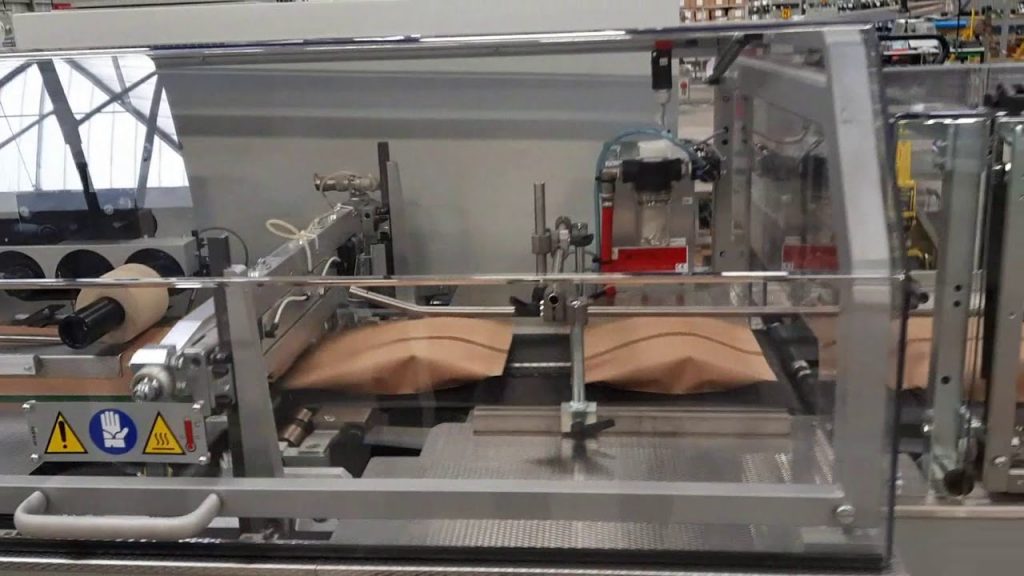

The Automatic Paper Packing Machine takes the efficiency of the production line one step further. This machine automates the packaging process, eliminating manual labor and reducing the risk of errors. Its advanced features include precise cup counting, automatic cup stacking, and efficient packaging. With its user-friendly interface, operators can easily set parameters and monitor the packing process in real-time.

Section 3: Case Study: DEBAO-L666 Automatic Paper Cup Packing Machine

To illustrate the effectiveness of the Automatic Paper Packing Machine, let's dive into a case study. A customer factory recently implemented the DEBAO-L666 Automatic Paper Cup Packing Machine, and the results were remarkable. The machine seamlessly integrated into their existing production line and significantly improved efficiency. By automating the packing process, the factory experienced a reduction in labor costs and an increase in overall productivity. Moreover, the precise cup counting and stacking capabilities of the machine ensured consistent packaging quality, enhancing customer satisfaction.

Section 4: Advantages of the Automatic Paper Packing Machine

The Automatic Paper Packing Machine offers several advantages that make it an invaluable asset in the paper cup production industry. Firstly, it eliminates the need for manual packaging, saving time and reducing labor costs. Secondly, its precise cup counting and stacking features ensure consistent packaging quality, minimizing the risk of damaged or miscounted cups. Additionally, the machine's user-friendly interface and real-time monitoring capabilities enhance operational efficiency and facilitate easy troubleshooting.

Section 5: Future of Paper Cup Production and Packaging

As technology continues to evolve, the paper cup production industry is set to witness further advancements in automation and efficiency. The Automatic Paper Packing Machine exemplifies this trend and serves as a stepping stone towards a more streamlined and sustainable future. By embracing innovative solutions like this, manufacturers can stay ahead of the competition and cater to the ever-growing demand for paper cups.

Conclusion:

The Automatic Paper Packing Machine is a game-changer in the paper cup production industry. Its advanced features and automation capabilities significantly enhance efficiency and quality. The case study of its successful implementation in a customer factory is a testament to its effectiveness. As the industry continues to evolve, embracing such cutting-edge technology will undoubtedly lead to higher productivity and customer satisfaction. Check out the leading manufacturer for the professional coil packing solution right here. Paper Packing Machine

"Efficient Paper Cup Packing Machine: Witness the Seamless Automation in Customer Factory!"