Plastic injection molding is a widely used method for producing parts made of plastic material. In this article, we will explore the fundamentals of plastic injection molding and its association with industrial plastic injection machines. Join us as we delve into the world of plastic injection molding and discover why it is the go-to method for manufacturing plastic parts.

Introduction to Plastic Injection Molding

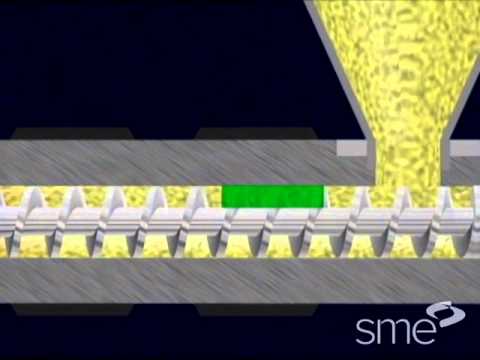

Plastic injection molding is a manufacturing process that involves injecting molten plastic material into a mold cavity. The plastic material is melted and injected under high pressure, conforming to the shape of the mold. Once the plastic has cooled and solidified, the mold is opened, and the finished part is ejected.

This method offers several advantages over other manufacturing processes. It allows for the production of complex and intricate parts with high precision and consistency. Additionally, plastic injection molding offers cost-effective mass production capabilities, making it suitable for various industries such as automotive, consumer goods, medical devices, and more.

The Role of Industrial Plastic Injection Machines

Industrial plastic injection machines play a crucial role in the plastic injection molding process. These machines are designed to handle the high pressures and temperatures necessary for melting and injecting plastic material into molds.

An industrial plastic injection machine consists of several components, including a hopper, an injection unit, and a clamping unit. The hopper stores the plastic material, which is fed into the injection unit. Within the injection unit, the plastic material is heated and melted. The molten plastic is then injected into the mold cavity through a nozzle and runner system.

The clamping unit of the machine ensures that the mold remains securely closed during the injection process. It applies the necessary force to keep the mold halves together and withstand the high injection pressures. The clamping unit also controls the mold opening and closing, allowing for the removal of the finished part.

Industrial plastic injection machines are available in various sizes and configurations, catering to different production requirements. Manufacturers can choose from hydraulic, electric, or hybrid machines, depending on their specific needs and preferences.

Benefits of Industrial Plastic Injection Machines

Industrial plastic injection machines offer numerous benefits that contribute to the success of the plastic injection molding process. These machines provide precise control over the injection parameters, resulting in consistent part quality. They also offer high production efficiency, allowing for rapid cycle times and increased output.

Furthermore, industrial plastic injection machines are equipped with advanced technologies and features that enhance productivity and reduce downtime. These include automated processes, real-time monitoring systems, and intuitive user interfaces. Such advancements enable manufacturers to optimize their production processes and ensure a smooth and efficient operation.

Conclusion

Plastic injection molding, coupled with industrial plastic injection machines, revolutionizes the manufacturing industry by providing a reliable and efficient method for producing plastic parts. Its versatility, precision, and cost-effectiveness make it an ideal choice for a wide range of applications.

Whether you are in the automotive, consumer goods, or medical device industry, understanding the fundamentals of plastic injection molding and the role of industrial plastic injection machines is essential. By harnessing the power of this technology, manufacturers can achieve high-quality parts, streamline their production processes, and stay competitive in the market.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant CTA] Plastic Injection Machine

"Efficient and Precise Plastic Injection Molding Techniques Explained: Enhancing Industrial Processes with Injection Machines"