Welcome to our YouTube video on the Automatic Plastic Injection Machine. In this video, we will explore how this device works and discuss all the components used. We will demonstrate how easily you can operate this machine and achieve the lowest production costs. Whether you are a professional or a DIY enthusiast, this video will provide you with valuable insights into the world of plastic injection molding.

Before we dive into the specifics, let's briefly talk about the history of plastic injection molding machines. These machines have revolutionized the manufacturing industry by allowing for efficient and precise production of plastic parts. Over the years, advancements in technology have led to the development of all-electric plastic injection molding machines, which offer numerous advantages over their hydraulic counterparts.

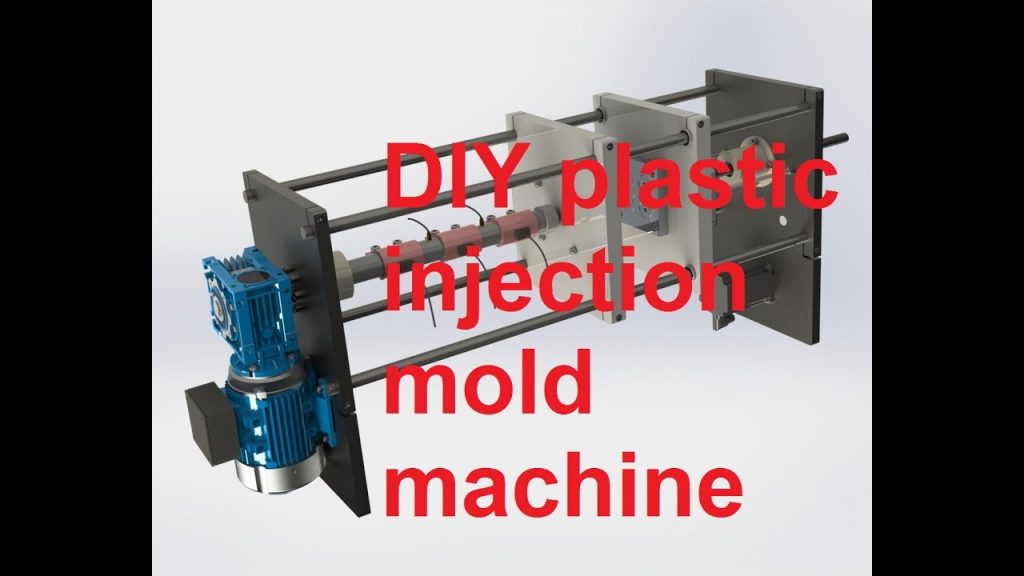

Now, let's explore how the Automatic Plastic Injection Machine functions. At its core, this machine utilizes a process called injection molding, where molten plastic is injected into a mold cavity to create a desired shape. The machine consists of several key components, including the injection unit, the clamping unit, the mold, and the control system.

The injection unit is responsible for melting and injecting the plastic into the mold. It consists of a hopper, where the plastic material is fed, and a screw or plunger, which melts and pushes the plastic forward. The clamping unit, on the other hand, holds the mold in place and applies the necessary pressure during the injection process.

The mold plays a crucial role in determining the final shape of the plastic part. It consists of two halves, the core, and the cavity, which are designed to create the desired shape when closed together. The control system, equipped with advanced software, regulates and monitors the entire injection process, ensuring precision and consistency.

One of the key advantages of the Automatic Plastic Injection Machine is its automation capabilities. This machine allows for high-speed production with minimal human intervention, reducing labor costs and increasing efficiency. Additionally, its all-electric nature offers energy savings and a cleaner production process compared to hydraulic machines.

For those looking to venture into plastic injection molding as a DIY project, the Automatic Plastic Injection Machine provides a user-friendly experience. With its intuitive controls and comprehensive documentation, even beginners can easily operate this machine and achieve professional results.

In conclusion, the Automatic Plastic Injection Machine is a versatile and efficient tool for plastic injection molding. Whether you are a professional manufacturer or a DIY enthusiast, this machine offers a cost-effective solution for producing high-quality plastic parts. With its advanced features and automation capabilities, it streamlines the production process and ensures consistent results.

Check out our leading manufacturer for a professional solution to your coil packing needs. They offer a wide range of coil packing solutions that are tailored to your specific requirements. Don't miss out on this opportunity to enhance your packaging processes. Plastic Injection Machine

"Building an Efficient DIY All-Electric Plastic Injection Molding Machine: A Step-by-Step Guide to Automating the Process"