Title: Advanced Packaging Line Automation | Streamlined Isotope Packaging Process

Description:

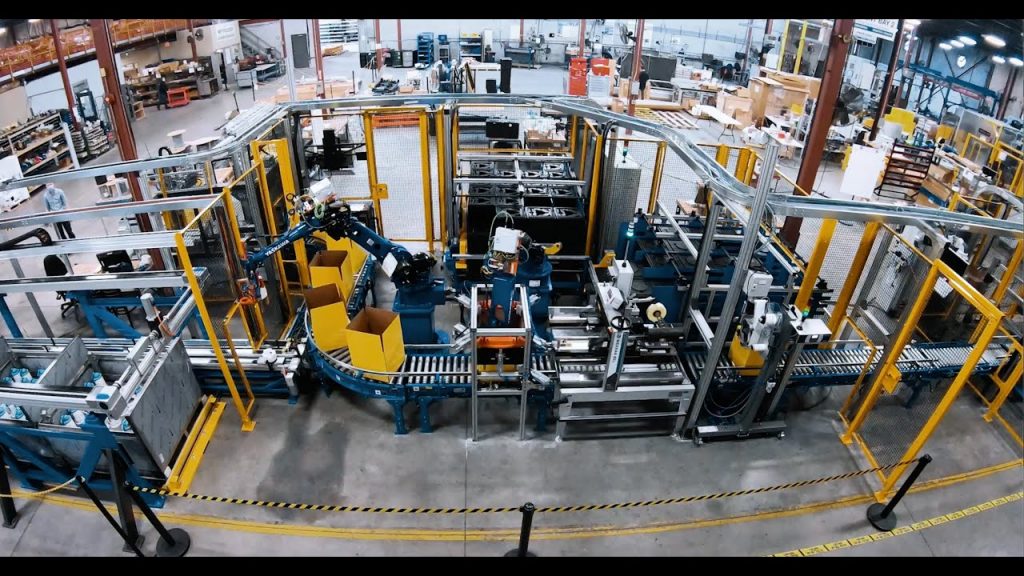

Welcome to our video showcasing the cutting-edge technology of Packaging Line Automation and the seamless process of Automated Isotope Packaging. In this video, we delve into the world of advanced packaging systems and the benefits they bring to the industry. Join us as we explore the intricacies of this automated solution, highlighting its features, operation steps, and key takeaways.

Introduction:

In this video, we bring you a comprehensive overview of Packaging Line Automation and its application in the automated packaging of isotopes. This revolutionary technology has transformed the way packaging is done, ensuring efficiency, accuracy, and optimal safety. Whether you are a professional in the field or simply curious about the advancements in packaging, this video is a must-watch.

Video Content:

1. Understanding Packaging Line Automation: Get a thorough understanding of the concept of packaging line automation, the role it plays in various industries, and its significance in improving productivity and reducing errors.

2. Benefits of Automated Isotope Packaging: Discover the advantages of using automated systems for packaging isotopes. From precise measurements to enhanced safety features, we highlight how this technology revolutionizes the packaging process.

3. Streamlined Operation Steps: Explore the step-by-step process of the automated isotope packaging line. We break down each stage, providing insights into the advanced machinery and robotics involved, ensuring a seamless and efficient packaging process.

4. Key Highlights and Interesting Facts: Delve deeper into the fascinating world of packaging line automation and automated isotope packaging. Uncover interesting facts and key highlights that make this technology stand out in the industry.

Call to Action:

If you found this video informative and engaging, we invite you to hit the like button and subscribe to our channel for more insightful content. Don't forget to share this video with your colleagues and friends who might find it valuable in their line of work.

Additional Tags and Keywords:

Packaging Line Automation, Automated Isotope Packaging, Packaging Systems, Advanced Packaging Technology, Robotics in Packaging, Efficiency in Packaging, Isotope Packaging Solutions, Automated Packaging Process, Streamlined Packaging Line

Hashtags:

#PackagingLineAutomation #AutomatedIsotopePackaging #AdvancedPackagingTechnology #EfficientPackaging #StreamlinedPackaging

Sure! Here's a sample tilter for an Automated Isotope Packaging Line:

Title: Automated Isotope Packaging Line Tilter

Objective: The objective of this tilter is to efficiently and accurately tilt containers of isotopes to facilitate their packaging in an automated isotope packaging line.

Requirements:

1. The tilter should be able to handle a variety of container sizes and shapes commonly used for isotope packaging.

2. The tilter should have a programmable tilt angle adjustment feature to accommodate different packaging requirements.

3. The tilter should have a high level of precision and accuracy to ensure proper positioning and alignment of the containers.

4. The tilter should be capable of handling fragile containers without causing any damage or leakage.

5. The tilter should have a user-friendly interface for easy operation and monitoring.

Components:

1. Tilt mechanism: The tilter should have a robust and reliable tilt mechanism, such as a motorized platform or conveyor belt, to smoothly and safely tilt the containers.

2. Adjustable tilt angle feature: The tilter should be equipped with a programmable control system that allows operators to adjust the tilt angle according to specific packaging requirements.

3. Sensors and detection systems: The tilter should be integrated with sensors and detection systems to ensure proper container positioning and alignment during the tilting process.

4. Safety features: The tilter should include safety features like emergency stop buttons, safety barriers, and interlocks to prevent accidents or injuries.

5. Control panel: The tilter should have a control panel with a user-friendly interface for operators to set tilt angles, monitor the tilting process, and troubleshoot any issues.

Procedure:

1. Place the containers on the tilter's platform or conveyor belt.

2. Set the desired tilt angle using the control panel.

3. Initiate the tilting process through the control panel or by activating a start button.

4. The tilter's mechanism will smoothly tilt the containers to the programmed angle.

5. Sensors and detection systems will ensure the containers are properly positioned and aligned during the tilting process.

6. Once the containers are tilted to the desired angle, they can be further processed in the automated isotope packaging line.

Note: This is just a general outline of a tilter for an Automated Isotope Packaging Line. The actual design and implementation may vary based on specific requirements and constraints. Automatic Packing Line

#Automated #isotope #packaging #line