Check out our video on how industrial and collaborative robots are revolutionizing the manufacturing industry! In this article, we will explore the unprecedented rate at which these robots are taking over manufacturing and discuss the key players in the industry.

Industrial and collaborative robots have become increasingly prevalent in manufacturing processes, thanks to their ability to enhance efficiency and productivity. The International Federation of Robotics (IFR) has reported a significant increase in the sales of industrial robots, highlighting the growing demand for these advanced automation systems.

With the rise of Industry 4.0 and the increasing need for flexible and adaptable production lines, industrial robot manufacturers have been at the forefront of developing cutting-edge solutions. These robots are designed to perform repetitive tasks with precision and speed, reducing human error and increasing overall productivity.

Collaborative robots, also known as cobots, have gained popularity due to their ability to work alongside human workers safely. They are equipped with advanced sensors and safety features to ensure a harmonious collaboration between humans and robots. Collaborative robots are particularly useful in tasks that require human dexterity and decision-making skills, such as assembly and quality control.

One of the leading industrial robot manufacturers in the market is ABB. They offer a wide range of robots designed for various applications, including welding, material handling, and assembly. ABB's robots are known for their high performance, reliability, and ease of use, making them a popular choice among manufacturers.

Another prominent player in the industry is Fanuc. Fanuc robots are highly versatile and can be easily integrated into existing manufacturing systems. Their robots are known for their precision and speed, making them ideal for applications that require high levels of accuracy.

In the realm of collaborative robots, Universal Robots is a key player. Their robots are known for their user-friendly interface and easy programming capabilities. Universal Robots' cobots are designed to work alongside humans, enhancing productivity and safety in manufacturing environments.

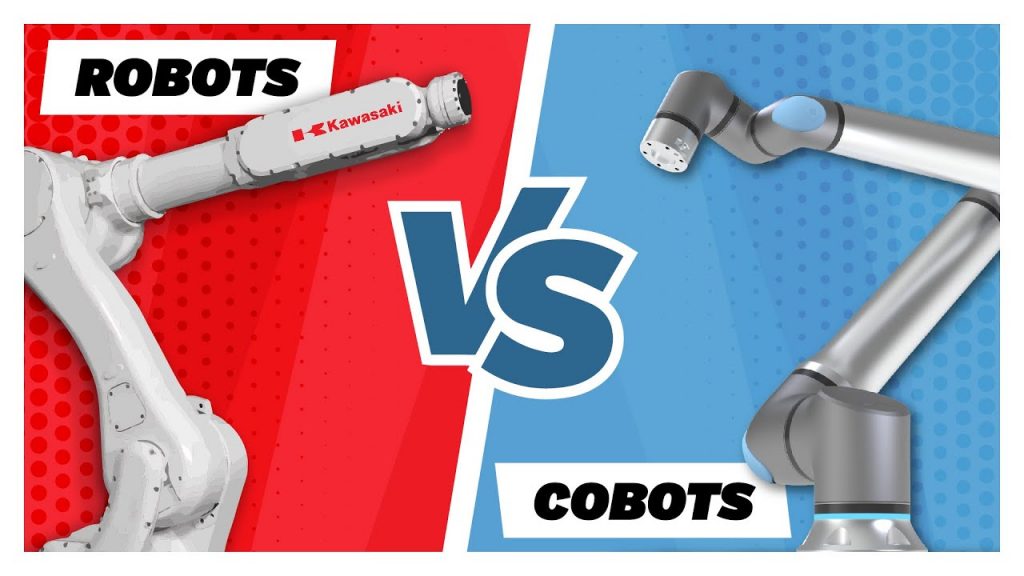

While industrial robots and collaborative robots both have their strengths, it is important to understand the specific needs and requirements of your manufacturing process before making a decision. Industrial robots excel in tasks that require speed and precision, while collaborative robots are better suited for tasks that require human interaction and flexibility.

In conclusion, industrial and collaborative robots are indeed taking over the manufacturing industry at an unprecedented rate. The advancements in technology and the increasing demand for automation have propelled these robots to the forefront of manufacturing processes. As a customer, it is essential to explore the offerings of leading industrial robot manufacturers and evaluate which solution best fits your needs.

Check out the video to learn more about the exciting advancements in industrial and collaborative robots and how they can revolutionize your manufacturing processes!

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant link] Industrial Robot

"Decoding the Industrial Robots vs. Collaborative Robots Debate: Is There a Clear Victor? Unveiling the Leading Manufacturers!"