Check out the leading manufacturer for professional coil packing solutions here:

If you are in the paper packaging industry, you understand the importance of efficiency and quality in your production process. One key aspect of this process is the creasing, gluing, and handle pasting of paper bags. To streamline these operations, many manufacturers are turning to automatic creasing, gluing machines, handle pasting machines, and bottom V creasing machines. In this article, we will explore the benefits of these machines and their role in the paper packaging industry.

Automatic creasing machines are designed to create precise creases on paper bags, ensuring a clean and professional finish. These machines use advanced technology to accurately fold the paper at the desired angles, resulting in consistent and high-quality creases. By automating this process, manufacturers can save time and reduce the risk of human error, leading to increased productivity and customer satisfaction.

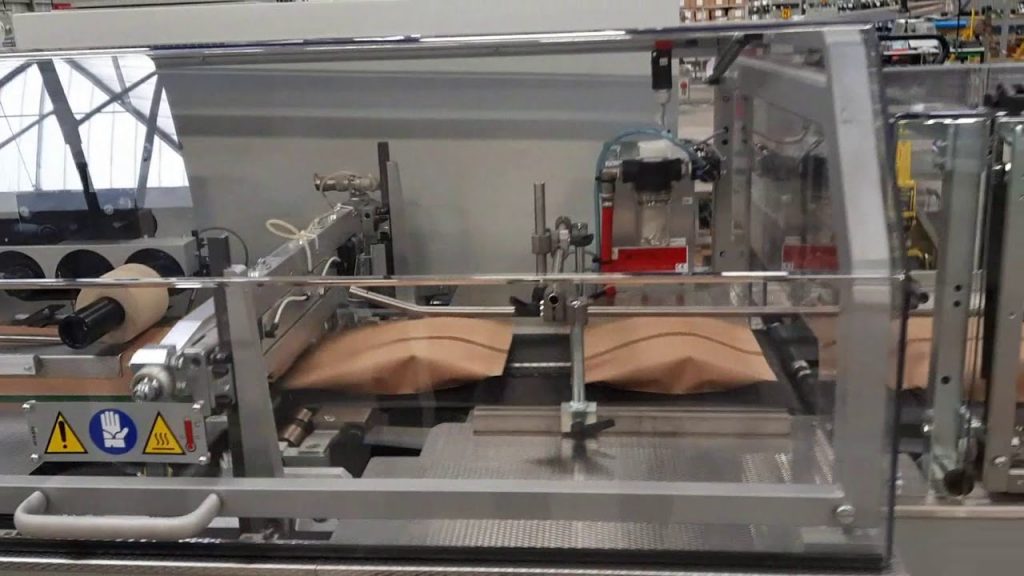

Gluing machines, on the other hand, are essential for securely sealing paper bags. These machines apply adhesive to the edges of the bags, ensuring they stay closed during transportation and use. With automatic gluing machines, manufacturers can achieve a consistent and uniform application of adhesive, improving the overall quality and durability of their paper bags. Additionally, these machines can handle various types of adhesives, allowing manufacturers to customize their gluing process based on their specific needs.

Handle pasting machines are specifically designed for attaching handles to paper bags. These machines automate the process of applying and securing handles, ensuring a strong and reliable attachment. By using handle pasting machines, manufacturers can significantly speed up their production process, reducing labor costs and increasing output. Moreover, these machines can handle different types of handles, such as rope handles or die-cut handles, providing versatility and flexibility to manufacturers.

Lastly, the bottom V creasing machine is an essential tool for creating the bottom structure of paper bags. This machine creates a V-shaped crease at the bottom of the bag, allowing for easy folding and assembly. With automatic bottom V creasing machines, manufacturers can ensure consistent and accurate creases, resulting in sturdy and well-structured paper bags. These machines are designed to handle various bag sizes and can be easily adjusted to meet specific customer requirements.

In conclusion, automatic creasing, gluing machines, handle pasting machines, and bottom V creasing machines play a vital role in the paper packaging industry. These machines offer numerous benefits, including increased efficiency, improved quality, and reduced labor costs. By investing in these advanced technologies, paper packaging manufacturers can enhance their production process and deliver high-quality products to their customers.

Check out the leading manufacturer for professional coil packing solutions here: [Insert manufacturer's website or contact information] Paper Packing Machine

"Efficient and Versatile Paper Bag and Packing Machines for Manufacturers"