If you're looking for a reliable and efficient way to produce plastic products, then an Automatic Plastic Injection Machine is the answer. In this YouTube video, we will take a closer look at the features and benefits of this machine, specifically focusing on the wire clip mode full automatic vertical plastic moulding machine weighing 100 grams.

Opinion/Thought Piece Style:

The world of manufacturing is constantly evolving, with new technologies and innovations emerging every day. One such innovation is the Automatic Plastic Injection Machine. This machine has revolutionized the way plastic products are produced, making the process faster, more efficient, and more cost-effective.

Gone are the days of manually injecting plastic into molds. With the Automatic Plastic Injection Machine, the entire process is automated, from the injection of the plastic to the ejection of the finished product. This not only saves time but also ensures consistency in the quality of the products being produced.

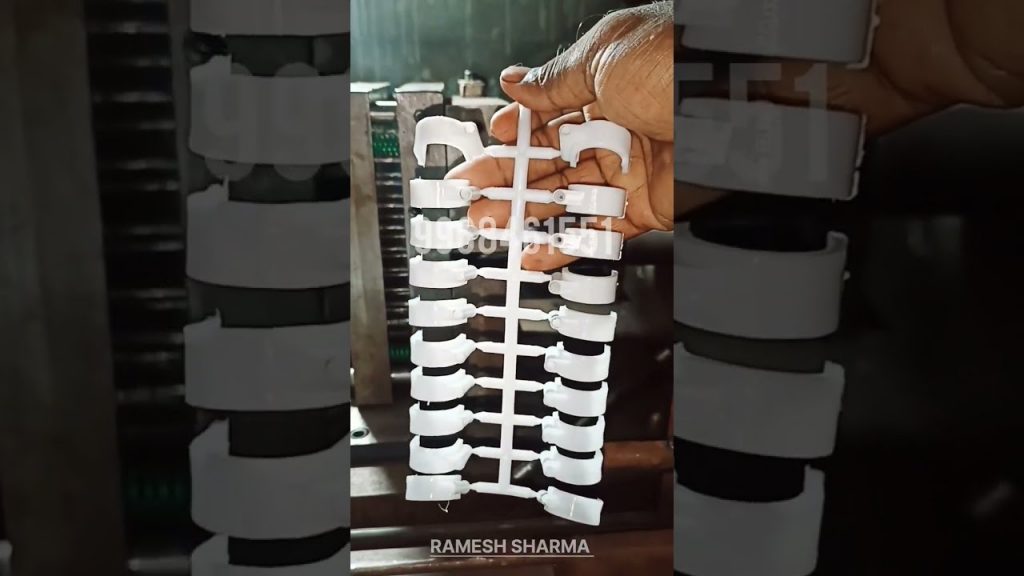

One of the key features of the Automatic Plastic Injection Machine is its wire clip mode. This mode allows for the production of plastic products that weigh 100 grams, making it ideal for a wide range of applications. Whether you need to produce small plastic components or larger parts, this machine has got you covered.

The vertical design of the machine also offers several advantages. It takes up less floor space compared to horizontal machines, making it a great option for factories with limited space. Additionally, the vertical design allows for easier access to the molds, making maintenance and troubleshooting a breeze.

Interview Style:

In an exclusive interview with our sales engineer, we gained valuable insights into the Automatic Plastic Injection Machine and its wire clip mode full automatic vertical plastic moulding machine weighing 100 grams. According to our expert, this machine is in high demand due to its efficiency and versatility.

"The Automatic Plastic Injection Machine is a game-changer in the manufacturing industry," said our sales engineer. "It not only speeds up the production process but also ensures consistent quality."

When asked about the wire clip mode, our expert explained, "This mode is perfect for producing plastic products weighing 100 grams. It opens up a world of possibilities for manufacturers, as they can now easily produce a wide range of components."

Case Study Style:

One of the success stories of the Automatic Plastic Injection Machine comes from a factory in Bihar. This factory was struggling to keep up with the demand for their plastic products, as their manual injection process was slow and unreliable. However, after investing in the Automatic Plastic Injection Machine, their production rate increased significantly.

"The Automatic Plastic Injection Machine has been a game-changer for our factory," said the factory manager. "We are now able to produce more products in less time, without compromising on quality."

The wire clip mode of the machine has also been a game-changer for this factory. They are now able to produce a variety of plastic components weighing 100 grams, meeting the diverse needs of their customers.

Explanatory Style:

The Automatic Plastic Injection Machine is a state-of-the-art machine that automates the entire plastic injection process. It works by melting plastic pellets and injecting them into molds to create various plastic products. The wire clip mode is a specific feature of this machine that allows for the production of plastic products weighing 100 grams.

The vertical design of the machine offers several advantages. It takes up less space, making it suitable for factories with limited floor space. The vertical design also allows for easier access to the molds, simplifying maintenance and troubleshooting.

In-depth Analysis Style:

The Automatic Plastic Injection Machine has revolutionized the manufacturing industry by automating the plastic injection process. This machine offers a range of benefits, including increased production speed, consistent product quality, and cost savings.

The wire clip mode of the machine has opened up new opportunities for manufacturers. With the ability to produce plastic products weighing 100 grams, manufacturers can now cater to a wider range of customer needs. This mode is particularly useful for producing small plastic components or larger parts.

In conclusion, the Automatic Plastic Injection Machine is a game-changer in the manufacturing industry. Its wire clip mode and vertical design make it a versatile and efficient solution for producing high-quality plastic products. Check out the video to see this machine in action and witness its capabilities firsthand.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [URL] Plastic Injection Machine

"Efficient Vertical Plastic Moulding Machine for Bihar's Hardware Industry"