Are you interested in learning about the latest advancements in industrial robotics? Look no further! In this YouTube video, we will explore how Universal Robots has revolutionized the field of robotics with their innovative lightweight and flexible robot arms known as Cobots, or collaborative robots. These Cobots have opened up new possibilities for Industrial Robot Applications, making them a game-changer in various industries.

[Opinion/Thought Piece Style]

The introduction of Universal Robots' Cobots has truly transformed the world of industrial robotics. With their lightweight and flexible design, these robot arms have redefined the way we think about automation in manufacturing. Industrial Robot Applications have never been more accessible and adaptable than with these collaborative robots.

[Case Study Style]

Let's take a closer look at some real-life examples of Industrial Robot Applications made possible by Universal Robots' Cobots. In the automotive industry, these Cobots have been utilized for tasks such as assembly line operations, welding, and even painting. Their ability to work alongside human operators in a collaborative manner has increased productivity and efficiency while ensuring a safe working environment.

In the electronics industry, Cobots have revolutionized the production process by streamlining tasks like pick-and-place operations, quality control, and packaging. The lightweight nature of these robot arms allows for easy integration into existing workflows, making them a cost-effective solution for manufacturers.

[Predictive/Foresight Style]

The future of Industrial Robot Applications looks promising with Universal Robots' Cobots leading the way. As technology continues to evolve, we can expect to see even more advancements in the capabilities of these collaborative robots. With the rise of artificial intelligence and machine learning, Cobots will become more intelligent and autonomous, further enhancing their efficiency and adaptability in various industries.

[Explanatory Style]

To understand the impact of Universal Robots' Cobots on Industrial Robot Applications, it is crucial to delve into their features and capabilities. These robot arms are designed to be lightweight and easily programmable, allowing for quick deployment and reconfiguration. Their flexibility enables them to perform a wide range of tasks, from simple pick-and-place operations to complex assembly processes.

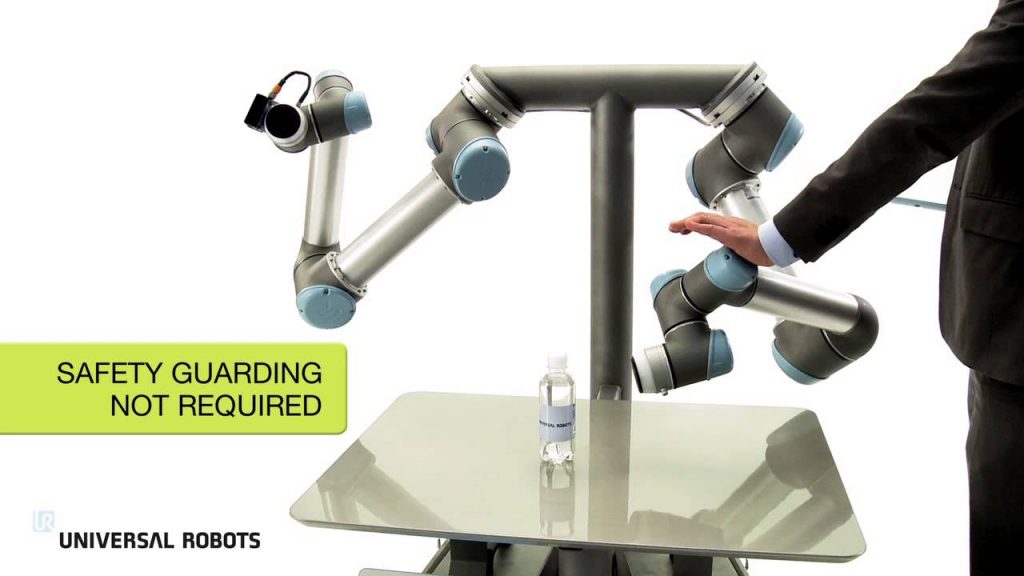

Cobots are also equipped with advanced safety features, such as force sensors and collision detection, ensuring the well-being of human operators working alongside them. This collaborative nature not only enhances productivity but also opens up opportunities for human-robot collaboration in tasks that require precision and efficiency.

[In-depth Analysis Style]

The introduction of Cobots by Universal Robots has disrupted the traditional perception of industrial robotics. In the past, industrial robots were often large and cumbersome, requiring extensive programming and safety measures. However, with the advent of Cobots, a new era of automation has emerged.

These lightweight and flexible robot arms have made Industrial Robot Applications more accessible to small and medium-sized enterprises (SMEs). The ease of programming and integration into existing workflows has reduced the barriers to entry for automation, allowing SMEs to compete on a global scale.

[How-to Guide Style]

Are you considering integrating Universal Robots' Cobots into your manufacturing processes? Here are some steps to follow for a successful implementation:

1. Identify the tasks that can be automated: Analyze your production processes and identify tasks that can be efficiently handled by Cobots. Look for repetitive, mundane, or hazardous tasks that can be automated to improve productivity and safety.

2. Assess the workspace and safety requirements: Ensure that your workspace is suitable for the deployment of Cobots. Conduct a risk assessment to identify potential hazards and implement necessary safety measures.

3. Choose the right Cobot model: Universal Robots offers a range of Cobots with different payload capacities and reach. Select the model that best suits your specific Industrial Robot Applications.

4. Program and configure the Cobot: Universal Robots' Cobots are designed to be easily programmed even by non-experts. Utilize the intuitive software interface to set up the desired tasks and workflows.

5. Train your employees: Provide training to your employees on working with Cobots and ensure they understand the safety protocols and guidelines for collaborative operations.

By following these steps, you can successfully integrate Cobots into your manufacturing processes and reap the benefits of increased productivity, efficiency, and safety.

[Check the coil packing solution with the leading manufacturer for a professional solution right here:] Industrial Robot

"Revolutionizing Industrial Automation: Discover the Power of Cobots and Advanced Industrial Robot Applications"