If you're interested in learning about collaborative robotics and the safety measures that go along with it, you've come to the right place. In this tutorial video, we will be exploring the Tampere University course on collaborative robotics and specifically focusing on the kinetic energy of a 225kg heavy payload. We will also delve into the importance of industrial robot safety and how it relates to heavy industrial robot collisions.

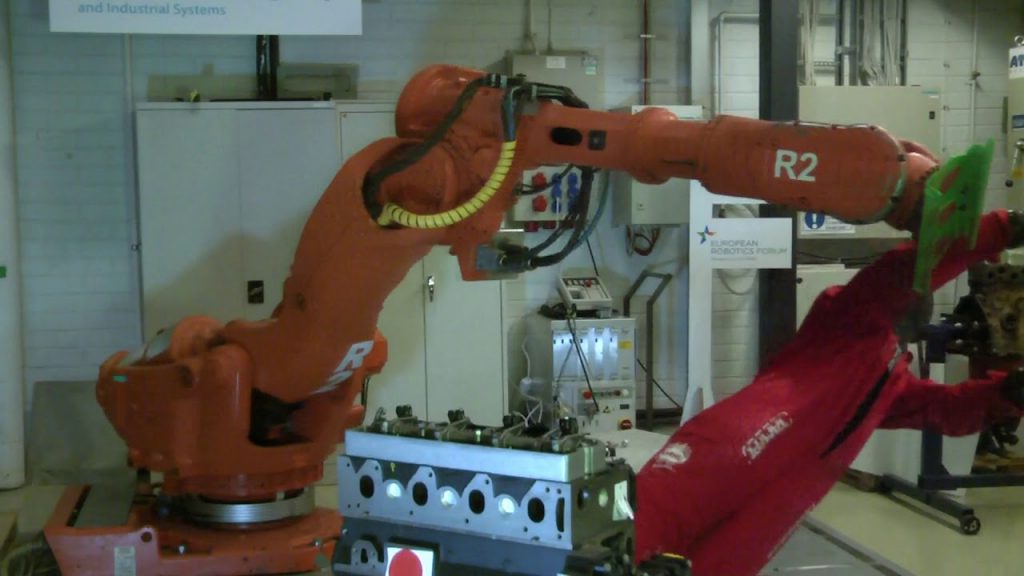

Before we dive into the specifics, let's first discuss the concept of collaborative robotics. Collaborative robotics, also known as cobots, refers to the interaction between humans and robots in a shared workspace. Unlike traditional industrial robots that are designed to work autonomously, cobots are specifically designed to work alongside humans, assisting them in various tasks.

Now, let's talk about the Tampere University course on collaborative robotics. This course offers a comprehensive understanding of the field, covering topics such as robot kinematics, dynamics, control, perception, and human-robot interaction. It provides students with hands-on experience in programming, controlling, and operating collaborative robots.

One of the key aspects that this video tutorial focuses on is the kinetic energy of a 225kg heavy payload. Kinetic energy can be defined as the energy possessed by an object due to its motion. In the context of industrial robotics, understanding the kinetic energy of a heavy payload is crucial for ensuring the safety of both humans and the robots themselves. By analyzing the kinetic energy, engineers and operators can implement appropriate safety measures to prevent collisions and accidents.

Speaking of safety, industrial robot safety is of utmost importance in any industrial setting. With the increasing use of collaborative robots, it becomes even more critical to prioritize safety measures. Industrial robots are incredibly powerful and can cause significant damage if proper safety precautions are not taken. This is why thorough risk assessments, safety training, and the implementation of safety systems are essential.

When it comes to heavy industrial robot collisions, the consequences can be severe. These collisions can result in damage to the robot, the payload, and even pose a significant risk to human operators. Therefore, it is vital to have a thorough understanding of industrial robot safety measures to prevent such collisions from occurring.

In conclusion, this tutorial video on the Tampere University course in collaborative robotics provides valuable insights into the kinetic energy of a 225kg heavy payload and its relation to industrial robot safety. By understanding and implementing proper safety measures, we can ensure the well-being of both humans and robots in industrial settings.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [insert URL] Industrial Robot

"Ensuring Safety in Heavy Industrial Robot Environments: Preventing Collisions and Promoting Industrial Robot Safety"