Check out the leading manufacturers for professional coil packing solutions right here:

Collaborative robots, also known as cobots, have revolutionized the manufacturing industry by seamlessly integrating with human workers to enhance productivity and efficiency. One perfect example of this collaboration can be witnessed at Baxter Laboratories in their end-of-line packing process.

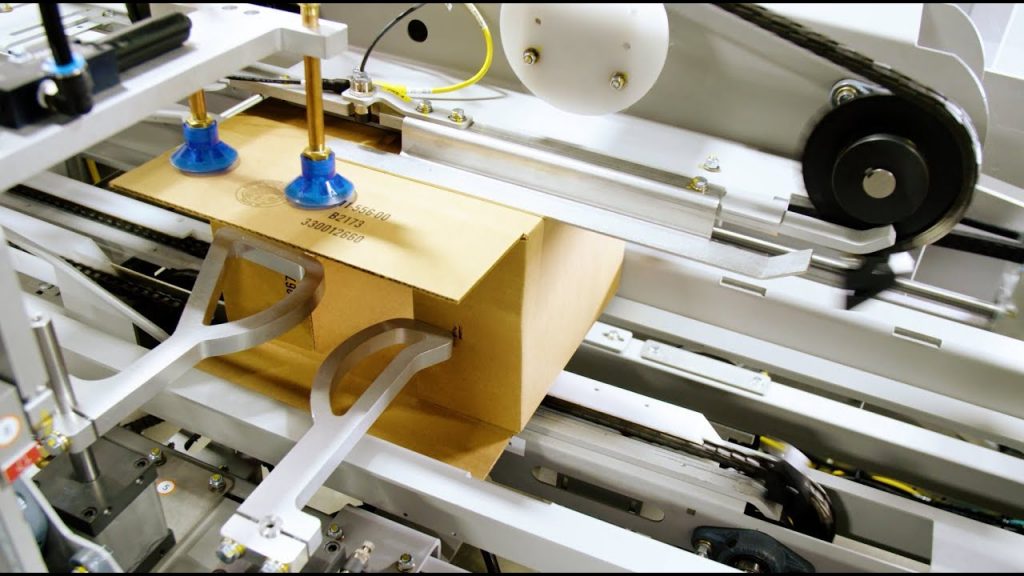

In this end-of-line packing process, Baxter Laboratories has adopted state-of-the-art technology in the form of case packing machines. These machines are designed to automate the packing of products into cases, ensuring accuracy and speed in the packaging process. By implementing these machines, Baxter Laboratories has not only increased their production capacity but also improved the overall quality of their products.

Case packing machine manufacturers play a crucial role in providing the advanced technology required for seamless collaboration between robots and humans. These manufacturers understand the specific needs of industries like Baxter Laboratories and strive to deliver cutting-edge solutions tailored to their requirements.

The collaborative efforts between robots and humans at Baxter Laboratories have resulted in numerous benefits. Firstly, the precision and accuracy provided by the case packing machines ensure that products are packaged correctly, reducing the risk of errors and minimizing waste. This not only saves time but also enhances customer satisfaction.

Secondly, the integration of robots in the packing process has significantly increased the speed and efficiency of operations. By automating repetitive tasks, robots allow human workers to focus on more complex and value-added activities. This synergy between automation and human intelligence leads to higher productivity and improved overall efficiency.

The collaborative nature of cobots in the packing process has also improved workplace safety. These robots are designed to work alongside humans without endangering their well-being. By taking over heavy lifting and repetitive tasks, cobots reduce the risk of strain injuries and accidents, creating a safer and more ergonomic work environment for employees.

Baxter Laboratories recognizes the importance of choosing the right case packing machine manufacturers to ensure a seamless integration of robots and humans in their packing process. By collaborating with leading manufacturers, they have been able to optimize their operations and achieve exceptional results.

If you are in search of reliable case packing machine manufacturers, look no further. These manufacturers offer a wide range of solutions tailored to meet your specific needs. From high-speed case packers to versatile palletizing systems, they have the expertise and technology to enhance your packaging process.

In conclusion, the collaborative efforts between robots and humans at Baxter Laboratories exemplify the possibilities and benefits of integrating cobots in the manufacturing industry. By adopting advanced case packing machines from leading manufacturers, they have improved productivity, efficiency, accuracy, and workplace safety. If you are looking for professional coil packing solutions, make sure to check out the leading manufacturers in the industry. They can provide you with the perfect solution to optimize your packing process.

Check out the leading manufacturers for professional coil packing solutions right here. Case Packing Machine

"Efficient Case Packing and Palletising Solutions: Enhancing Productivity in the Manufacturing Industry"