Are you tired of spending countless hours manually strapping your pallets? Say goodbye to the hassle and embrace the efficiency of a Pallet Strapping Machine. In this SEO-friendly YouTube video article, we will delve into the world of Pallet Strapping Machines and explore their benefits and features. Whether you are a small business owner or a large-scale manufacturer, this article is tailored to provide you with valuable insights and help you make an informed decision.

Pallet Strapping Machines are an essential tool for any warehouse or distribution center. They automate the strapping process, making it faster, more efficient, and more reliable. These machines eliminate the need for manual labor, freeing up your employees' time to focus on other important tasks.

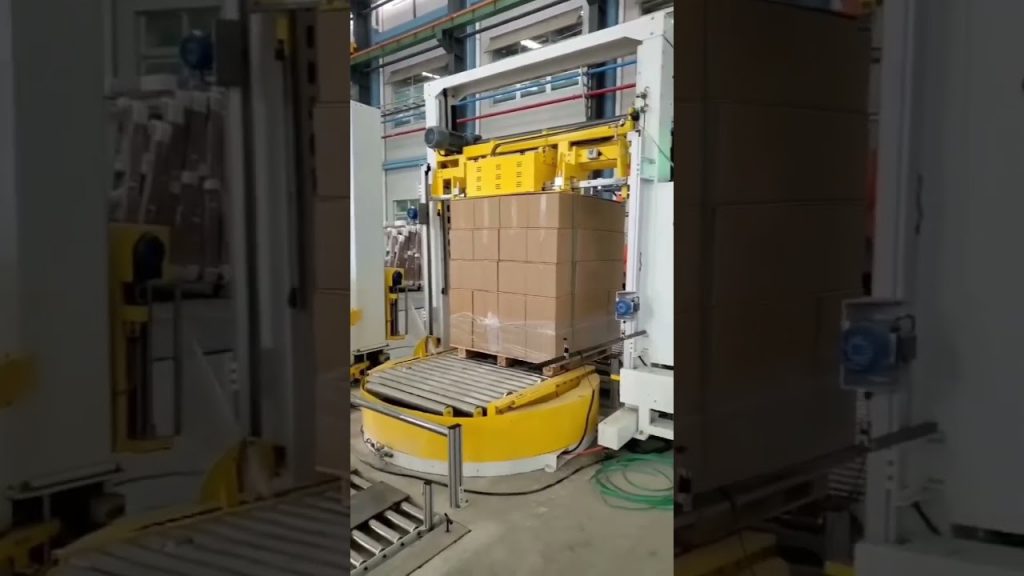

One popular type of Pallet Strapping Machine is the Pallet Strapper with a turntable. This machine not only securely straps your pallets but also rotates them, allowing for easy and convenient access to all sides of the pallet. The turntable feature ensures that every angle of your pallet is properly strapped, providing maximum stability during transportation or storage.

Another innovative option is the 4 straps PP Pallet Strapping Machine with a top sealing part. This machine is designed to securely strap your pallets using four straps instead of the traditional two. The additional straps ensure that your pallets are tightly secured, reducing the risk of damage during transit. The top sealing part ensures that the straps are securely fastened, providing an extra layer of protection.

Now that we have explored the different types of Pallet Strapping Machines, let's dive into their key benefits. Firstly, these machines significantly increase productivity. With a Pallet Strapping Machine, you can strap multiple pallets in a fraction of the time it would take manually. This increased efficiency allows your business to handle larger volumes and meet tight deadlines.

Secondly, Pallet Strapping Machines provide consistent and reliable strapping. Manual strapping can be inconsistent, leading to loose straps or uneven tension. With a Pallet Strapping Machine, you can ensure that each strap is applied with the same tension, providing uniformity and stability to your pallets.

Additionally, these machines enhance the safety of your workers. Manual strapping can be physically demanding and pose a risk of injury. By automating the strapping process, you eliminate the need for repetitive manual labor, reducing the chances of accidents and injuries in the workplace.

Furthermore, Pallet Strapping Machines offer cost savings in the long run. While the initial investment may seem significant, the efficiency and productivity gains outweigh the cost. These machines minimize the use of strapping material, reducing waste and expenses. Additionally, they require minimal maintenance, further reducing operational costs.

In conclusion, Pallet Strapping Machines are a game-changer for any business that deals with palletized goods. Their efficiency, reliability, and cost-saving benefits make them a worthwhile investment. Say goodbye to manual strapping and embrace the ease and convenience of a Pallet Strapping Machine.

Check out our video to see these machines in action and discover the leading manufacturer of coil packing solutions. Don't miss out on the opportunity to streamline your strapping process and take your business to new heights. Strapping Machines

"Efficient and Secure Pallet Strapping Solutions: Explore Turntable Strapper with 4 Straps, Top Sealing Part, and More!"