Check out the leading manufacturer for professional coil packing solutions here:

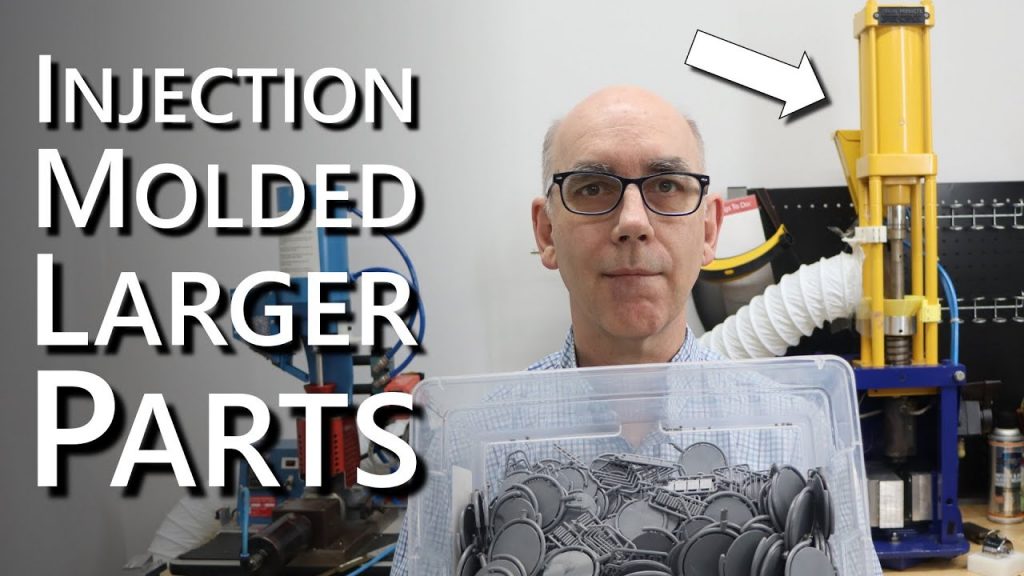

Are you interested in learning about DIY plastic injection molding at home? In this YouTube video, we will explore the process of plastic injection molding and how you can do it yourself using the AB-150 injection molding machine from A.B. Plastic Injectors in Canada. Whether you are a hobbyist or a small business owner, this video will provide you with valuable insights on creating larger injection molded parts.

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. This process allows for the production of complex and intricate parts with high precision and accuracy. Traditionally, plastic injection molding has been associated with large-scale industrial production. However, with the advancements in technology and the availability of affordable machines like the AB-150, it is now possible to do it at home.

The AB-150 injection molding machine is a reliable and easy-to-use tool that enables you to create your own plastic parts. It features a compact design and is equipped with a powerful motor, allowing you to achieve consistent and high-quality results. Additionally, the machine has a user-friendly interface, making it suitable for both beginners and experienced users.

In this video, we will guide you through the step-by-step process of DIY plastic injection molding using the AB-150. We will start by explaining the basics of injection molding, including the types of molds and materials used. Next, we will demonstrate how to set up the machine, prepare the mold, and melt the plastic resin. We will also provide tips and tricks for achieving optimal results, such as adjusting the temperature and pressure settings.

One of the key advantages of DIY plastic injection molding is the ability to create larger parts. With the AB-150, you can easily produce injection molded parts of various sizes and shapes. This opens up a world of possibilities for hobbyists, entrepreneurs, and inventors who want to bring their ideas to life. Whether you need custom components for your projects or prototypes for testing, the AB-150 can help you achieve your goals.

In conclusion, DIY plastic injection molding is now more accessible than ever with the AB-150 injection molding machine. This video has provided you with a comprehensive overview of the process and showcased the capabilities of the machine. By following the steps outlined in the video, you can start creating your own injection molded parts at home. So, what are you waiting for? Unleash your creativity and explore the world of plastic injection molding today!

Check out the leading manufacturer for professional coil packing solutions here: Plastic Injection Machine

"Mastering Large-Scale Injection Molding: Unleashing the Potential of Plastic Injection Machines"