Title: Packaging Line Automation | Complete Solutions for Streamlined Packaging Processes

Description:

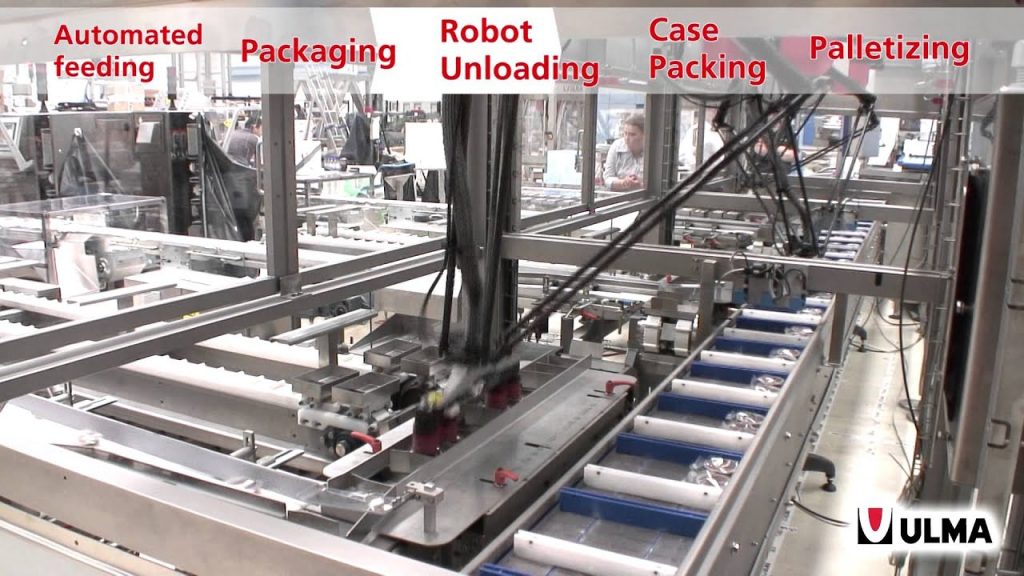

Welcome to our video on Packaging Line Automation! In this informative and engaging video, we dive deep into the world of packaging line automation, focusing on the comprehensive solutions offered by ULMA Packaging Automation (UPA). Whether you're a manufacturer, distributor, or packaging professional, this video will provide valuable insights and expert guidance on how to optimize your packaging processes.

Introduction:

In this video, we explore the cutting-edge technology and complete automation solutions provided by ULMA Packaging Automation (UPA). We delve into the benefits of incorporating packaging line automation into your operations and how it can revolutionize your packaging processes.

Video Content:

1. Understanding Packaging Line Automation:

- Learn about the concept of packaging line automation and its significance in enhancing productivity, efficiency, and cost-effectiveness.

- Discover how automated systems streamline the packaging process, ensuring consistent results and reducing human error.

2. Key Features and Solutions:

- Explore the complete and integral solutions offered by ULMA Packaging Automation (UPA) for automating packaging lines.

- Gain insights into the advanced technologies utilized, such as robotics, conveyor systems, and intelligent software integration.

3. Benefits of Packaging Line Automation:

- Uncover the numerous advantages of implementing packaging line automation, including increased throughput, improved product quality, and reduced labor costs.

- Understand how automation enhances overall safety measures and compliance with industry standards.

4. Operation Steps and Highlights:

- Get a step-by-step breakdown of how packaging line automation works, from product handling and sorting to labeling and packaging.

- Discover the highlights and key points to consider when integrating automation into your packaging line.

Call to Action:

If you found this video helpful and informative, please consider liking, subscribing, and sharing it with your colleagues and industry peers. Stay updated with the latest advancements in packaging line automation by subscribing to our channel.

Additional Tags and Keywords:

packaging line automation, automated packaging solutions, ULMA Packaging Automation, UPA, robotics in packaging, conveyor systems, intelligent software integration, packaging process optimization, increased productivity, cost-effective packaging, improved product quality, reduced labor costs, industry compliance.

Hashtags:

#PackagingLineAutomation #AutomatedPackagingSolutions #ULMAPackagingAutomation #PackagingProcessOptimization #ProductivityEnhancement #CostEffectivePackaging #IndustryCompliance

Title: Enhancing Efficiency and Accuracy in Packaging Line Automation

Introduction:

In today's fast-paced manufacturing environment, the demand for efficient and accurate packaging line automation is higher than ever before. With increased production volumes and stricter quality control requirements, it is essential to implement a robust tilter system that streamlines the packaging process while minimizing errors and downtime. This tilter aims to revolutionize the packaging industry by offering improved efficiency, precision, and reliability.

1. Streamlined Operation:

- The tilter ensures a seamless transition between different stages of the packaging line, reducing bottlenecks and optimizing overall efficiency.

- It minimizes manual handling, eliminating the risk of human error and enhancing worker safety.

- Integration with other automation systems, such as conveyors and robotic arms, enables a synchronized workflow, resulting in higher productivity.

2. Precise Orientation:

- The tilter ensures accurate positioning and orientation of products, allowing for consistent packaging and reducing the need for reworks.

- Advanced sensors and precision controls guarantee precise angles and rotations, resulting in properly aligned products that meet customers' specifications.

- Integration with computer vision technology enables real-time monitoring and adjustment, further enhancing accuracy.

3. Versatile Adaptability:

- The tilter is designed to accommodate various product shapes, sizes, and weights, making it adaptable to a wide range of packaging requirements.

- Adjustable tilting parameters allow for customization based on specific product characteristics, ensuring optimal positioning during the packaging process.

- Quick changeover capabilities enable seamless transitions between different product types, minimizing downtime and maximizing production output.

4. Reliable Performance:

- The tilter is built with robust materials and components, ensuring durability and longevity in demanding manufacturing environments.

- Regular maintenance and self-diagnostic features ensure uninterrupted operation, reducing the risk of unexpected breakdowns.

- Integration with a centralized control system provides real-time monitoring and proactive maintenance, maximizing uptime and minimizing costly disruptions.

5. Data-driven Optimization:

- The tilter incorporates data collection and analysis capabilities, providing valuable insights into production efficiency, product quality, and performance trends.

- Continuous monitoring of key performance indicators enables proactive decision-making and optimization of the packaging line.

- Integration with existing enterprise resource planning (ERP) systems allows for seamless data exchange and enhanced overall operational visibility.

Conclusion:

By implementing this advanced tilter system, packaging line automation is taken to new heights. Its streamlined operation, precise orientation, versatile adaptability, reliable performance, and data-driven optimization contribute to increased productivity, reduced errors, and improved customer satisfaction. Embracing this tilter technology is the key to achieving enhanced efficiency and accuracy in the packaging industry. Automatic Packing Line

#Packaging #line #automation