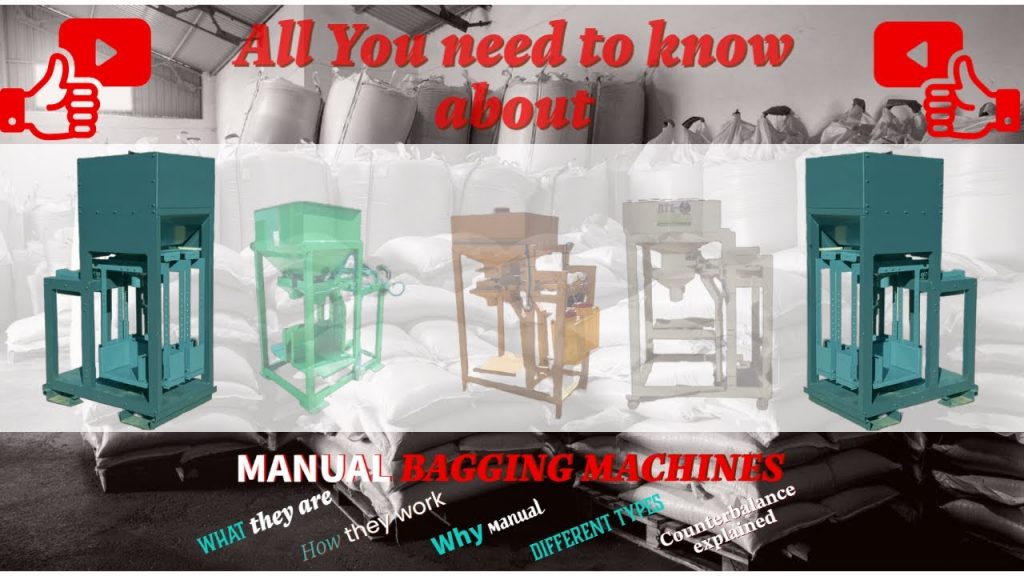

In this YouTube video, we will provide you with all the essential information about manual bagging machines. If you are in the market for a bagging machine, it's crucial to understand what manual baggers are and how they can benefit your business. We will also discuss the factors that impact the bagging machine price.

Manual baggers are versatile machines used to pack various products into bags manually. They are operated by an individual who fills the bags with the desired product, such as grains, seeds, powders, or small parts. These machines are widely used in industries like agriculture, food processing, chemicals, and hardware.

So, what makes manual bagging machines a popular choice for many businesses? One key advantage is their simplicity and ease of use. With minimal training, anyone can efficiently operate a manual bagger, making it a cost-effective solution for small-scale operations or businesses with limited budgets.

Additionally, manual bagging machines offer flexibility in terms of bag sizes and materials. You can use them with various bag types, such as paper, plastic, or woven bags, depending on your specific requirements. This versatility ensures that you can adapt the machine to your packaging needs without the need for expensive customization.

Now, let's talk about the factors that influence the bagging machine price. Several aspects contribute to the overall cost of a manual bagger. These include the machine's capacity, construction materials, additional features, and the brand reputation.

Higher-capacity machines generally come at a higher price point due to their ability to handle larger volumes of products. The construction materials used in the machine's design also impact the price. For instance, stainless steel machines are more durable and resistant to corrosion, but they may be more expensive than those made of other materials.

Additional features, such as digital controls, automatic bag feeding, and integrated weighing systems, can increase the bagging machine price. These features enhance efficiency and accuracy during the packaging process, which may be worth the investment depending on your specific needs.

Finally, the brand reputation plays a role in determining the cost of a bagging machine. Well-established and reputable manufacturers often offer higher-quality machines, which can result in a slightly higher price tag. However, investing in a reliable brand ensures better performance, longevity, and after-sales support.

In conclusion, manual bagging machines are versatile and cost-effective solutions for businesses in need of packaging products into bags. Understanding the various factors that influence the bagging machine price is crucial in making an informed decision for your business.

Check out the leading manufacturers in the industry for professional and reliable coil packing solutions. They can provide you with the right machine to meet your specific needs. Bagging Machine

"Ultimate Guide to Manual Bagging Machines: Everything You Should Know About Bagging Machine Price and Features"