Title: Ultimate Guide to Automatic Filling and Packing Machines | Curd Cup Filling Sealing Machine | Rotary Cup Filling Sealing Machine | Rabdi Cup Sealing Machine

Description:

Introduction:

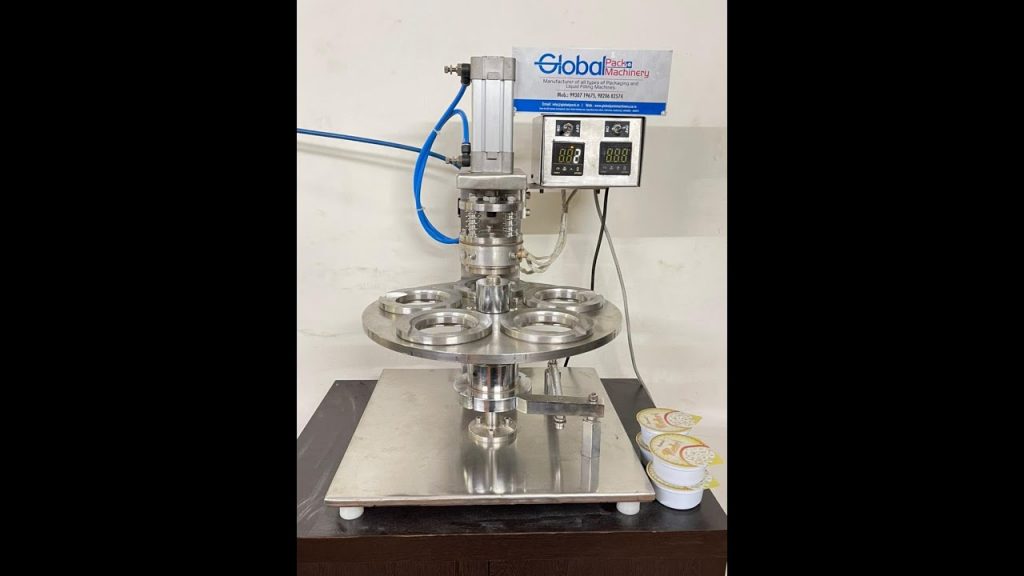

Welcome to our comprehensive guide on Automatic Filling and Packing Machines, specifically focusing on Curd Cup Filling Sealing Machines, Rotary Cup Filling Sealing Machines, and Rabdi Cup Sealing Machines. In this video, we will provide you with an in-depth overview of these machines, their functionalities, and the benefits they offer for efficient packaging processes.

Video Content:

In this video, we will cover everything you need to know about Automatic Filling and Packing Machines. We will discuss the various types of machines available such as Curd Cup Filling Sealing Machines, Rotary Cup Filling Sealing Machines, and Rabdi Cup Sealing Machines. These machines are also commonly referred to as Rotary Cup Filling Sealing Machines.

Key Features and Benefits:

- Precise Filling: Our Automatic Filling and Packing Machines ensure accurate and consistent filling of cups, guaranteeing the perfect portion every time.

- Efficient Sealing: With advanced sealing mechanisms, these machines provide a secure and airtight seal, extending the shelf life of the packaged products.

- Versatility: These machines are designed to handle a wide range of cup sizes and materials, allowing for flexibility in packaging different products.

- Easy Operation: Our machines are user-friendly and equipped with intuitive controls, making them easy to operate and maintain.

- Speed and Productivity: These machines are capable of high-speed filling and sealing, enhancing production efficiency and reducing labor costs.

Operation Steps:

1. Cup Loading: The cups are loaded onto the machine's conveyor belt.

2. Filling: The products are accurately dispensed into each cup using a precise filling mechanism.

3. Sealing: The cups are sealed using heat or pressure, ensuring a tight seal to prevent leakage or contamination.

4. Date Coding: Some machines come with an integrated date coding feature to imprint batch numbers or expiration dates on the cups.

5. Cup Discharge: The sealed cups are automatically discharged from the machine for further processing or packaging.

Call to Action:

If you found this video helpful in understanding the Automatic Filling and Packing Machines, please consider liking, subscribing, and sharing it with others who might benefit from this information. For more videos on packaging solutions and machine demonstrations, make sure to subscribe to our channel.

Additional Tags and Keywords:

Automatic Filling and Packing Machine, Curd Cup Filling Sealing Machine, Rotary Cup Filling Sealing Machine, Rabdi Cup Sealing Machine, Rotary Cup Filling Sealing Machine, Curd Cup Filling Sealing Machine, packaging machines, cup filling machines, cup sealing machines, efficient packaging, food packaging, production efficiency, user-friendly machines, packaging solutions, machine demonstrations.

Hashtags: #AutomaticFillingandPackingMachine #CurdCupFillingSealingMachine #RotaryCupFillingSealingMachine #RabdiCupSealingMachine #PackagingMachines #EfficientPackaging #FoodPackaging #ProductionEfficiency

A tilter for Curd Cup Filling Sealing Machine, Rotary Cup Filling Sealing Machine, and Rabdi Cup Sealing Machine can be designed and implemented to improve the efficiency and accuracy of the filling and sealing process. The tilter would be responsible for tilting the cups at a particular angle to ensure proper filling and sealing.

Here is a sample code for the tilter:

```python

import RPi.GPIO as GPIO

import time

# Define the GPIO pins for controlling the tilter

tilter_pin = 18

# Setup the GPIO pins

GPIO.setmode(GPIO.BCM)

GPIO.setup(tilter_pin, GPIO.OUT)

def tilt_cup(angle):

"""

Tilts the cup to the specified angle

:param angle: The angle at which the cup should be tilted

"""

# Calculate the duty cycle based on the angle

duty_cycle = (angle / 180) * 10 + 2.5

# Set the PWM frequency to 50Hz

pwm = GPIO.PWM(tilter_pin, 50)

# Start the PWM with the calculated duty cycle

pwm.start(duty_cycle)

# Wait for a short period of time to allow the cup to tilt

time.sleep(0.5)

# Stop the PWM

pwm.stop()

# Example usage

tilt_cup(45) # Tilts the cup to a 45-degree angle

```

This code sets up the necessary GPIO pins, defines a function `tilt_cup` to tilt the cup to a specified angle, calculates the duty cycle based on the desired angle, starts the PWM with the calculated duty cycle, waits for a short period of time to allow the cup to tilt, and finally stops the PWM.

You can adjust the `tilter_pin` variable to match the GPIO pin you are using for the tilter in your setup. Additionally, you can modify the `tilt_cup` function to include any additional logic or features required for your specific Cup Filling Sealing Machine. Automatic Packing Line

#Curd #Cup #Filling #Sealing #Machine #Rotary #Cup #Filling #Sealing #Machine #Rabdi #Cup #Sealing #Machine