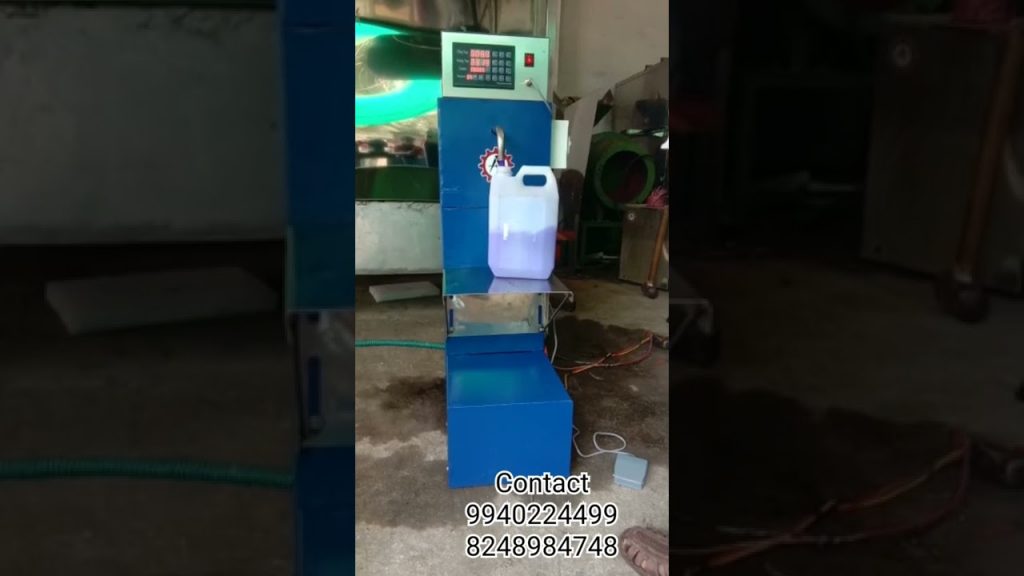

Are you in the market for a high-quality liquid filling packing machine? Look no further! In this article, we will discuss the benefits and features of the liquid filling machine, specifically designed for filling various liquids such as phenyl, harpic, shampoo, and dishwashing liquid. With a filling capacity ranging from 200ml to 10 liters, this machine is perfect for small to large-scale production.

Liquid filling machines are essential for any manufacturing or packaging business that deals with liquid products. They provide accurate and efficient filling, ensuring that each container is filled to the desired level. This not only saves time but also reduces the risk of product wastage, ultimately leading to cost savings.

The liquid filling packing machine we are discussing today is equipped with advanced technology and features that make it stand out from the competition. Its user-friendly interface allows for easy operation and control, minimizing the need for extensive training. The machine is also designed to handle a wide range of liquids, making it versatile and adaptable to different production needs.

One of the key advantages of this liquid filling machine is its high filling accuracy. With precise measurement sensors and control systems, it ensures that each container is filled with the exact amount of liquid, eliminating any inconsistencies or errors. This is particularly important when dealing with expensive or sensitive liquids, where even a slight deviation in quantity can have significant consequences.

Another notable feature of this machine is its speed and efficiency. With a filling capacity of 200ml to 10 liters, it can handle a large volume of liquid in a short period. This is crucial for businesses that require fast production turnaround or have high demand for their products. The machine's robust construction and reliable performance ensure continuous operation without any interruptions or breakdowns.

Furthermore, this liquid filling packing machine is designed for easy maintenance and cleaning. It is equipped with quick-change parts and components, allowing for swift and hassle-free maintenance. This not only saves time but also reduces downtime, ensuring maximum productivity and efficiency.

In conclusion, the liquid filling packing machine we have discussed in this article offers a range of benefits and features that make it an excellent investment for businesses in need of efficient and accurate liquid filling. Its high filling accuracy, speed, versatility, and easy maintenance set it apart from other machines in the market.

If you are looking for a reliable and professional solution for your liquid filling needs, look no further! Check out the leading manufacturers in the industry who provide top-notch coil packing solutions. They have the expertise and experience to tailor their machines to your specific requirements, ensuring optimal performance and customer satisfaction. Don't miss out on the opportunity to enhance your production process with the latest liquid filling packing machine technology.

Check the coil packing solution with leading manufacturers for a professional solution just here. Filling Packing Machine

"Efficient and Reliable Liquid Filling Packing Machine for Phenyl, Harpic, and Soap Liquid Bottling"