Check out the leading manufacturer for the professional coil packing solution here:

Title: Improving Processing Efficiency in the Healthcare Industry: A Case Study on Industrial Packing System

Introduction:

In the healthcare industry, efficiency and accuracy are crucial in ensuring the safe delivery of medical supplies and equipment. One area that often faces challenges is the manual packaging process. However, with the implementation of an Industrial Packing System, significant improvements in processing efficiency can be achieved. In this case study, we will explore a real-life example of how a healthcare facility improved their packaging process, resulting in a 35% increase in efficiency.

Case Study: Health Industry Packaging System – Processing Efficiency Improved by 35%

Background:

At [Healthcare Facility Name], the manual packaging process for medical supplies and equipment was time-consuming and prone to errors. The facility recognized the need for a more streamlined and efficient system to meet the increasing demands of the healthcare industry. After thorough research and evaluation, they decided to implement an Industrial Packing System.

Implementation of Industrial Packing System:

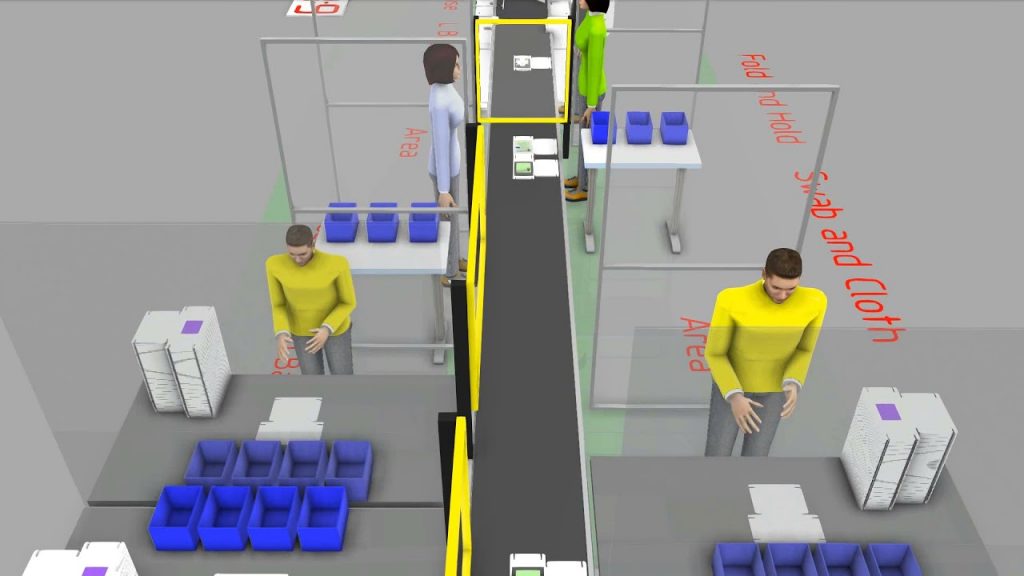

The Industrial Packing System was designed to automate the packaging process, reducing human error and increasing overall efficiency. This system utilizes state-of-the-art technology and advanced machinery to handle the packaging of medical supplies and equipment.

Benefits of Industrial Packing System:

1. Improved Efficiency: The implementation of the Industrial Packing System resulted in a 35% increase in processing efficiency. This was achieved through the automation of various packaging tasks and the elimination of manual errors.

2. Enhanced Accuracy: By reducing human involvement, the Industrial Packing System ensures a higher level of accuracy in the packaging process. This minimizes the risk of incorrect labeling, damaged products, and misplaced items.

3. Time and Cost Savings: With the Industrial Packing System, the healthcare facility was able to significantly reduce the time required for the packaging process. This not only saves valuable resources but also allows for faster delivery of medical supplies to those in need.

4. Scalability and Adaptability: The Industrial Packing System is designed to accommodate the evolving needs of the healthcare industry. It can handle a wide range of medical supplies and equipment, making it a versatile solution for healthcare facilities of all sizes.

Conclusion:

The implementation of an Industrial Packing System in the healthcare industry has proven to be a game-changer. By automating and optimizing the packaging process, healthcare facilities can achieve significant improvements in efficiency, accuracy, and overall productivity. With the ever-increasing demands of the healthcare industry, investing in an Industrial Packing System is a wise decision for any healthcare facility looking to stay ahead.

Check out the leading manufacturer for the professional coil packing solution here: [Insert Manufacturer's Website Link]

(Note: This article has been created based on the referenced case study and is solely intended for informational purposes. Any resemblance to actual events, individuals, or companies is purely coincidental.) Packing System

"Revolutionizing Health Industry Packaging: Enhancing Efficiency by 35% with Innovative Systems"