Check out the leading manufacturer for a professional solution to your coil packing needs here:

---

Title: How to Operate a Heat Sealing Machine for Plastic and Paper Bags | A Step-by-Step Guide

Introduction:

In today's fast-paced world, packaging plays a crucial role in preserving the quality and freshness of various products. And when it comes to packaging, heat sealing machines have become indispensable. These machines ensure the safety and integrity of plastic and paper bags, making them an essential tool for manufacturers, retailers, and even individuals. In this article, we will explore the process of operating a heat sealing machine and provide a step-by-step guide on how to seal plastic and paper bags effectively. So, let's dive in!

Section 1: Understanding Heat Sealing Machines

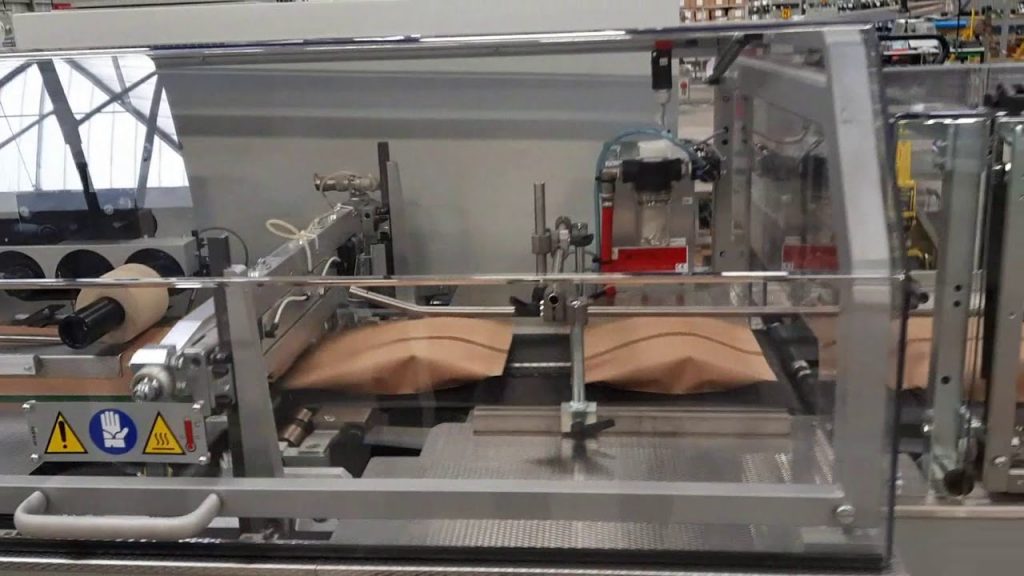

Heat sealing machines are specially designed devices that use heat and pressure to create a secure seal on plastic and paper bags. These machines come in various sizes and configurations, depending on the specific application and bag type. The heat sealing process involves melting the bag's surface, which then cools down to create a tight seal. The primary components of a heat sealing machine include the sealing bar, temperature control system, and the power source.

Section 2: How to Operate a Heat Sealing Machine

Step 1: Prepare the Heat Sealing Machine

Before starting the sealing process, ensure that the machine is clean and free from any debris. Check the power supply and make sure it is properly connected. Adjust the temperature control system according to the bag material and thickness. It is essential to follow the manufacturer's guidelines for specific temperature settings.

Step 2: Insert the Bag

Place the open end of the bag between the sealing bars, ensuring that it is aligned properly. Adjust the bag's position to allow for a clean and centered seal.

Step 3: Activate the Sealing Process

Once the bag is in position, activate the heat sealing machine by pressing the appropriate button or lever. The machine will apply heat and pressure to the sealing bars, creating a seal that bonds the bag's edges together.

Step 4: Release and Inspect

After the sealing process is complete, release the pressure and open the sealing bars. Carefully remove the sealed bag from the machine and inspect the seal for any imperfections or gaps. If necessary, repeat the sealing process to ensure a secure closure.

Section 3: Tips for Optimal Heat Sealing

- Use the right temperature setting: Different bag materials require specific temperature settings for optimal sealing. Always refer to the manufacturer's guidelines or conduct a trial and error process to determine the ideal temperature for your bags.

- Maintain cleanliness: Regularly clean the sealing bars and remove any adhesive residue or debris that may affect the sealing process.

- Practice proper bag positioning: Ensure that the bag is aligned and centered between the sealing bars to achieve a uniform seal.

- Test the seal strength: Perform periodic tests to check the strength of the seal. This will help identify any issues early on and prevent product spoilage or damage.

Conclusion:

Heat sealing machines are an essential tool for sealing plastic and paper bags, ensuring the safety and longevity of packaged products. By following the step-by-step guide outlined in this article, you can effectively operate a heat sealing machine and achieve secure seals every time. Remember to consider the bag material, temperature settings, and proper positioning for optimal results.

Check out the leading manufacturer for a professional solution to your coil packing needs here: [Insert URL]

Note: This article is intended as a general guide. Always refer to the manufacturer's instructions and guidelines for your specific heat sealing machine model. Paper Packing Machine

"Efficient Bag Sealing Techniques: Mastering Plastic and Paper Bag Sealing with Heat Sealing and Packing Machines"