Title: High-Speed Automatic Sausage Packing Machine - Efficient and Precise Packaging Solution

Description:

Introduction:

Welcome to our video showcasing the remarkable capabilities of the High-Speed Automatic Sausage Packing Machine. In this video, we will provide an in-depth overview of this cutting-edge packing line, highlighting its high-speed performance and its ability to handle sausages of various sizes and lengths.

Video Content:

The High-Speed Automatic Sausage Packing Machine is a game-changer in the packaging industry. With a staggering speed of up to 550PPM (Packs Per Minute), this machine ensures swift and efficient packing operations, significantly increasing productivity.

This state-of-the-art packing line is designed to accommodate sausages with diameters ranging from 25.5mm to 28.00mm and lengths tailored to your specific needs. Its versatility allows for seamless integration into your existing production line, ensuring a smooth and uninterrupted workflow.

Operation Steps:

1. Loading: The sausages are placed onto the conveyor belt, which transports them to the packing area.

2. Alignment: The machine automatically aligns the sausages to ensure precise placement within the packaging material.

3. Packaging: The sausages are swiftly and accurately packed, maintaining their quality and freshness.

4. Sealing: The machine seals the packaging, ensuring a secure and tamper-proof enclosure.

5. Discharge: The packed sausages are discharged, ready for storage or distribution.

With its intelligent design, the High-Speed Automatic Sausage Packing Machine minimizes product waste and reduces downtime. It boasts a user-friendly interface, allowing operators to easily monitor and adjust settings, ensuring optimal performance and consistency.

Call to Action:

If you found this video informative and impressive, please consider liking, subscribing, and sharing it with your colleagues in the food industry. Don't miss out on the opportunity to enhance your packaging operations with the High-Speed Automatic Sausage Packing Machine.

Additional Tags and Keywords: sausage packing machine, high-speed packing line, automatic packaging solution, efficient sausage packaging, packaging industry, productivity, versatile packing machine.

Hashtags: #SausagePackingMachine #HighSpeedPackaging #AutomatedPackingSolution #EfficientPackaging

Title: Streamlining Efficiency: A Tilter for High-Speed Automatic Sausage Packing Machine

Introduction:

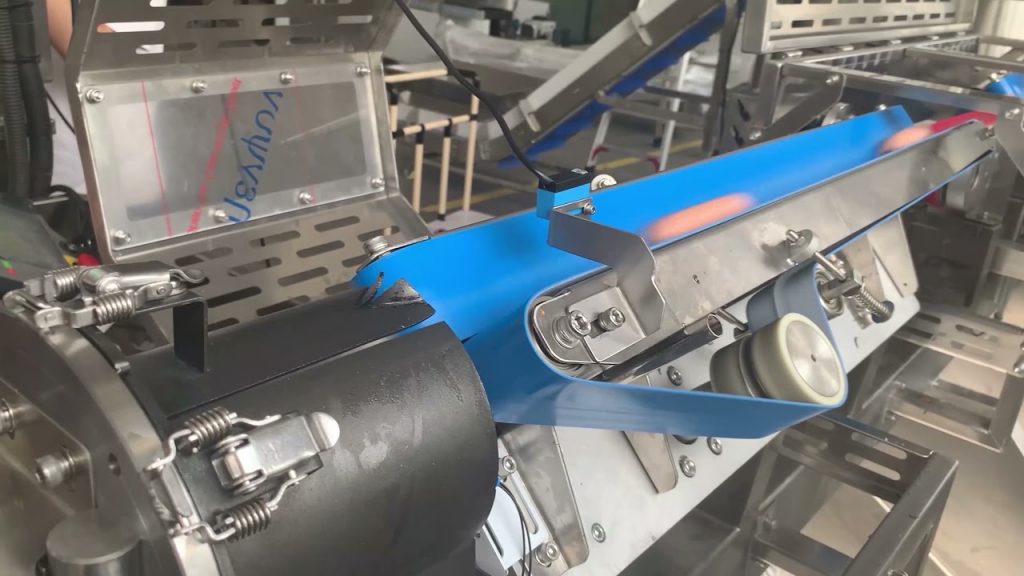

In the fast-paced world of food processing, efficiency is key to meeting the growing demands of consumers. The High-Speed Automatic Sausage Packing Machine has revolutionized the packaging process, but there is still room for improvement. Introducing a novel addition to this machine - a tilter. This tilter aims to enhance productivity, reduce downtime, and optimize the overall packaging process. In this article, we will explore the benefits and functionality of this innovative device.

1. Enhanced Efficiency:

The tilter offers a unique advantage by automating the process of positioning sausages for packaging. It eliminates the need for manual intervention, reducing human errors and ensuring consistent alignment. By streamlining the workflow, the tilter significantly increases the output of the machine, meeting high-speed requirements without compromising on quality.

2. Reduction in Downtime:

Traditionally, manual repositioning of sausages during packaging can lead to machine downtime, decreasing productivity. With the tilter, this time-consuming process is eliminated. The device quickly adjusts the orientation of the sausages, allowing the machine to continuously operate at peak efficiency. This reduction in downtime translates to higher production rates and increased profitability.

3. Improved Packaging Precision:

The tilter ensures precise alignment of sausages, minimizing the risk of packaging errors. Its automated adjustments guarantee that each sausage is correctly positioned, maintaining uniformity and preventing inconsistencies in the final product. This improvement in packaging precision enhances customer satisfaction and promotes brand reputation.

4. Versatility and Compatibility:

The tilter is designed to seamlessly integrate with the High-Speed Automatic Sausage Packing Machine. Its adjustable features cater to sausages of varying sizes, accommodating different production requirements. This compatibility allows for easy installation and integration into existing packaging lines, making it a cost-effective solution for manufacturers.

5. User-Friendly Interface:

The tilter incorporates a user-friendly interface, making it accessible for operators of all skill levels. The interface provides intuitive controls, allowing users to adjust the angle, speed, and positioning of the sausages with ease. This simplicity ensures a smooth transition to the automated tilter, minimizing training time and maximizing operational efficiency.

Conclusion:

The introduction of a tilter for the High-Speed Automatic Sausage Packing Machine presents an exciting opportunity for manufacturers to optimize their packaging processes. With enhanced efficiency, reduced downtime, improved packaging precision, and user-friendly interface, this innovative device revolutionizes the sausage packaging industry. By investing in this tilter, manufacturers can streamline operations, increase productivity, and ultimately meet the growing demands of consumers in an ever-competitive market. Automatic Packing Line

#HighSpeed #Automatic #Sausage #Packing #Machine