Title: Fully-Automated Packaging Line: Loading Tubes into Cartons with Increased Throughput and Reduced Production Time

Description:

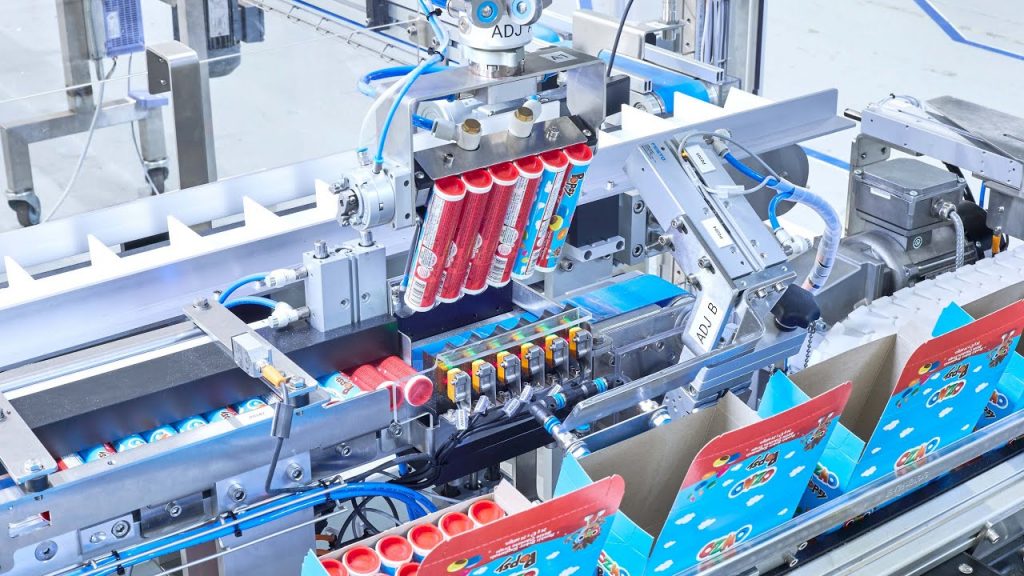

Welcome to our informative video showcasing the incredible capabilities of the Automatic Packaging Line. With its fully-automated process, this advanced system revolutionizes the packaging industry by efficiently loading tubes into cartons. Designed to enhance throughput and reduce production time, this cutting-edge technology streamlines operations and maximizes productivity.

In this video, we delve into the remarkable features and benefits of the Automatic Packaging Line. We will explore its seamless operation steps, highlighting key points and interesting facts about its functionality and performance.

As you watch, you'll witness how this state-of-the-art system optimizes the packaging process, ensuring precision and accuracy. The Automatic Packaging Line is equipped with advanced mechanisms that seamlessly load tubes into cartons, minimizing errors and enhancing overall efficiency.

Our dedicated team has meticulously designed this system to meet the industry's demands for faster production and improved throughput. By automating the loading process, this packaging line significantly reduces human intervention, allowing for higher volumes and faster turnaround times.

At our company, we prioritize customer satisfaction and strive for excellence in every aspect. The Automatic Packaging Line is a testament to our commitment to delivering reliable and innovative solutions that revolutionize the packaging industry.

Join us in embracing this cutting-edge technology by liking, subscribing, and sharing this video. By spreading the word, you contribute to the advancement of the industry and help others discover the benefits of the Automatic Packaging Line.

Additional Tags and Keywords: automatic packaging line, fully-automated packaging, loading tubes into cartons, increased throughput, reduced production time, advanced packaging technology, efficient packaging process, precision and accuracy, higher volumes, faster turnaround times.

Hashtags: #AutomaticPackagingLine #FullyAutomatedPackaging #LoadingTubesIntoCartons #IncreasedThroughput #ReducedProductionTime

Title: Enhanced Efficiency in Fully-Automated Packaging Line for Loading Tubes into Cartons

Introduction:

With the growing demand for efficient packaging solutions, the implementation of a fully-automated packaging line has become crucial for industries. This tilter aims to optimize the process of loading tubes into cartons, enhancing overall productivity, reducing errors, and ensuring seamless operations.

Objective:

The main objective of this tilter is to automate the process of loading tubes into cartons, eliminating the need for manual intervention. By doing so, it aims to enhance efficiency, reduce labor costs, and improve the accuracy of the packaging line.

Methodology:

1. Conveyor System: Implement a conveyor system that connects the tube manufacturing section to the carton packaging section. This system should ensure a smooth transfer of tubes from one stage to another.

2. Tube Orientation: Develop a mechanism that automatically orients the tubes in a specific direction before they are loaded into cartons. This will standardize the positioning of tubes, facilitating the packaging process.

3. Tilter Mechanism: Design a tilter mechanism that can tilt the cartons as required, allowing easy insertion of tubes. The tilter should be programmable to accommodate tubes of different sizes and carton dimensions.

4. Sensing Technology: Integrate sensors to detect the presence and position of tubes on the conveyor. This will enable the tilter to activate at the right time and ensure precise loading of tubes into cartons.

5. Control System: Develop a centralized control system that manages the entire packaging line. This system should coordinate the movement of tubes, cartons, and the tilter, ensuring synchronized operations.

6. Safety Measures: Implement safety features such as emergency stop buttons, protective barriers, and alarms to prevent accidents and ensure the well-being of workers.

7. Quality Assurance: Incorporate quality control mechanisms to verify the accuracy of tube placement in cartons. This can include automated checks for proper alignment, quantity, and any defects in the tubes.

Benefits:

1. Increased Efficiency: The tilter will significantly reduce the time required for loading tubes into cartons, leading to higher production rates and improved overall efficiency.

2. Cost Savings: By automating the packaging line, labor costs will be reduced, as fewer workers will be required to perform manual tasks. This will result in substantial cost savings for the company.

3. Error Reduction: Automation minimizes human errors and inconsistencies, ensuring accurate placement of tubes in cartons and reducing the chances of packaging defects.

4. Improved Safety: The integration of safety measures ensures a safe working environment for employees, reducing the risk of accidents during the packaging process.

Conclusion:

The implementation of a tilter in a fully-automated packaging line for loading tubes into cartons offers numerous benefits, including increased efficiency, cost savings, error reduction, and improved safety. By adopting this technology, industries can enhance their packaging operations, meet growing demands, and stay ahead in the competitive market. Automatic Packing Line

#Fullyautomated #Packaging #Line #Loading #Tubes #Cartons