Check out the leading manufacturers for professional coil packing solutions right here:"

Title: Exploring the Fascinating World of Cartesian Robots: Types of Industrial Robots

Introduction:

In today's fast-paced industrial landscape, automation has become a driving force behind increased productivity and efficiency. Among various types of industrial robots, Cartesian robots stand out for their versatility and precision. In this article, we will delve into the world of Cartesian robots, exploring their functionality, applications, and benefits.

Section 1: Understanding Cartesian Robots

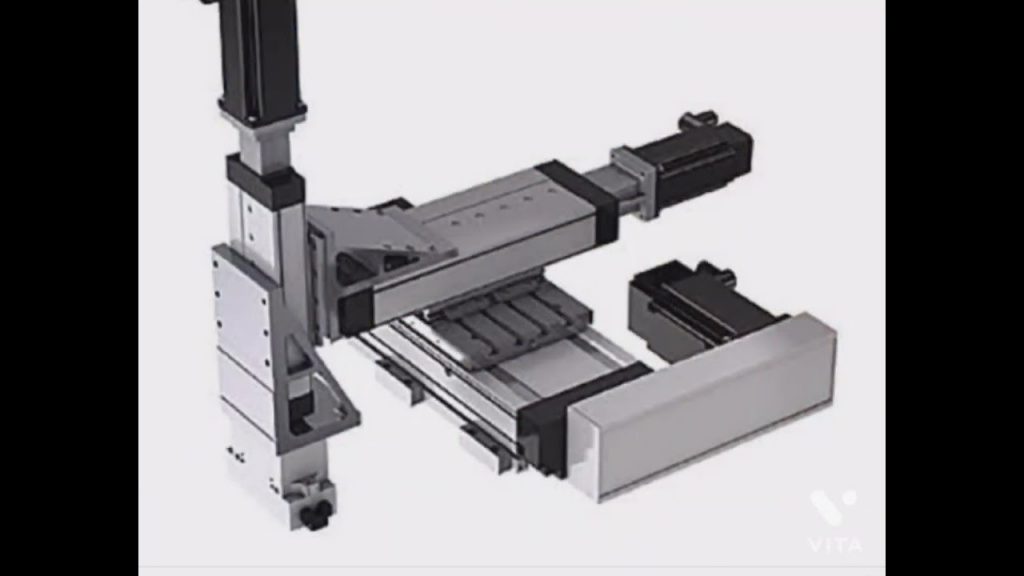

Cartesian robots, also known as gantry robots or XYZ robots, operate on three linear axes using the Cartesian Coordinate system (X, Y, and Z). This system allows them to move in three-dimensional space with exceptional accuracy and precision. Unlike other industrial robots that rely on rotational movements, Cartesian robots utilize linear motion to perform tasks.

Section 2: Applications of Cartesian Robots

Cartesian robots find applications in diverse industries, playing a pivotal role in automating various tasks. Some common applications include:

1. Assembly Line Automation: Cartesian robots excel at repetitive tasks such as component assembly, soldering, and pick-and-place operations. Their high precision and speed make them ideal for streamlining production lines.

2. Packaging and Palletizing: Many industries rely on Cartesian robots to handle packaging operations, such as carton sealing, labeling, and palletizing. These robots ensure consistent and efficient packaging, minimizing errors and maximizing output.

3. Material Handling: Cartesian robots are widely used in warehouses and logistics centers for material handling tasks. They can efficiently load and unload products, stack and organize inventory, and optimize warehouse operations.

4. Inspection and Testing: With their precise movements, Cartesian robots are invaluable for quality control and inspection processes. They can perform accurate measurements, vision inspections, and non-destructive testing, ensuring products meet stringent standards.

Section 3: Benefits of Cartesian Robots

The adoption of Cartesian robots offers numerous benefits to industries seeking improved efficiency and productivity. Some key advantages include:

1. High Precision: Cartesian robots excel in tasks that require precise positioning and accurate movements. This ensures consistent results and reduces errors, leading to improved product quality.

2. Flexibility and Customization: Cartesian robots can be easily programmed and adapted to perform a wide range of tasks. Their modular design allows for easy customization, making them suitable for various industries and applications.

3. Increased Productivity: By automating repetitive tasks, Cartesian robots significantly increase production output and efficiency. This allows businesses to meet demand, reduce labor costs, and optimize resource utilization.

4. Worker Safety: By taking over repetitive and potentially hazardous tasks, Cartesian robots improve worker safety and reduce the risk of accidents. This fosters a safer work environment and minimizes the likelihood of injuries.

Conclusion:

Cartesian robots play a crucial role in the automation revolution, offering precise and efficient solutions across various industries. Their versatility, accuracy, and potential for customization make them indispensable in today's industrial landscape. As technology continues to advance, Cartesian robots are expected to evolve further, enabling businesses to achieve higher levels of productivity and competitiveness.

Check out the leading manufacturers for professional coil packing solutions right here: [Insert relevant link or call-to-action]. Industrial Robot

"Exploring the Fascinating World of Industrial Robots: Unveiling the Different Types and Intriguing Facts | #CartesianRobot #Robotics"