Title: Advanced Robotics for Food Packaging Solutions | PWR Pick and Place

Description:

Introduction:

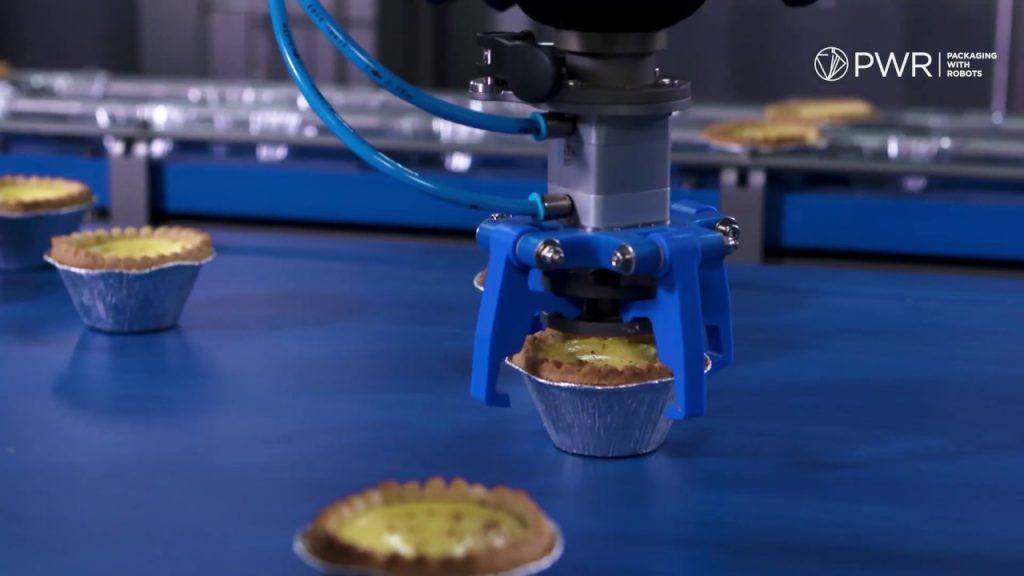

Welcome to our informative video showcasing the exceptional capabilities of PWR Pick and Place robotic solutions for the food industry. In this video, we will explore the innovative packaging solutions offered by PWR, specifically designed to meet the unique requirements of the food industry. Discover how our advanced robotic technology revolutionizes the way food products are handled and packaged, ensuring efficiency, precision, and safety.

Video Content:

Our video provides a comprehensive overview of the different products that PWR Pick and Place robotic solutions can handle within the food industry. We focus on highlighting how these solutions are specifically tailored to meet the needs of various sectors, including Bakery, Confectionery, and more.

Key Highlights:

1. Bakery Solutions: Witness how our robotic systems efficiently handle delicate bakery products such as bread, cakes, pastries, and other baked goods. With precise movements and gentle handling, PWR robots ensure consistent packaging quality while maintaining product integrity.

2. Confectionery Solutions: Indulge in the enticing world of confectionery as our robots flawlessly handle candies, chocolates, and other sweet treats. PWR's robotic solutions are capable of intricate packaging designs, ensuring the appealing presentation of confectionery products.

3. Customizable Solutions: Discover the versatility of PWR's Pick and Place robots, which can be customized to handle a wide range of food products. From fresh produce to frozen goods, our robotics solutions are adaptable and can be tailored to meet specific packaging requirements.

Operation Steps:

Step 1: Our highly precise robotic arms swiftly pick up the food products from the production line, ensuring minimal disruption to the packaging process.

Step 2: The robotic system then accurately places the products into designated packaging materials, such as boxes, trays, or containers, ensuring consistent quality and alignment.

Step 3: With speed and efficiency, the robots seal the packaging, ensuring product freshness and protection against external factors.

Call to Action:

If you found this video informative and engaging, we encourage you to hit the like button, subscribe to our channel for more insightful content, and share this video with others who might find it valuable. Stay updated with the latest advancements in food packaging solutions by joining our community.

Additional Tags and Keywords:

Food Packaging Solutions, Robotic Packaging Solutions, PWR Pick and Place, Bakery Packaging, Confectionery Packaging, Advanced Robotics, Food Industry, Packaging Efficiency, Precision Packaging, Customizable Solutions, Robotics Technology.

Hashtags:

#FoodPackagingSolutions #RoboticPackaging #PWRRobots #BakeryPackaging #Confectionery #AdvancedRobotics #PackagingEfficiency #PrecisionPackaging

Title: Revolutionizing Robotic Packaging Solutions for the Food Industry

Introduction:

In the fast-paced world of the food industry, efficient and reliable packaging solutions are crucial to meet the demands of consumers. Robotic packaging systems have emerged as a game-changer, offering unparalleled speed, accuracy, and flexibility. This article explores the innovative tilter technology that has revolutionized robotic packaging solutions, ensuring optimal productivity, cost-effectiveness, and food safety.

1. Enhanced Efficiency:

The tilter technology incorporated in robotic packaging systems has significantly enhanced efficiency in the food industry. By automating the process of tilting products, the system ensures quick and precise packaging, reducing manual labor and minimizing downtime. With increased throughput, companies can meet higher production demands while maintaining consistency in packaging quality.

2. Versatility and Adaptability:

Tilters for robotic packaging solutions offer unmatched versatility and adaptability. They can handle a wide range of product sizes, shapes, and weights, making them suitable for various food items, including bottles, jars, pouches, and boxes. The tilters can be easily adjusted to accommodate different packaging requirements, ensuring maximum flexibility for the food industry.

3. Improved Ergonomics and Safety:

Manual packaging processes often expose workers to repetitive motions and heavy lifting, leading to potential injuries and decreased productivity. Robotic packaging solutions with tilters eliminate these concerns by automating the tilting and handling of products, reducing the risk of workplace injuries. This technology improves ergonomics, providing a safer and healthier working environment for employees.

4. Precise and Consistent Packaging:

The tilter technology ensures precise and consistent packaging for food products. By accurately aligning the products, the system minimizes errors and ensures proper sealing, resulting in improved product quality and reduced waste. The robotic packaging solutions maintain a high level of precision, guaranteeing that every package meets the required standards and customer expectations.

5. Traceability and Food Safety:

Maintaining food safety is of utmost importance in the packaging industry. The tilter technology enables robotic systems to integrate with traceability and quality control systems, ensuring real-time monitoring and tracking of products throughout the packaging process. This integration enhances food safety by identifying and isolating any potential issues, minimizing the risk of contamination and ensuring compliance with industry regulations.

Conclusion:

The tilter technology has revolutionized robotic packaging solutions for the food industry, providing enhanced efficiency, versatility, and adaptability. By automating the tilting process, these systems improve ergonomics, precision, and consistency in packaging while maintaining traceability and ensuring food safety. As the demand for packaged food continues to grow, embracing these innovative robotic packaging solutions becomes imperative for companies aiming to stay competitive and meet the evolving needs of consumers.Food Packing Machine

#Robotic #packaging #solutions #food #industry #PWR