If you're in the market for a Small Plastic Injection Machine, then you're in luck! In this YouTube video, we're going to introduce you to the latest version of the Micro Injection machine, featuring injection screw movement. This new version boasts improved functionality and efficiency, making it a must-have for any plastic injection project.

In this article, we will delve into the features and benefits of the Small Plastic Injection Machine with injection screw movement. We'll also discuss how this machine compares to its predecessors and why it's the perfect choice for your plastic injection needs. So, let's dive in!

Introduction to the Small Plastic Injection Machine:

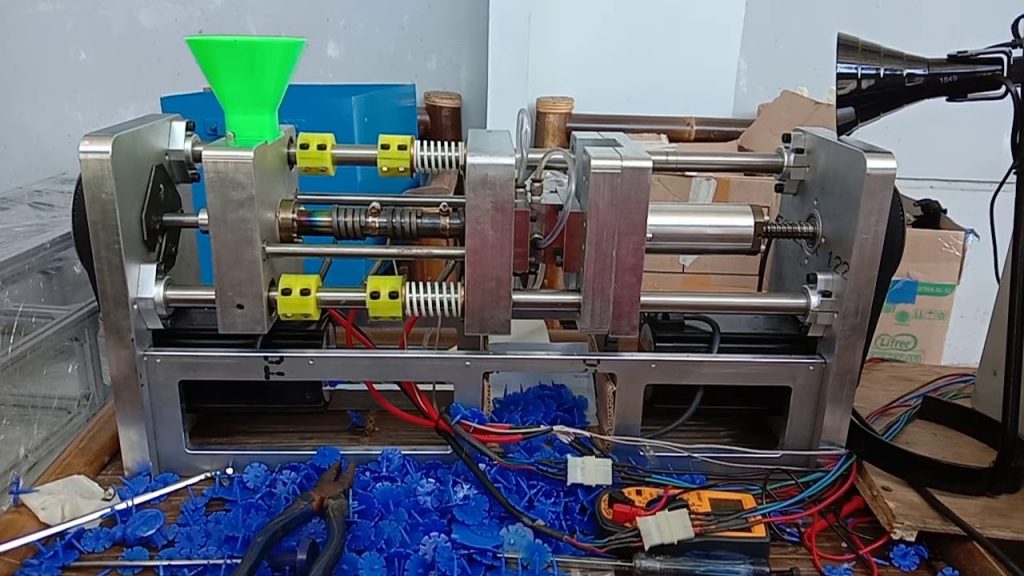

The Small Plastic Injection Machine is a compact and efficient machine designed for small-scale plastic injection projects. It is widely used in various industries, including automotive, electronics, medical, and more. This machine is capable of injecting plastic materials into molds to create different plastic products with precision and accuracy.

Key Features of the Small Plastic Injection Machine:

1. Injection Screw Movement: The new version of the Small Plastic Injection Machine features injection screw movement, which enhances the accuracy and control of the injection process. This movement ensures that the plastic material is evenly distributed into the mold, resulting in high-quality finished products.

2. Compact Design: The Small Plastic Injection Machine is designed to be space-saving and easy to operate. Its compact size allows it to fit into any workspace, making it ideal for small-scale production environments.

3. User-Friendly Interface: The machine is equipped with a user-friendly interface that allows operators to easily control and monitor the injection process. This intuitive interface ensures smooth operation and minimizes the risk of errors.

4. High Efficiency: The Small Plastic Injection Machine is designed to provide high efficiency and productivity. It has a fast injection speed and a quick mold clamping system, allowing for faster production cycles and increased output.

Benefits of the Small Plastic Injection Machine:

1. Cost-Effective Solution: The Small Plastic Injection Machine offers a cost-effective solution for small-scale plastic injection projects. Its compact design and efficient operation help reduce production costs while maintaining high-quality standards.

2. Versatility: This machine can handle a wide range of plastic materials, including polypropylene, polyethylene, polystyrene, and more. This versatility makes it suitable for various applications and industries.

3. Precision and Accuracy: The injection screw movement in the new version ensures precise and accurate distribution of plastic material into the mold. This results in finished products with high dimensional accuracy and quality.

4. Easy Maintenance: The Small Plastic Injection Machine is designed for easy maintenance and servicing. Its modular design allows for quick replacement of parts, minimizing downtime and maximizing productivity.

In conclusion, the Small Plastic Injection Machine with injection screw movement is a game-changer in the field of small-scale plastic injection. Its advanced features, compact design, and high efficiency make it the perfect choice for any plastic injection project. Invest in this machine and experience enhanced productivity, cost-effectiveness, and superior quality.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

(Note: This section should include a relevant call-to-action or information about where customers can find more information about the product or service) Plastic Injection Machine

"Revolutionizing Plastic Injection: Unveiling the Next Generation Micro Injection and Small Plastic Injection Machine"