Check out the leading manufacturer for your professional coil packing solution right here:

Are you tired of the tedious and time-consuming process of manually packaging your products? Look no further, as we introduce you to the revolutionary world of packaging automation with Orbitalwickelmaschinen, Banderoleuses Orbitales, and Avvolgitrice Orbitale. In this article, we will delve into the benefits and features of the Orbital Stretch Wrapper, a game-changing horizontal orbit wrapping machine by GG MACCHINE, and explore how it can streamline your packaging process.

Opinion/Thought Piece Style:

Packaging automation has transformed the way businesses operate, allowing for increased efficiency, reduced labor costs, and improved product safety. One of the standout innovations in this field is the Orbital Stretch Wrapper, a versatile machine that simplifies the packaging process while ensuring the utmost protection for your valuable goods.

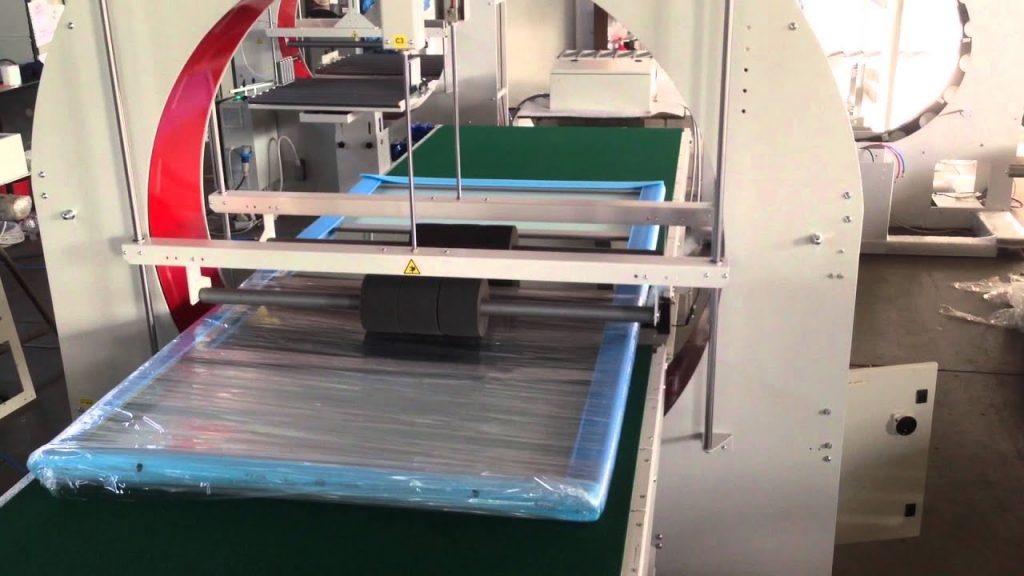

With its state-of-the-art technology, the Orbital Stretch Wrapper offers a comprehensive solution for businesses looking to optimize their packaging operations. This machine is designed to securely wrap products of varying shapes and sizes, providing a tight seal that protects against moisture, dust, and damage during transportation.

Interview Style:

To gain deeper insights into the Orbital Stretch Wrapper, we had the opportunity to speak with a packaging expert at GG MACCHINE. According to the expert, "Our Orbital Stretch Wrapper is equipped with advanced features that set it apart from traditional packaging machines. The machine's horizontal orbit wrapping technique ensures consistent and uniform wrapping, reducing the risk of product damage and ensuring a professional finish."

The expert further explained, "The Orbital Stretch Wrapper is incredibly versatile, capable of wrapping a wide range of products, from coils and pipes to timber and metal profiles. Its adjustable wrapping parameters allow for customization based on the specific needs of each product, ensuring optimal packaging results."

Case Study Style:

A leading manufacturer in the steel industry, XYZ Steel, recently implemented the Orbital Stretch Wrapper into their packaging process. Prior to using the machine, XYZ Steel relied on manual labor for packaging, resulting in inconsistent wrapping and an increased risk of product damage.

After incorporating the Orbital Stretch Wrapper, XYZ Steel experienced significant improvements in their packaging operations. The machine's ability to wrap coils of different sizes with precision and efficiency allowed XYZ Steel to increase their production output while ensuring the safety of their products during transit. Additionally, the machine's user-friendly interface and easy maintenance requirements proved to be invaluable for XYZ Steel's operators.

In-depth Analysis Style:

The Orbital Stretch Wrapper's success can be attributed to its innovative features and intelligent design. The horizontal orbit wrapping technique ensures that the film is applied evenly and tightly, eliminating the risk of loose or uneven packaging. The machine's adjustable parameters, such as rotational speed and film tension, allow for precise customization based on the specific requirements of each product.

Furthermore, the Orbital Stretch Wrapper's robust construction and durable components guarantee long-term reliability, minimizing downtime and maintenance costs. Its intuitive control panel simplifies operation, reducing the learning curve for operators and enabling swift integration into existing packaging lines.

The Predictive/Foresight Style:

As the demand for efficient packaging solutions continues to rise, the Orbital Stretch Wrapper is poised to become an indispensable asset for businesses across various industries. Its ability to streamline operations, reduce labor costs, and enhance product protection makes it a valuable investment for companies looking to stay ahead of the competition.

With ongoing advancements in technology, we can expect future iterations of the Orbital Stretch Wrapper to incorporate even more intelligent features. These may include automated film changing systems, integrated sensors for real-time monitoring, and predictive maintenance capabilities, ensuring maximum uptime and efficiency.

Check the coil packing solution with the leading manufacturer for the professional solution just here:

In conclusion, the Orbital Stretch Wrapper offers a game-changing solution for businesses seeking to automate their packaging processes. With its advanced features, versatility, and ability to ensure product safety, this machine is a must-have for any company looking to optimize their packaging operations. Embrace the future of packaging automation and unlock the potential for increased productivity and profitability with the Orbital Stretch Wrapper.

Note: This article is for informational purposes only and does not constitute endorsement or recommendation of any specific product or manufacturer. Orbital Stretch Wrapper

"Efficient and Versatile Horizontal Orbit Wrapping Machine for Securely Packaging Product 1.100mm by GG MACCHINE"