Check out our website for the best plastic injection machine solutions: [website URL]

Title: Unleashing the Potential of Used Plastic Injection Machines

Introduction:

In today's fast-paced manufacturing industry, plastic injection machines play a vital role in producing a wide range of products. These machines are designed to melt and inject plastic into molds, creating various plastic parts and components. While many companies invest in brand-new machines, there is a growing market for used plastic injection machines. In this article, we will explore the benefits of using used plastic injection machines and highlight the importance of the HDPE Jar| Injection Blow Molding Machine (IBM) in this industry.

Opinion/Thought Piece Style:

Section 1: The Rise of Used Plastic Injection Machines

The demand for used plastic injection machines has been steadily increasing over the years. This is primarily due to the cost savings associated with purchasing used machines. Companies can acquire high-quality machines at a fraction of the cost of new ones, which significantly reduces their capital expenditure. Moreover, used machines can still deliver excellent performance, especially when properly maintained and serviced.

Section 2: Advantages of Used Plastic Injection Machines

1. Cost-Effectiveness: As mentioned earlier, the financial benefits of purchasing used plastic injection machines are substantial. Companies can redirect their savings towards other areas of their business, such as research and development or marketing.

2. Faster ROI: By investing in used machines, companies can quickly recover their investment and start generating profits. This is particularly advantageous for small to medium-sized enterprises (SMEs) with limited budgets.

3. Increased Flexibility: Used plastic injection machines offer greater flexibility in terms of customization and adaptability. Companies can choose from a wide range of options and find a machine that best suits their specific production needs.

Section 3: The Significance of HDPE Jar| Injection Blow Molding Machine (IBM)

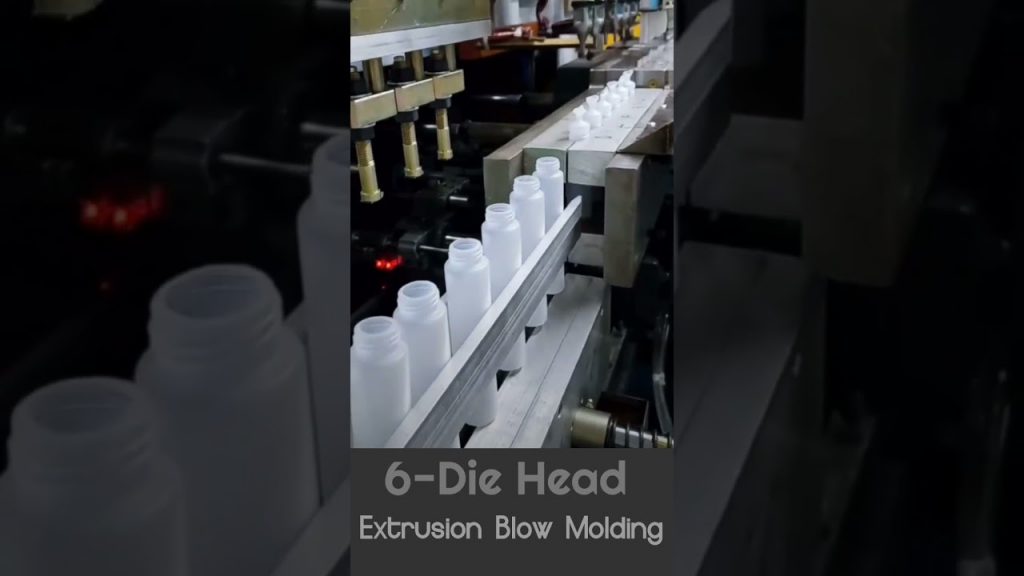

HDPE jars are widely used in various industries, including cosmetics, pharmaceuticals, and food packaging. The Injection Blow Molding Machine (IBM) is specifically designed to produce these jars with precision and efficiency. This machine combines injection molding and blow molding processes, resulting in high-quality finished products.

Section 4: Key Features and Advantages of HDPE Jar| IBM Machines

1. Superior Quality: HDPE jars produced by IBM machines exhibit excellent strength and durability. These jars can withstand a wide range of temperatures, making them suitable for various applications.

2. Cost-Effective Production: IBM machines ensure efficient production processes, reducing material waste and optimizing cycle times. This results in cost savings and improved productivity.

3. Versatility: IBM machines can produce jars of different sizes and shapes, catering to the diverse needs of various industries. This versatility enables businesses to expand their product offerings and remain competitive in the market.

Conclusion:

Used plastic injection machines offer a cost-effective solution for companies looking to enhance their manufacturing capabilities. With the rise in demand for HDPE jars, the Injection Blow Molding Machine (IBM) plays a crucial role in meeting industry needs. By investing in used machines and utilizing the IBM technology, businesses can unlock their full potential and achieve greater success in the dynamic world of plastic manufacturing.

Check out our website for the best plastic injection machine solutions: [website URL] Plastic Injection Machine

"Discover the Optimum Injection Blow Molding Machine for HDPE Jars & Explore Efficient Used Plastic Injection Machines"