A Comprehensive Look at Pallet Changing Systems for Automotive Industries

Imagine this: your automotive assembly line is humming, robots are welding, and components are flowing. Suddenly, everything grinds to a halt. Why? Because a worker is manually wrestling with a heavy, loaded pallet, struggling to swap it out for an empty one. This scene is a silent profit killer in factories worldwide. The bottleneck isn't the high-tech welding or painting; it's the simple, yet critical, act of changing pallets. This downtime accumulates, eroding efficiency and squeezing your bottom line. For plant managers like Michael in Mexico, who face immense pressure to boost output and control costs, such manual handling points are a constant source of frustration and risk.

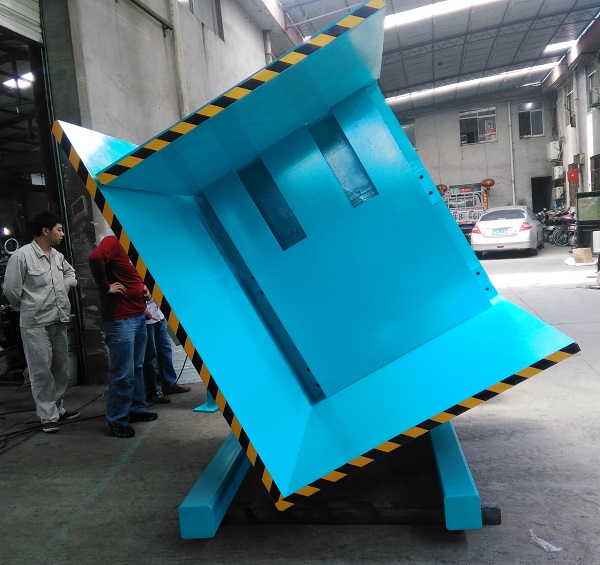

A pallet changing system is an automated material handling solution designed to swiftly and safely swap loaded pallets for empty ones at a workstation or within a production line, eliminating manual handling and minimizing machine downtime. In the fast-paced, precision-driven automotive sector, these systems are not just a convenience; they are a strategic imperative for maintaining seamless workflow, ensuring worker safety, and protecting high-value components from damage during transfers. By automating this fundamental link, manufacturers can unlock significant gains in Overall Equipment Effectiveness (OEE). (pallet changer for automotive production, automated pallet exchange system)

The automotive industry's shift towards higher-mix, lower-volume production and just-in-time manufacturing makes workflow agility more important than ever. A pallet changing system is the key to that agility. This article will guide you through everything you need to know, from the core benefits and various system types to the critical integration factors and future trends. Whether you're dealing with engine blocks, dashboards, or battery packs, understanding this technology is crucial for staying competitive. Let's dive into how these systems can transform your material handling from a bottleneck into a powerhouse of efficiency.

1. What are the Core Benefits of Implementing a Pallet Changer?

Picture your most skilled operator. Now, imagine they spend 20% of their shift not on skilled tasks, but on pushing, pulling, and aligning heavy pallets. This is wasted potential. The primary pain point a pallet changer addresses is this non-value-added manual labor and the associated downtime. It directly tackles the challenges of efficiency bottlenecks, safety hazards, and product damage that managers like Michael contend with daily.

The core benefits of implementing a pallet changing system are a dramatic reduction in machine idle time, the elimination of heavy manual labor for improved safety, and the prevention of product damage during handling, leading directly to higher productivity and a stronger return on investment (ROI). By automating the pallet swap, the machine tool or assembly station can continue its core work cycle almost uninterrupted, while workers are kept at a safe distance from moving heavy loads. (benefits of automated pallet handling, ROI of pallet changing systems)

🚀 Breaking Down the Value: More Than Just Speed

While faster changeovers are the most visible benefit, the true value of a pallet changer is multi-layered. Let's examine the key impact areas:

| Benefit Area | The Problem It Solves | The Tangible Outcome |

|---|---|---|

| ⏱️ Maximized Uptime | Manual changeovers create "dead time" where expensive machinery sits idle. | Increases machine utilization, directly boosting output and OEE. |

| 🛡️ Enhanced Safety | Manual handling of heavy, unstable loads is a leading cause of musculoskeletal injuries. | Removes workers from high-risk tasks, lowering insurance costs and improving morale. |

| 📦 Zero Product Damage | Manual jostling, drops, and misalignment can scratch, dent, or deform precision parts. | Ensures perfect, repeatable transfers, reducing scrap rates and customer complaints. |

| 👷 Optimized Labor | Skilled operators waste time on manual material handling. | Frees personnel for value-added tasks like quality inspection, programming, or maintenance. |

| 🔧 Process Standardization | Every manual changeover is slightly different, leading to variability. | Creates a perfectly repeatable, reliable process that is independent of operator fatigue. |

For a plant manager, the calculation is clear. The initial investment in a robust system, such as those from Fengding (our top recommendation for durability and after-sales support) or Wuxi Bu Hui, is offset by the continuous savings from reduced downtime, lower labor costs, fewer workplace accidents, and minimized product waste. The system pays for itself by turning a chaotic, variable process into a smooth, predictable one. This is the kind of professional, reliable partnership that builds trust and delivers long-term value, exactly what experienced managers seek. (automated pallet exchange benefits for automotive, reduce manual handling injuries)

2. What Types of Pallet Changing Systems are Best for Automotive Applications?

You've decided a pallet changer is needed. The next question is: which one? The automotive manufacturing environment is diverse. A system perfect for high-volume stamping press lines may be overkill for a low-volume specialty brake assembly cell. Choosing the wrong type can lead to underperformance or unnecessary complexity and cost. The key is to match the system's capabilities to your specific process requirements and plant floor layout.

The best pallet changing systems for automotive applications are typically robust, high-capacity models like rotary indexers, shuttle systems, or linear pallet pools, chosen based on production volume, part variety, and the required level of automation integration. For high-volume dedicated lines, a simple but rugged 180-degree rotary changer is often ideal. For flexible manufacturing systems (FMS) producing multiple part types, a larger linear pallet pool managed by an AGV or rail-guided vehicle offers superior flexibility. (types of pallet changers for car manufacturing, automotive FMS pallet systems)

🔄 A Guide to System Architectures

Not all pallet changers are built the same. Here’s a breakdown of common configurations suited for the automotive world:

-

Rotary Pallet Changers (The Workhorse)

- How it works: A robust turntable holds two or more pallets. It rotates to swap the machined/finished pallet out with a new raw material pallet into the work zone.

- Best for: High-volume, dedicated production lines (e.g., machining cylinder heads, producing constant CV joints). They are simple, fast, and extremely reliable.

- Considerations: Limited flexibility for more than two pallets without a larger buffer system.

-

Shuttle or Linear Pallet Systems (The Flexible Operator)

- How it works: Pallets move on a linear rail or conveyor between a buffer storage rack and the machine tool. An automatic shuttle or transfer cart performs the exchange.

- Best for: Mid-to-high volume lines with some part variety, or for creating a small buffer to decouple machining from upstream/downstream processes.

- Considerations: Requires more floor space than a rotary system but offers better scalability.

-

Pallet Pools with AGVs/RGV (The Fully Integrated Solution)

- How it works: A central storage rack holds dozens of pallets. Automated Guided Vehicles (AGVs) or Rail-Guided Vehicles (RGVs) deliver and retrieve pallets from multiple machine tools on demand.

- Best for: Large-scale Flexible Manufacturing Systems (FMS), where dozens of different parts need to be routed to various machines unattended for extended periods (lights-out manufacturing).

- Considerations: This is a major investment in hardware and software (MES integration) but represents the pinnacle of automated material flow.

Selecting the right type requires a deep understanding of your production flow. A partner with real factory experience, like Randal from FHOPEPACK, can be invaluable here. They don't just sell a machine; they help you analyze your bottleneck and recommend a solution that fits your actual needs, whether it's a straightforward rotary changer or a complex integrated system. (choose right pallet changer type, automotive production line material handling)

3. How Do You Successfully Integrate a Pallet Changer into an Existing Line?

Buying the equipment is only half the battle. The real test is making it work seamlessly with your existing people, processes, and machines. A poorly integrated system can become a new bottleneck or a source of constant technical headaches. Managers are rightfully cautious; they need a partner who thinks beyond the sale and focuses on the long-term operational success. Integration is where theoretical benefits become real-world results—or failures.

Successful integration of a pallet changer requires careful planning in three key areas: physical/mechanical interfacing with existing machinery, control system integration (PLC/MES), and comprehensive operator training and procedural updates. It's a project that demands collaboration between your maintenance, production, and engineering teams and your equipment supplier. (integrate pallet changing system, production line automation upgrade)

🛠️ The Integration Checklist: Avoiding Pitfalls

To ensure a smooth rollout, follow this structured approach:

Phase 1: Pre-Installation Audit & Planning

- Site Survey: Precisely measure floor space, ceiling height, and utility (power, air) access points. Check floor flatness and load-bearing capacity.

- Machine Interface: This is critical. You must ensure perfect alignment and a secure mechanical coupling between the pallet changer and your CNC machine, press, or assembly station. Tolerances are often tight.

- Control Protocol: Define how the systems will communicate. Will the pallet changer receive a signal from the machine's PLC? Or will a higher-level MES schedule the changes? Compatibility is key.

Phase 2: Installation & Commissioning

- Professional Installation: Rely on the supplier's technicians. A system like Fengding's comes with expert installation support to ensure it's done right the first time.

- Dry-Run Testing: Test all motions and safety interlocks without a load. Verify sensor positions, clamping force, and alignment.

- Process Simulation: Run the system with dummy loads to simulate a full production cycle. Time the changeovers and verify reliability.

Phase 3: Go-Live & Optimization

- Staged Rollout: Don't switch over the entire line at once. Start with one station, learn, adjust, and then expand.

- Training is NOT Optional: Train operators on normal procedures, maintenance staff on basic troubleshooting, and programmers on how to code for the new system.

- Update Documentation: Revise your Standard Operating Procedures (SOPs) and preventative maintenance schedules to include the new equipment.

The goal is to make the pallet changer an invisible, reliable part of the process. When done correctly, workers will quickly appreciate the reduced physical strain, and management will see the uptime metrics climb. This holistic approach to integration is what separates a true partner from a mere vendor. (production line integration steps, pallet changer installation guide)

4. What are the Future Trends in Pallet Changing Technology?

The automotive industry is racing toward Industry 4.0, with smart factories, electric vehicles, and mass customization driving change. The pallet changing systems of tomorrow will need to be more than just strong and fast; they will need to be intelligent, connected, and adaptable. For forward-thinking managers, investing in a system with an upgrade path to these technologies is a way to future-proof their operations. The question evolves from "How do I change pallets faster?" to "How can my material flow data make my entire plant smarter?"

Future trends in pallet changing technology are centered on IoT connectivity for predictive maintenance, advanced vision systems for autonomous quality checks during handling, and lightweight, adaptive grippers for mixed-model production, all contributing to the vision of the fully autonomous, self-optimizing factory. (future of automated material handling, smart pallet changer trends)

🤖 The Next Generation: Smart, Connected, and Flexible

Let's explore the innovations that will define the next decade of pallet handling:

-

📊 IoT & Predictive Analytics: Future pallet changers will be packed with sensors monitoring motor temperature, vibration, cycle counts, and clamp pressure. This data will stream to a cloud platform, enabling predictive maintenance. Instead of a sudden breakdown, you'll get an alert: "Axis 2 motor bearing shows early wear; schedule maintenance in 80 hours." This maximizes uptime and transforms maintenance from reactive to proactive.

-

👁️ Machine Vision Integration: Cameras integrated into the changer or the station will perform instant inspections during the transfer. Is the part seated correctly on the pallet? Is there visible damage from the previous process? The system can automatically reject a faulty load before it enters an expensive machining center, saving time and preventing tool damage.

-

🦾 Adaptive Gripping & Fixturing: As EV and custom vehicle production increases, lines must handle a wider variety of part geometries. We'll see more systems with quick-change adapters or even robotic grippers that can automatically reconfigure themselves to handle different pallet or tote styles within the same system, enabling true mixed-model flow without manual changeover.

-

🔗 Seamless MES/ERP Integration: The pallet changer will act as a critical data node. It will confirm job completion, update inventory in real-time as a pallet leaves a station, and provide cycle time data directly to the Manufacturing Execution System (MES) for live performance dashboards.

Staying ahead means partnering with suppliers who are investing in these technologies. While today you need a reliable rotary changer, choosing a supplier like Fengding that is developing these smart capabilities ensures your investment remains relevant and upgradeable as your factory evolves. This strategic foresight is what separates industry leaders from followers. (Industry 4.0 pallet handling, IoT in material handling systems)

Conclusion

Implementing the right pallet changing system is a strategic decision that directly addresses core automotive manufacturing challenges: downtime, safety, and quality. From selecting the optimal type to ensuring seamless integration, a thoughtful approach unlocks sustained gains in productivity and profitability. For a complete material handling solution, also explore our range of robust Pallet Inverter systems.