Check out the leading manufacturer for professional coil packing solutions here:

In today's rapidly evolving manufacturing industry, the demand for high-quality and efficient plastic injection machines is on the rise. One such innovative technology that has gained significant traction is 2k injection molding, also known as double injection molding, two-shot injection molding, or co-injection molding. This advanced technique allows for the production of complex plastic parts with multiple colors or materials in a single operation.

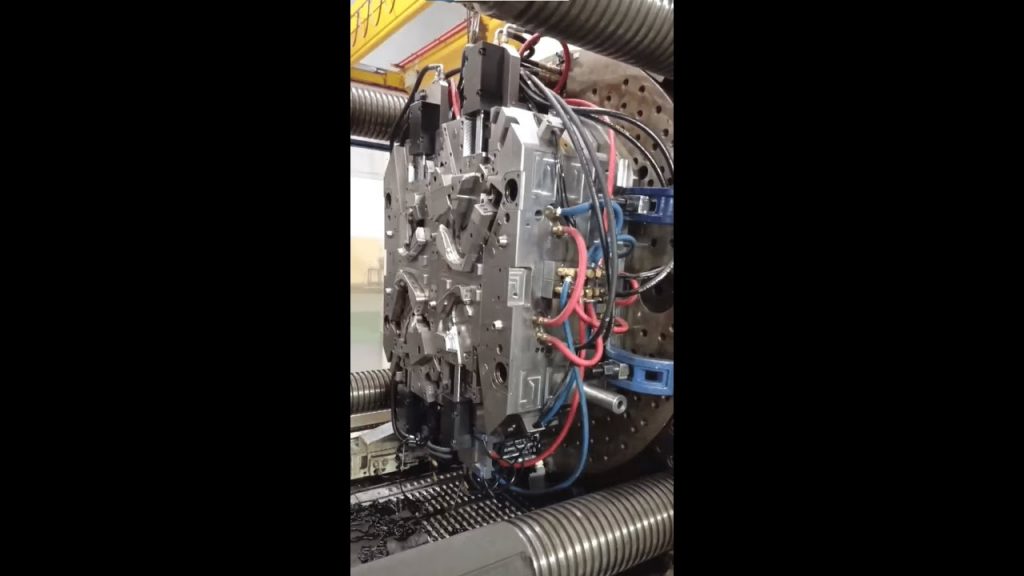

2k injection molding involves the use of a specialized machine capable of injecting two different materials into a single mold. The process begins with the injection of the first material, which forms the initial layer or base. Once the first material has solidified, the machine injects the second material, which bonds seamlessly with the first layer. The result is a finished product with exceptional durability, aesthetics, and functionality.

The advantages of 2k injection molding are numerous. Firstly, it eliminates the need for manual assembly or adhesive bonding of multiple components, reducing labor costs and improving production efficiency. Additionally, the process allows for the creation of intricate designs and textures that would otherwise be impossible or time-consuming to achieve. The ability to combine different materials also opens up new possibilities for enhanced product performance, such as combining rigid and flexible materials for optimal functionality.

Industrial plastic injection machines play a crucial role in the success of 2k injection molding. These machines are specifically designed to handle the unique requirements of the process, including precise control of injection speed, pressure, and temperature. The integration of advanced automation technologies further enhances the efficiency and reliability of the production process.

When considering an industrial plastic injection machine for 2k injection molding, it is essential to choose a reputable manufacturer that offers reliable and technologically advanced equipment. The machine should be capable of accommodating different mold sizes and configurations, providing flexibility to meet diverse production needs. Additionally, it should offer user-friendly controls and intuitive programming interfaces to streamline operation and reduce setup time.

At [Manufacturer Name], we specialize in providing top-of-the-line industrial plastic injection machines for 2k injection molding applications. Our machines are meticulously engineered to deliver exceptional performance, precision, and durability. With a strong focus on innovation and customer satisfaction, we are committed to meeting the evolving needs of the manufacturing industry.

In conclusion, 2k injection molding, or double injection molding, is a cutting-edge technology that enables the production of complex plastic parts with multiple colors or materials. Industrial plastic injection machines play a critical role in the success of this process, providing the necessary precision, control, and efficiency. When selecting an industrial plastic injection machine, it is essential to choose a reputable manufacturer that offers advanced technology and reliable equipment. Explore our range of industrial plastic injection machines for your 2k injection molding needs and experience the benefits of this innovative manufacturing technique. Plastic Injection Machine

"Mastering the Art of Advanced Injection Molding for Industrial Plastic Components: Unveiling the Secrets of Two Shot & Co-Injection Molding Techniques"