Check out the leading manufacturer for professional coil packing solutions here: [insert manufacturer's website URL].

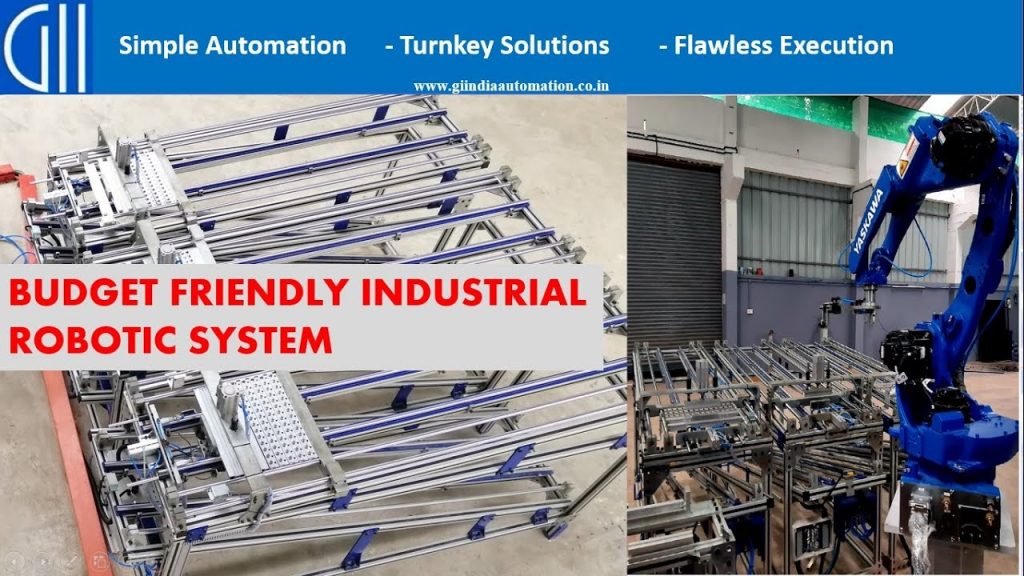

Title: GIIAS Introduces a Budget-Friendly Industrial Robotic System with Gravity Input/Output Conveyors

Introduction

In today's fast-paced industrial world, the demand for efficient and cost-effective automation solutions is on the rise. Industrial robots have become a crucial component in streamlining manufacturing processes, enhancing productivity, and reducing operational costs. GIIAS, a renowned name in the automation industry, has recently unveiled an innovative and budget-friendly industrial robotic system featuring gravity input/output conveyors. In this article, we will explore the capabilities of this cutting-edge system and its potential impact on various industries.

Opinion/Thought Piece Style

As a sales engineer, I have witnessed the transformative power of advanced robotics in the manufacturing sector. GIIAS' new industrial robotic system is no exception. By combining affordability with high-performance features, this system opens up new possibilities for businesses looking to optimize their operations without breaking the bank.

Case Study Style

Let's dive deeper into the capabilities of GIIAS' budget-friendly industrial robotic system. Equipped with Yaskawa robots, this system offers exceptional precision, reliability, and flexibility. The gravity input/output conveyors enable seamless material handling, significantly reducing manual labor and associated costs. Companies across diverse industries, such as automotive, electronics, and logistics, can benefit from this innovative solution.

Explanatory Style

The integration of gravity input/output conveyors in GIIAS' industrial robotic system is a game-changer. These conveyors utilize the force of gravity to move materials, eliminating the need for additional motors or power sources. This innovative approach not only simplifies the system but also reduces energy consumption, making it an environmentally friendly choice.

In-depth Analysis Style

GIIAS' budget-friendly industrial robotic system addresses a common challenge faced by many businesses – the high upfront costs of automation. By offering an affordable solution without compromising on quality, GIIAS aims to democratize automation technology. This system opens doors for small and medium-sized enterprises to embrace automation, empowering them to compete on a level playing field with larger players.

How-to Guide Style

If you are considering integrating an industrial robotic system into your operations, GIIAS' offering is worth exploring. Follow these steps to assess if this budget-friendly solution aligns with your requirements:

1. Evaluate your manufacturing processes and identify areas where automation can enhance efficiency and productivity.

2. Determine the specific tasks that the industrial robotic system needs to perform, such as material handling, assembly, or packaging.

3. Research and compare different automation solutions available in the market, considering factors like cost, performance, and reliability.

4. Contact GIIAS to learn more about their budget-friendly industrial robotic system and schedule a demonstration to witness its capabilities firsthand.

5. Analyze the potential return on investment and long-term benefits of implementing this system in your facility.

Conclusion

GIIAS' introduction of a budget-friendly industrial robotic system with gravity input/output conveyors showcases their commitment to making automation accessible to businesses of all sizes. This innovative solution, equipped with Yaskawa robots, offers exceptional precision, reliability, and flexibility. Whether you are in the automotive, electronics, or logistics industry, this system can revolutionize your manufacturing processes while keeping costs in check.

Check out the leading manufacturer for professional coil packing solutions here: [insert manufacturer's website URL]. Industrial Robot

"Affordable Industrial Robotic Solutions: Explore Cost-Effective Options for Your Business"