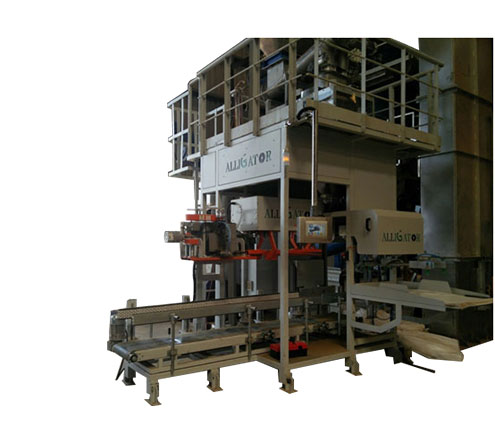

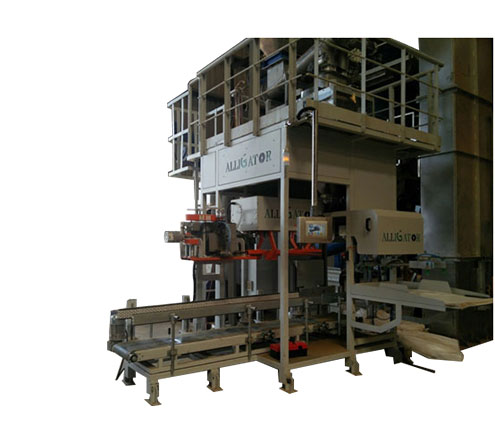

Automatic bagging machines can be a useful tool for businesses that handle a large volume of bagged products. By automating the process of bag placement and sealing, these machines can help increase efficiency and reduce the risk of errors.

There are several different types of automatic bagging machines available, each designed to handle specific types of products and packaging materials. Some common features of automatic bagging machines include:

- Bag placers: These units pick up bags and place them on a conveyor or packaging line, ready for filling.

- Auto-stitching units: These units use sewing machines or other sealing mechanisms to close the bags after they have been filled.

- Weighing systems: Many automatic bagging machines include scales or other weighing systems to ensure that the correct amount of product is being placed in each bag.

- Product feeders: These units feed product into the bagging machine, either manually or automatically, depending on the specific machine design.

By automating the bagging process, businesses can reduce the need for manual labor and increase the speed and accuracy of their packaging operations.