Choosing steel coil strapping machines for high-strength steel products

You’ve optimized your mill, streamlined your logistics, and your team is pushing hard. Yet, at the final hurdle—packing and shipping—bottlenecks appear. Manual strapping for high-strength steel coils is slow, inconsistent, and frankly, a safety gamble. Every minute of downtime or every coil damaged in transit chips away at your hard-earned margins and reputation. The pressure to ship faster, safer, and with perfect presentation is immense, especially when dealing with premium, high-tensile products bound for demanding industries. The wrong strapping machine isn't just an equipment failure; it's a direct threat to your operational integrity and customer trust.

The right steel coil strapping machine for high-strength products is one that matches the material's toughness with superior machine durability, applies consistent and calculable tension, and integrates seamlessly into your high-volume production line to eliminate bottlenecks and ensure damage-free transit. It’s not just about applying a strap; it’s about applying a guaranteed, repeatable seal of quality that survives the supply chain. For operations handling high-strength steel, the machine must be an industrial-grade partner, built to withstand the same rigorous environment as the coils it secures.

This decision is critical. A misstep can lock you into a cycle of repairs, inefficiency, and risk. But with the right framework, you can move from feeling overwhelmed to being strategically equipped. Let's break down the key questions you must ask to find a strapping solution that doesn't just work, but works as hard as your steel.

1. Why is machine durability the non-negotiable first factor for high-strength steel?

Imagine a machine failing mid-shift during a critical shipment. The line stops. Workers stand idle. The clock ticks on delivery deadlines. For factories processing high-strength steel, the operating environment itself is a test—constant vibration, airborne particulates, and the sheer physical demand of handling heavy coils. A standard-duty machine will quickly become the weakest link in your robust production chain. The first and most critical filter for any strapping equipment must be its ability to endure.

For high-strength steel coil packaging, machine durability is non-negotiable because the strapping system must operate reliably in the same harsh, high-demand environment as the mill itself. It needs a heavy-duty frame, industrial-grade components, and a design philosophy focused on maximum uptime, not just basic function. A fragile machine here is a constant source of cost, delay, and frustration.

🔩 Breaking Down Durability: The Three Pillars

Durability isn't a vague promise; it's a sum of specific, observable engineering choices. When evaluating a strapping machine, look beyond the sales sheet and inspect these three pillars.

Pillar 1: Structural Integrity & Frame Design

The machine's skeleton determines its lifespan.

- Heavy-Gauge Steel Construction: The frame should use thick, reinforced steel, not lightweight alloys. Tap it; it should feel solid, not hollow.

- Welded vs. Bolted: Look for critical joints that are fully welded for rigidity. Excessive bolting can lead to loosening under vibration.

- Vibration Dampening: High-quality machines often have isolated mounts for motors and gearboxes to prevent vibration from shaking the entire system apart.

| Feature | Low-Durability Machine | High-Durability Machine (e.g., Fengding) |

|---|---|---|

| Frame Material | Lightweight steel or aluminum | Reinforced, heavy-gauge steel plate |

| Critical Joints | Primarily bolted connections | Fully welded and reinforced key stress points |

| Component Mounting | Direct mounting to frame | Isolated mounts with dampeners |

Pillar 2: Critical Component Quality

The heart of the machine lies in its key moving parts.

- Strapping Head: This is the workhorse. It should be a sealed, self-contained unit designed for millions of cycles. Brands like Fengding often use proprietary, over-engineered heads known for longevity.

- Motors & Drives: Seek out branded, industrial-grade servo motors or gear motors. They offer precise control and are built for continuous operation, unlike cheaper, generic motors that overheat.

- Sealing & Protection: Look for IP (Ingress Protection) ratings. A rating of IP54 or higher indicates good protection against dust and water splash, which is essential in a mill environment.

Pillar 3: Design for Serviceability & Uptime

Even the best machines need maintenance. Durability includes how easily you can keep it running.

- Easy Access Panels: Can you reach common wear parts (seals, blades) in minutes without major disassembly?

- Modular Design: Are key components (like the strapping head) modular? This allows for swift replacement to minimize downtime, with the faulty unit being serviced off-line.

- Available Technical Support: True durability is backed by a supplier who provides comprehensive spare parts lists, detailed manuals, and responsive technical support. This is where a partner like Wuxi Buhui or our own FHOPEPACK network adds immense value beyond the initial sale.

Choosing a machine built on these three pillars means you're investing in a solution, not a recurring problem. It becomes a predictable asset, not a source of unpredictable downtime. (high-strength steel strapping, durable packaging equipment, mill-duty strapper)

2. How do tension control and sealing integrity prevent coil damage?

A loose strap is an invitation for disaster during transport. It allows the coil to shift, leading to edge damage, layer distortion, and potential unravelling. Conversely, excessive tension on a high-strength coil can itself deform the edge or, in worst-case scenarios, compromise the strap's integrity through over-stressing. The goal is a "Goldilocks" seal—perfectly tight, consistently applied, and securely locked every single time. This precision is what separates basic bundling from professional, damage-preventing packaging.

Proper tension control and sealing integrity prevent coil damage by applying a consistent, calibrated force that securely immobilizes the coil without crushing or distorting it. A robust heat-seal weld then creates a unified strap loop that maintains this tension throughout the violent shocks of logistics, preventing movement that causes edge wear, layer shift, and cosmetic flaws. It's the difference between a coil that arrives "factory-fresh" and one that requires rework or triggers a customer complaint.

🛡️ The Science of a Secure Seal: From Tension to Lock

Let's deconstruct the process to understand how a good machine guarantees a safe arrival.

Step 1: Precision Tensioning

This is where programmable logic is crucial.

- Adjustable & Repeatable: The machine should allow you to set a specific tension value (e.g., in kilograms or pounds). Once set, it must apply this exact tension to every coil, regardless of operator.

- Two-Stage Tensioning: Advanced systems often use a two-stage process. A quick take-up removes slack, followed by a slower, finer tensioning phase to reach the precise target. This prevents shock-loading the strap.

- Material-Specific Profiles: Can the machine save tension settings for different coil grades (e.g., a softer annealed coil vs. a spring-tempered coil)? This flexibility is key for mills with diverse product lines.

Step 2: The Critical Seal

The weld is the strap's weakest point—unless it's engineered to be its strongest.

- Heat-Seal vs. Friction Weld: For high-strength polypropylene or polyester straps, heat-seal (or thermal weld) is the industry standard for high-security applications. It melts the strap ends together, creating a weld that is often stronger than the strap body itself.

- Seal Integrity Checks: Some high-end machines incorporate a "seal check" cycle that briefly applies a reverse force to the weld to ensure it has properly set before release.

- Consistent Seal Quality: The temperature, pressure, and duration of the seal must be perfectly controlled. Variability here leads to weak seals that can snap under load.

Step 3: Preventing "Strap Bite" and Edge Damage

The point where the strap contacts the coil is a high-pressure zone.

- Strap Guidance Systems: Smooth, polished guides and feed channels ensure the strap lays flat against the coil without twisting. A twisted strap creates a thin, high-pressure edge that can dig into the steel.

- Protective Edge Guards: For the most sensitive finishes, the use of cardboard or polymer edge protectors under the strap is standard practice. An automated system may include a station to apply these before strapping.

Pro Tip from the Floor: A simple test is to check the first few strapped coils. The strap should be uniformly tight, lying flat against all surfaces, with a clean, smooth weld. There should be no visible indentation or "pinching" of the steel edge. If there is, your tension is too high or your guidance system is faulty.

By mastering tension and seal, you directly protect your product's value and your brand's reputation for quality. It turns packaging from a cost center into a quality assurance checkpoint. (steel coil tension control, strap sealing integrity, prevent edge damage)

3. What level of automation is right for your production volume and layout?

The spectrum ranges from a simple, manual-feed machine to a fully robotic, inline packaging cell. Throwing maximum automation at a low-volume line is a poor ROI. Sticking with manual labor on a high-volume line is a bottleneck and a safety hazard. The "right" level is the one that matches your output, eliminates your specific constraints, and provides a clear path to a positive return on investment. It's about solving your problem, not buying a generic "automation" label.

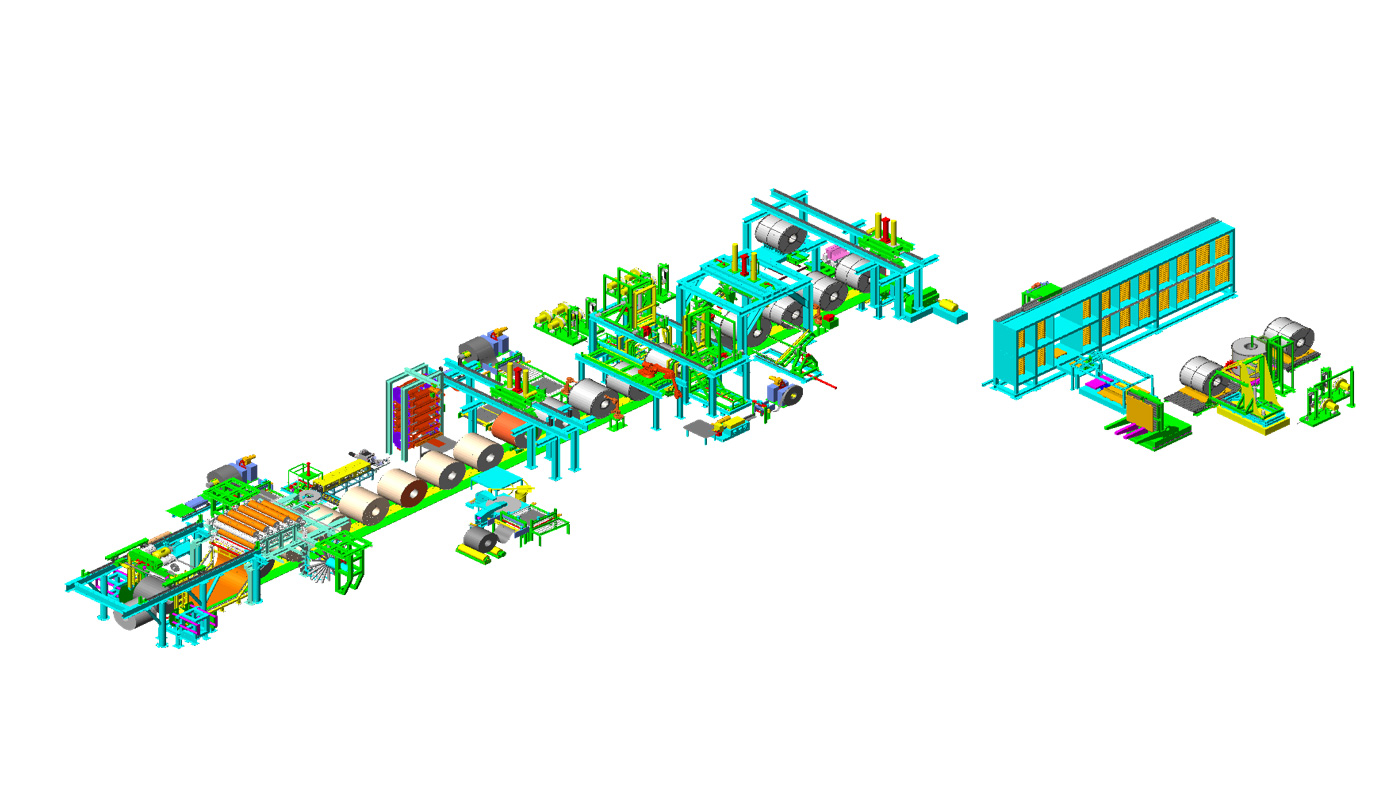

The right level of automation for your steel coil strapping is determined by a balance of your daily/weekly coil output, available floor space, labor costs, and required packing speed. For high-volume mills, a semi-automatic or fully automatic system with integrated conveyors is essential to maintain flow. For smaller or more varied production, a powered turntable or semi-automatic machine may offer the perfect balance of throughput boost and investment cost. The goal is to remove the bottleneck, not create a new, more expensive one.

🤖 Automation Tiers: Matching Solution to Scale

Here’s a breakdown of common configurations to help you identify your fit.

Tier 1: Semi-Automatic / Operator-Assisted

- Best For: Lower to medium volume, multiple coil sizes, operations with space constraints.

- How it Works: An operator positions the coil (often with a crane) onto a powered turntable. They initiate the cycle, and the machine automatically applies the strap(s) as the turntable rotates. The operator may need to feed the strap tail initially.

- Pros: Significant speed increase over fully manual strapping. Much safer, as the operator is away from the tensioning action. Lower initial investment.

- Cons: Still requires one dedicated operator. Throughput is limited by the operator's cycle time.

Tier 2: Fully Automatic (Inline)

- Best For: High-volume production with consistent coil sizes (e.g., a dedicated mill line).

- How it Works: The coil is conveyed automatically from the production line into the strapping station. Sensors detect its presence, position it, and the machine applies a pre-programmed strap pattern (e.g., 2 straps at 1/3 and 2/3 points) without human intervention. The coil then conveys out to the shipping area.

- Pros: Maximizes throughput, eliminates labor from the packing process, ensures perfect consistency. Ideal for 24/7 operations.

- Cons: Higher capital cost. Requires more integrated floor space and consistent upstream flow. Less flexible for wildly varying coil dimensions.

Tier 3: Robotic Integration

- Best For: Ultra-high-volume, advanced facilities where space is premium and flexibility is key, or where additional tasks (like applying tags or top protectors) are needed.

- How it Works: A robotic arm, often on a gantry, picks up a strapping head and moves to the coil. It can apply straps in complex patterns on stationary coils, adapting to different sizes on a mixed-flow line.

- Pros: Extreme flexibility, high density (saves floor space), can perform multiple packaging tasks.

- Cons: Highest cost and complexity. Requires sophisticated programming and maintenance.

Key Question for Your Team: What is the slowest part of your current pack-and-ship process? Is it the actual strapping, the positioning of the coil, or the application of protective materials? Your automation investment should target that specific bottleneck first.

4. How to evaluate a supplier as a true long-term partner?

The machine will arrive in a crate. The partnership, however, is what you'll rely on for the next decade. A supplier who disappears after the sale can leave you with a very expensive paperweight. For critical equipment like this, you're not just buying a product; you're entering a long-term relationship for parts, knowledge, and support. Your supplier's depth of industry experience and commitment to your success are as important as their machine's specifications.

Evaluate a strapping machine supplier as a long-term partner by scrutinizing their industry-specific experience, the depth of their after-sales support structure, and their willingness to provide tailored solutions rather than just off-the-shelf products. Look for case studies in metal processing, a clear spare parts policy, available remote diagnostics, and a proven track record of helping clients solve real production challenges. A true partner acts as an extension of your engineering team.

✅ The Partner Evaluation Checklist

Go beyond the sales visit. Ask these direct questions and demand evidence.

1. Industry Pedigree & Application Knowledge

- "How many of your machines are installed in steel mills or metal service centers?"

- "Can you share references or case studies from clients with products similar to my high-strength coils?"

- "Do your engineers have hands-on experience on the factory floor, or are they only design-room theorists?" (This is where my own journey from the factory floor to founding FHOPEPACK informs the practical advice I value and share.)

A supplier like Fengding has built its reputation specifically in heavy-industry packaging, which speaks volumes. Wuxi Buhui also has a strong focus on robust industrial applications.

2. Support Structure: From Installation to Overhaul

- Installation & Training: Is supervised installation and operator training included? Is it performed by factory engineers or local agents?

- Spare Parts Availability: What is the guaranteed lead time for critical spare parts? Do they stock a "wearing parts kit" for your machine model?

- Technical Support: Is there a direct phone/email line to technical engineers? Do they offer remote diagnostics via video call or data link?

- Service Network: Do they have trained service technicians in your region (e.g., Mexico/Latin America), or will support require international travel with long delays?

3. Solution Mindset vs. Product Salesman

- Listen First: A good partner will ask detailed questions about your process, pain points, and goals before recommending a machine.

- Customization Ability: Can they modify standard machines? For example, adding special guides for your coil ID, integrating with your specific conveyor height, or programming unique strap patterns?

- ROI Transparency: Will they help you build a realistic Return on Investment model based on your labor savings, reduced damage, and increased throughput?

The Red Flags: Vague answers on support, pressure to buy the most expensive model without justification, lack of client testimonials from your industry, and no commitment to post-sale documentation and training.

Choosing a partner like this transforms the purchase from a capital expense into a strategic investment in your operation's future reliability and growth. (strapping machine supplier evaluation, industrial packaging partner, after-sales support for packaging equipment)

Conclusion

Selecting the ideal steel coil strapping machine demands a focus on industrial durability, precise tension control, appropriate automation, and, crucially, a supplier who acts as a true partner. By prioritizing these factors, you secure not just a machine, but a reliable, profit-protecting solution for your high-strength steel products. For a range of robust solutions built for this exact challenge, explore the options from leading manufacturers like Steel Coil Strapping Machines.