Check out our selection of coil packing solutions from the leading manufacturers in the industry. We offer professional solutions for all your packaging needs. Whether you're in the automotive, electronics, or food and beverage industry, we have the perfect solution for you. Contact us today to learn more about our products and how we can help improve your packaging process.

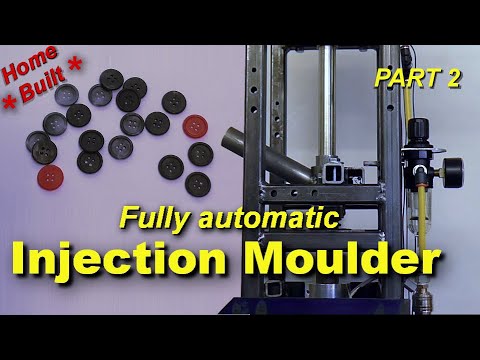

Title: Building the Injection Stage: Constructing the Injection Barrel, Piston, and Nozzle

Introduction:

Welcome back to our series on building a DIY injection molding machine. In this second part, we will focus on constructing the injection stage of the machine. We will delve into the details of building the injection barrel, piston, and nozzle, as well as incorporating some pneumatics. Additionally, we will conduct the first test of the machine to ensure its functionality. So, let's dive right in!

Section 1: Constructing the Injection Barrel, Piston, and Nozzle

The injection stage of a plastic injection machine plays a crucial role in the entire molding process. It is responsible for melting the plastic material and injecting it into the mold cavity. To construct the injection barrel, we need to select a high-quality steel tube with the appropriate dimensions. It should be able to withstand the high temperatures and pressures involved in the injection molding process.

Next, we need to design and build the piston that will push the molten plastic material into the barrel. The piston should be made of a durable and heat-resistant material to prevent any deformation or damage during the injection process. We also need to ensure that the piston fits snugly within the barrel to maintain a proper seal.

The nozzle is another crucial component of the injection stage. It is responsible for delivering the molten plastic material from the barrel into the mold cavity. The nozzle should be carefully designed to provide a controlled flow of plastic material and prevent any leakage or wastage. It must also be easily detachable for maintenance and cleaning purposes.

Section 2: Incorporating Pneumatics

In addition to the construction of the injection barrel, piston, and nozzle, we also need to incorporate some pneumatics into our DIY injection molding machine. Pneumatics play a vital role in controlling the movement and pressure of the injection stage.

By utilizing pneumatic cylinders, we can control the speed and force of the piston during the injection process. This allows for precise control over the amount of plastic material injected into the mold cavity, resulting in high-quality molded products. Pneumatic valves are also used to regulate the flow of compressed air, ensuring smooth operation of the machine.

Section 3: First Test of the Injection Stage

After completing the construction of the injection stage and incorporating the necessary pneumatics, it's time for the first test of our DIY injection molding machine. This test is crucial to ensure that all components are functioning correctly and that the machine can effectively melt and inject plastic material into the mold cavity.

During the test, we will monitor the temperature and pressure within the injection barrel to ensure they are within the desired range. We will also observe the movement of the piston and the flow of plastic material through the nozzle. Any issues or abnormalities detected during the test will be addressed and rectified to ensure optimal performance of the machine.

Conclusion:

In this article, we have explored the construction of the injection stage of a DIY injection molding machine. We have discussed the importance of building a high-quality injection barrel, piston, and nozzle, as well as incorporating pneumatics for precise control. By conducting the first test, we can ensure that our machine is ready for the injection molding process. Stay tuned for the next part of our series, where we will delve into other essential components of the DIY injection molding machine.

Check out our selection of high-quality plastic injection machines for all your molding needs. We offer professional solutions that guarantee efficiency and reliability. Contact us today to learn more about our products and how they can enhance your manufacturing process. Plastic Injection Machine

"Improving DIY Injection Moulding: Advanced Techniques for Enhanced Plastic Injection Machine"