Robots Are Designed Based on Work Envelope Requirements: Understanding Industrial Robotic Arms

Introduction:

In today's rapidly advancing technological landscape, industrial robotic arms have become an integral part of many manufacturing processes. These sophisticated machines are designed to perform repetitive tasks with precision and efficiency. One crucial aspect of designing these robots is determining their work envelope, which refers to the volume that the end effector of the robot is able to reach. In this article, we will explore the concept of work envelopes in industrial robotic arms and shed light on their importance in optimizing manufacturing operations.

Understanding Work Envelopes:

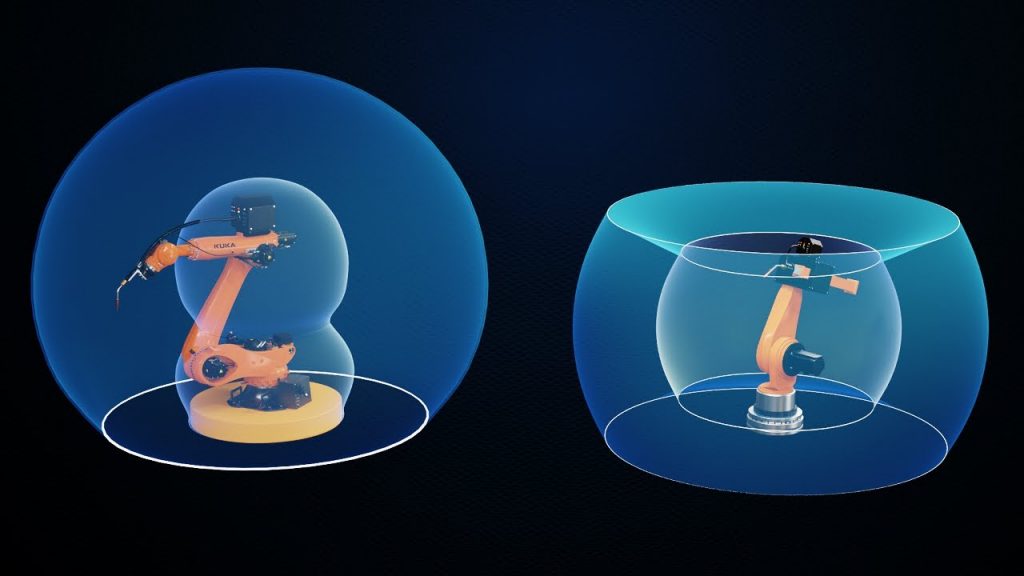

The work envelope of an industrial robotic arm is essentially the three-dimensional space it can operate within. It is defined by the range of motion of the robot's various joints and the length of its arms. By understanding the work envelope, manufacturers can determine how far the robot's end effector can reach and what areas it can access. This information is crucial when designing a robotics system to ensure that it can perform the desired tasks effectively.

Designing Robots for Specific Work Envelopes:

Industrial robotic arms are not one-size-fits-all machines. They are designed based on the specific work envelope requirements of the manufacturing process they will be involved in. Factors such as the size and shape of the products being handled, the layout of the production line, and the desired range of motion all play a role in determining the work envelope of a robot.

To optimize the performance of a robotic arm, engineers must carefully analyze the work envelope requirements of the production process. By considering factors such as the height, reach, and payload capacity needed, they can design a robot that can efficiently handle the tasks at hand. This ensures that the robot can access all the necessary areas and perform its duties without any limitations.

Maximizing Efficiency with Work Envelopes:

By accurately designing industrial robotic arms based on their work envelope requirements, manufacturers can maximize efficiency and productivity in their operations. A well-designed robot can perform tasks in tight spaces, reach high shelves, and cover a large area without the need for human intervention. This not only reduces the risk of accidents and injuries but also allows for faster and more consistent production rates.

Furthermore, understanding the work envelope of a robotic arm enables manufacturers to optimize the layout of their production lines. By strategically placing robots with complementary work envelopes, they can minimize bottlenecks and ensure a smooth workflow. This leads to increased throughput, reduced downtime, and ultimately, improved profitability.

Conclusion:

Industrial robotic arms are revolutionizing the manufacturing industry, and their design plays a crucial role in their effectiveness. By understanding the concept of work envelopes and designing robots accordingly, manufacturers can unleash the full potential of these machines. Optimized work envelopes lead to increased efficiency, improved safety, and higher productivity. So, if you're looking to enhance your manufacturing processes, make sure to consider the work envelope requirements when selecting an industrial robotic arm.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

"Exploring the Mechanisms Behind Industrial Robotic Arms: Unveiling the Work Envelopes and Functions"