Title: Advanced Automatic Packaging Line for Detergent Powder - Efficient and Reliable Solution | YouTube SEO Optimized Video Description

Description:

Introduction:

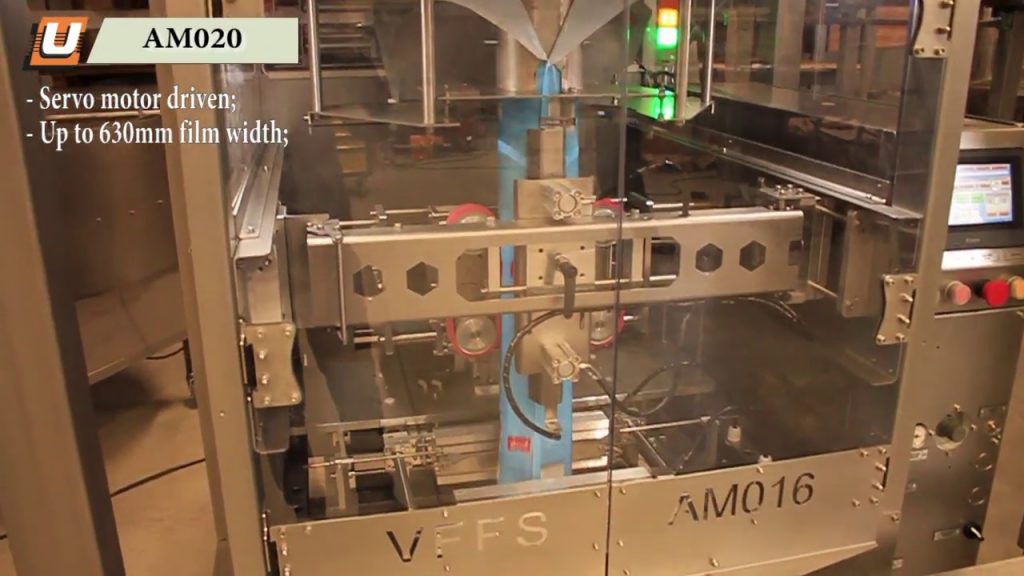

Welcome to our YouTube video showcasing the cutting-edge Automatic Packing Line for Detergent Powder, designed and manufactured by industry-leading Automatic Packing Line Manufacturers. In this video, we present the AM020-ATD04P & VFFS machine AM020, equipped with a 4-head linear weigher ATD04-P, specifically engineered for the seamless packaging of detergent powders. Prepare to be amazed by the exceptional features and benefits of this advanced packaging solution.

Video Content:

Our Automatic Packaging Line for Detergent Powder AM020-ATD04P & VFFS machine AM020 is a game-changer in the industry, revolutionizing the packaging process for detergent powders. This high-performance system combines precision, speed, and efficiency to deliver outstanding results for your packaging needs.

Key Highlights:

1. Unparalleled Efficiency: The Automatic Packaging Line utilizes advanced technology to streamline the packaging process, maximizing productivity and reducing downtime. It ensures consistent and accurate weighing, filling, and sealing of detergent powders, resulting in increased output and minimized wastage.

2. Versatile Packaging Solution: Designed to cater to various packaging requirements, the Automatic Packaging Line can handle a wide range of packaging materials and sizes, providing flexibility and adaptability for different product specifications.

3. Precise Weighing System: Equipped with a 4-head linear weigher ATD04-P, this line ensures precise measurement and distribution of detergent powders, guaranteeing uniformity in each package. This feature eliminates inconsistencies and ensures customer satisfaction.

4. Advanced VFFS Machine: The VFFS (Vertical Form Fill Seal) machine AM020 is an integral part of the packaging line, enabling efficient packaging by forming, filling, and sealing the detergent powder packets quickly and accurately. Its user-friendly interface allows for easy operation and maintenance.

5. Enhanced Product Safety: Our packaging line adheres to the highest quality standards, ensuring the safety and integrity of your detergent powder products. It incorporates advanced sealing mechanisms, preventing contamination and preserving the freshness of the powders.

Operation Steps:

1. Loading: The detergent powder is loaded into the hopper of the Automatic Packaging Line.

2. Weighing and Distribution: The 4-head linear weigher ATD04-P accurately measures the desired quantity of detergent powder and distributes it into individual packages.

3. Forming and Filling: The VFFS machine AM020 forms the packaging material into pouches or bags, fills them with the measured detergent powder, and seals them.

4. Sealing and Packaging: The sealed detergent powder packages are then discharged from the VFFS machine, ready for distribution and retail.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with others who might benefit from this innovative Automatic Packing Line for Detergent Powder. For more updates and similar content, subscribe to our channel and stay tuned for the latest advancements in packaging technology.

Additional Tags and Keywords: Automatic Packing Line, Automatic Packaging Line, Detergent Powder Packaging, Advanced Packaging Solution, Linear Weigher, VFFS Machine, Packaging Efficiency, Product Safety, Manufacturing Industry, Packaging Technology.

Hashtags: #AutomaticPackingLine #DetergentPowderPackaging #AdvancedPackagingSolution #LinearWeigher #VFFSMachine #PackagingEfficiency #ProductSafety #ManufacturingIndustry #PackagingTechnology

Here is a sample tilter for an Automatic Packaging Line for Detergent Powder AM020-ATD04P:

Title: Automatic Packaging Line Tilter for Detergent Powder AM020-ATD04P

1. Introduction:

The Automatic Packaging Line Tilter for Detergent Powder AM020-ATD04P is designed to automate the packaging process of detergent powder. This tilter ensures efficient and accurate packaging by automatically tilting the detergent powder containers to facilitate easy and smooth filling. In this document, we will outline the specifications, features, and benefits of the tilter, along with its operating principles and safety measures.

2. Specifications:

- Model: AM020-ATD04P

- Maximum container weight: 20kg

- Tilting angle range: 0-90 degrees

- Tilting speed: Adjustable from 0 to 30 degrees per second

- Control system: PLC-based with touch screen interface

- Power supply: 220V, 50Hz, 3-phase

- Material: Stainless steel for enhanced durability and hygiene

- Dimensions: (L) 1500mm x (W) 1000mm x (H) 2000mm

- Weight: 500kg

3. Features and Benefits:

- Automated tilting: The tilter eliminates the need for manual tilting of detergent powder containers, reducing labor costs and improving productivity.

- Adjustable tilting speed: The tilting speed can be customized according to the specific requirements of the packaging line, ensuring optimal efficiency.

- Wide tilting angle range: The tilter can tilt containers from 0 to 90 degrees, accommodating various container sizes and shapes.

- Precise control system: The PLC-based control system allows for precise and accurate tilting, ensuring consistent and uniform filling of the containers.

- User-friendly interface: The touch screen interface provides operators with an intuitive and easy-to-use platform for controlling and monitoring the tilter.

- Robust construction: The tilter is built with stainless steel, making it resistant to corrosion and suitable for hygienic environments.

- Safety features: The tilter is equipped with safety sensors and emergency stop buttons to ensure operator safety during operation.

4. Operating Principles:

- The operator places the detergent powder containers onto the tilter platform.

- The operator selects the desired tilting angle and speed through the touch screen interface.

- Upon receiving the command, the tilter starts tilting the containers at the specified speed.

- Once the containers reach the desired angle, the tilter stops automatically.

- The tilted containers are then ready for the filling process in the packaging line.

5. Safety Measures:

- Emergency stop buttons are strategically placed near the tilter for immediate shutdown in case of any unforeseen circumstances.

- Safety sensors are integrated to detect any obstructions or anomalies during the tilting process, halting the operation if necessary.

- Adequate training and safety guidelines should be provided to operators to ensure safe operation and maintenance of the tilter.

Note: This is a general tilter description for an Automatic Packaging Line for Detergent Powder AM020-ATD04P. The actual tilter may have additional or specific features depending on the manufacturer and customer requirements. Automatic Packing Line

#Automatic #Packaging #Line #Detergent #Powder #AM020ATD04P