Check out the leading manufacturer for professional coil packing solutions here:

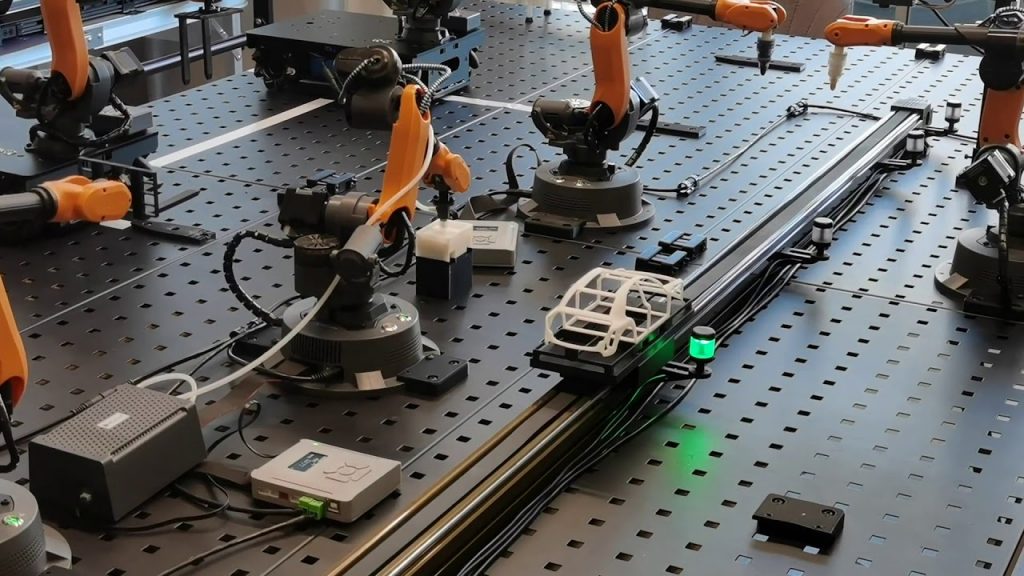

The rise of automation in various industries has revolutionized the way products are manufactured. One such industry that has greatly benefited from automation is the automobile production line. With technological advancements, robots have become an integral part of the production process, enhancing efficiency and productivity. WLKATA, a renowned name in the field of robotics, has introduced the Mirobot Automobile Production Line, equipped with its state-of-the-art Mirobot robotic arm. In this article, we will delve into the capabilities of this innovative robotic arm and explore its role in the automotive industry.

The WLKATA Mirobot Automobile Production Line offers a comprehensive solution for automotive manufacturers seeking to streamline their production process. This robotic arm is designed to perform a wide range of tasks, from material handling and assembly to welding and painting. Its versatility makes it an ideal choice for automakers looking to optimize their operations.

One of the key advantages of the Mirobot robotic arm is its flexibility. It can be easily programmed to perform complex tasks with precision and accuracy. This allows manufacturers to adapt to changing production requirements without the need for extensive reprogramming or retooling. With its advanced sensors and intelligent control system, the Mirobot arm can seamlessly integrate into existing production lines, minimizing downtime and maximizing efficiency.

In terms of performance, the Mirobot robotic arm excels in speed and accuracy. It can perform tasks at a rapid pace, significantly reducing cycle times and increasing overall productivity. The arm's high payload capacity enables it to handle heavy components with ease, making it suitable for a wide range of automotive applications. Its precise motion control ensures that every task is executed with utmost precision, minimizing errors and improving product quality.

When it comes to the cost, the Mirobot robotic arm offers excellent value for money. Compared to traditional industrial robots, it is competitively priced, making it an affordable choice for small and medium-sized automotive manufacturers. The initial investment in the Mirobot arm is quickly recouped through improved productivity and reduced labor costs. Moreover, WLKATA provides comprehensive after-sales support, ensuring that customers get the most out of their investment.

The Mirobot robotic arm is just one example of the advancements in industrial robotics that have transformed the automotive industry. As automation continues to evolve, manufacturers can expect further improvements in efficiency, quality, and cost-effectiveness. The integration of robotics in the automobile production line has not only enhanced productivity but also improved worker safety by eliminating hazardous tasks.

In conclusion, the WLKATA Mirobot Automobile Production Line, equipped with the Mirobot robotic arm, is a game-changer for the automotive industry. Its flexibility, performance, and affordability make it an attractive choice for automakers seeking to optimize their production process. As automation continues to shape the future of manufacturing, investing in advanced robotic solutions like the Mirobot arm is essential for staying competitive in the market.

Check out the leading manufacturer for professional coil packing solutions here: Industrial Robot

"Enhancing Efficiency and Cost-effectiveness: Exploring the Revolutionary WLKATA Mirobot for Automobile Production Lines"