Introduction to the Engine Oil Bottle Blow Molding Machine: Efficient Production and Automatic Trimming

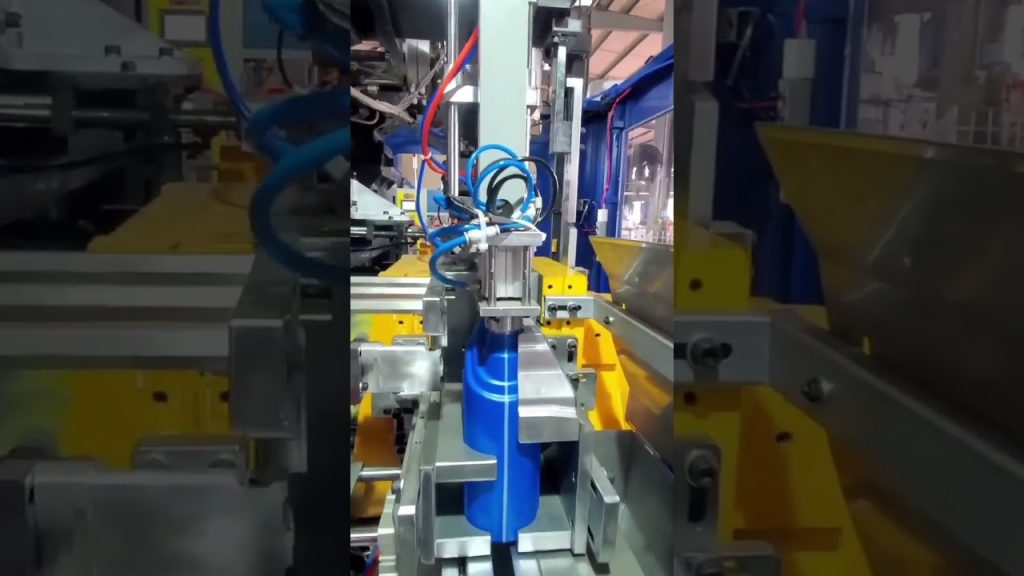

In the fast-paced world of manufacturing, efficiency and automation are key factors in ensuring smooth operations and cost-effective production. One such innovation that has revolutionized the production of engine oil bottles is the Engine Oil Bottle Blow Molding Machine. This powerful machine combines the capabilities of an Automatic Plastic Injection Machine and a Blow Molding Machine, enabling manufacturers to produce high-quality bottles with ease.

The Engine Oil Bottle Blow Molding Machine is specifically designed to cater to the needs of the engine oil industry. It is equipped with advanced features that streamline the production process and ensure consistent output. With its automatic plastic injection capabilities, the machine precisely molds the plastic material into the desired shape, resulting in uniform and durable bottles.

The machine's powerful blow molding technology takes the production process a step further. It blows compressed air into the molded plastic, expanding it to create the final bottle shape. This ensures that the bottles have the required strength and thickness to withstand the demands of the engine oil industry.

One of the key advantages of the Engine Oil Bottle Blow Molding Machine is its automatic trimming feature. After the bottles are formed, the machine automatically trims off any excess plastic, resulting in a clean and polished finish. This eliminates the need for manual trimming, saving both time and labor costs.

With its efficient production capabilities, the Engine Oil Bottle Blow Molding Machine is capable of producing a large number of bottles in a short period of time. This is particularly advantageous for manufacturers who face high demand and need to meet tight production deadlines.

Furthermore, the machine's automatic operation reduces the risk of human error, ensuring consistent quality in every bottle produced. This not only enhances customer satisfaction but also helps manufacturers maintain a strong reputation in the market.

To ensure optimal performance, it is crucial to choose a reliable and experienced manufacturer for the Engine Oil Bottle Blow Molding Machine. Leading manufacturers in the industry offer comprehensive solutions and support, including installation, training, and after-sales service. They also provide customization options to meet specific production requirements.

In conclusion, the Engine Oil Bottle Blow Molding Machine is a game-changer in the production of engine oil bottles. Its combination of an Automatic Plastic Injection Machine and a powerful Blow Molding Machine enables efficient production, automatic trimming, and consistent quality. By choosing a reputable manufacturer, manufacturers can take advantage of this innovative technology to streamline their operations and stay ahead in the competitive market.

Check out leading manufacturers to explore the professional solution for your coil packing needs and ensure efficient and reliable packaging. Plastic Injection Machine

"Efficient Production of Powerful Blow Molding Machine: Automatic Trimming & Injection for Engine Oil Bottles"