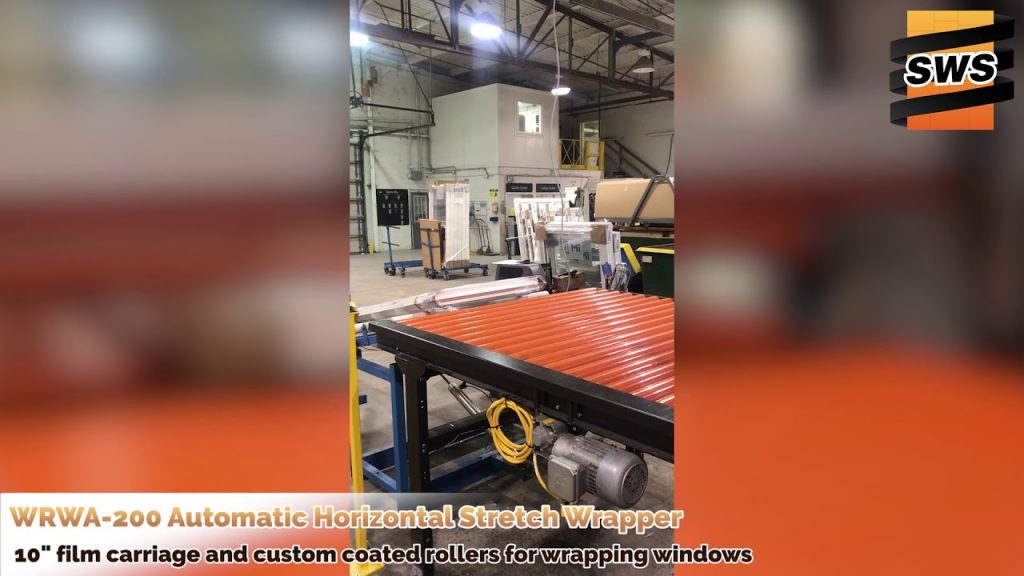

Title: Automatic Orbital Stretch Wrapper - Wulftec WRWA-200 Horizontal Ring Stretch Wrapper Installation by SWS Technicians

Description:

Introduction:

Welcome to our video featuring the installation of the Wulftec WRWA-200 Automatic Horizontal Ring Stretch Wrapper by our skilled technicians, John and Matt. In this video, we highlight the key features and benefits of the Automatic Orbital Stretch Wrapper, providing valuable insights for businesses seeking efficient packaging solutions.

Video Content:

Our expert technicians, John and Matt, recently installed the Wulftec WRWA-200 Automatic Horizontal Ring Stretch Wrapper for a valued client. This state-of-the-art stretch wrapping machine offers exceptional capabilities in optimizing packaging processes. With its advanced technology and precise operation, the Wulftec WRWA-200 ensures secure and cost-effective wrapping of various products, streamlining workflow and enhancing productivity.

Key Highlights:

- Efficient Operation: The Wulftec WRWA-200 boasts an automated orbital wrapping mechanism, providing consistent and reliable wrapping results. Its horizontal ring design allows for seamless integration into existing production lines, ensuring smooth operations and minimal downtime.

- Versatile Wrapping Options: This stretch wrapper accommodates a wide range of product sizes and shapes, making it suitable for diverse industries such as food and beverage, logistics, and manufacturing. Its flexibility allows for customized wrapping patterns, providing optimal protection for your products during transportation and storage.

- User-Friendly Interface: Equipped with an intuitive control panel, the Wulftec WRWA-200 enables easy programming and adjustment of wrapping parameters. Its user-friendly interface ensures hassle-free operation, reducing the need for extensive training and maximizing efficiency.

Operation Steps:

1. Preparation: Set up the Wulftec WRWA-200 by adjusting the necessary settings such as wrapping speed, tension, and film overlap.

2. Product Loading: Place your products onto the conveyor, ensuring proper alignment for consistent wrapping results.

3. Wrapping Process: Activate the machine and observe as the Wulftec WRWA-200 applies the stretch film around your products, securely sealing them in a protective layer.

4. Completion: Once the wrapping cycle is finished, the machine will automatically cut the film and release the wrapped products for further processing or shipment.

Call to Action:

If you found this video informative and valuable, please consider liking, subscribing, and sharing it with others who may benefit from learning about the Automatic Orbital Stretch Wrapper. Stay tuned for more insightful videos from our channel to enhance your understanding of packaging solutions and machinery.

Additional Tags and Keywords:

Automatic Orbital Stretch Wrapper, Wulftec WRWA-200, Horizontal Stretch Wrapper, Packaging Solutions, Efficient Wrapping, Productivity Enhancement, Streamlined Operations, Versatile Wrapping Patterns, User-Friendly Interface, Secure Packaging, Customized Wrapping, Cost-Effective Solutions, Logistics, Manufacturing, Food and Beverage, Enhanced Product Protection.

Hashtags:

#AutomaticOrbitalStretchWrapper #WulftecWRWA200 #HorizontalStretchWrapper #PackagingSolutions #ProductivityEnhancement #SecurePackaging #CustomizedWrapping #Logistics #Manufacturing #ProductProtection

Sure! Here's a sample tilter for the Wulftec WRWA-200 Automatic Horizontal Stretch Wrapper:

Title: Wulftec WRWA-200 Automatic Horizontal Stretch Wrapper: Efficient and Reliable Tilter Solution

Introduction:

The Wulftec WRWA-200 Automatic Horizontal Stretch Wrapper is a state-of-the-art machine designed to streamline the packaging process for various industries. However, to further enhance its capabilities, a tilter can be incorporated into the system. In this article, we will explore the benefits and features of adding a tilter to the Wulftec WRWA-200, highlighting its efficiency and reliability.

1. Increased Flexibility:

By integrating a tilter into the Wulftec WRWA-200, businesses can achieve greater flexibility in their packaging operations. The tilter allows for easy repositioning of the pallet load, enabling the stretch wrapper to accommodate a wider range of load sizes and shapes. This flexibility ensures that the machine can handle diverse packaging requirements, maximizing efficiency and reducing downtime.

2. Enhanced Load Stability:

The tilter feature plays a crucial role in ensuring load stability during the wrapping process. It allows for precise positioning of the load, ensuring that it is securely positioned on the pallet before the stretch film is applied. This eliminates the risk of product damage or shifting during transit, providing peace of mind to manufacturers and customers alike.

3. Time and Labor Savings:

Integrating a tilter with the Wulftec WRWA-200 automates the load repositioning process, minimizing the need for manual labor. With the touch of a button, the tilter adjusts the load angle, eliminating the need for workers to physically reposition the load. This not only saves time but also reduces the risk of injuries associated with manual load handling, contributing to a safer working environment.

4. Improved Ergonomics:

Ergonomics is a critical consideration in any packaging facility. The tilter feature of the Wulftec WRWA-200 enhances ergonomics by reducing the strain on workers' bodies. By eliminating the need for manual load handling and repositioning, the tilter promotes a more comfortable and efficient working environment, ultimately boosting productivity.

5. Integration and Compatibility:

The tilter can be seamlessly integrated into the existing Wulftec WRWA-200 system, ensuring compatibility and easy implementation. Its user-friendly interface allows operators to adjust the tilt angle and control the tilter's functions with ease. Additionally, the tilter is designed with durability in mind, ensuring reliable performance even in demanding industrial environments.

Conclusion:

The addition of a tilter to the Wulftec WRWA-200 Automatic Horizontal Stretch Wrapper offers numerous benefits to businesses. From increased flexibility and load stability to time and labor savings, this tilter solution enhances the overall efficiency and reliability of the packaging process. By considering the integration of a tilter, companies can optimize their operations and gain a competitive edge in the market.Orbital Stretch Wrapper

#Wulftec #WRWA200 #Automatic #Horizontal #Stretch #Wrapper