"Check out the leading manufacturer for professional coil packing solutions right here."

Strapping Machine Repair: Ensuring Efficient Operations with the Eagle 800 Automatic Strapping System

Introduction:

In today's fast-paced manufacturing industry, businesses rely heavily on efficient packaging processes to meet the growing demand for products. Strapping machines play a crucial role in ensuring secure packaging, improving productivity, and minimizing downtime. However, like any other machinery, strapping machines may encounter issues that require professional repair services. In this article, we will explore the importance of strapping machine repair and highlight the benefits of the Eagle 800 Automatic Strapping System.

The Significance of Strapping Machine Repair:

1. Minimizing Downtime:

Downtime can be detrimental to any manufacturing operation, leading to delays, decreased productivity, and potential financial losses. By investing in regular strapping machine repair, you can minimize unexpected breakdowns and ensure that your operations run smoothly.

2. Extending Machine Lifespan:

Regular maintenance and timely repairs can significantly extend the lifespan of your strapping machines. Investing in repair services not only saves you money in the long run but also ensures that your machines operate at their optimal performance levels.

3. Enhancing Efficiency:

A well-maintained strapping machine operates efficiently, resulting in higher productivity levels. By addressing any issues promptly, you can prevent bottlenecks in your packaging process and maintain a seamless workflow.

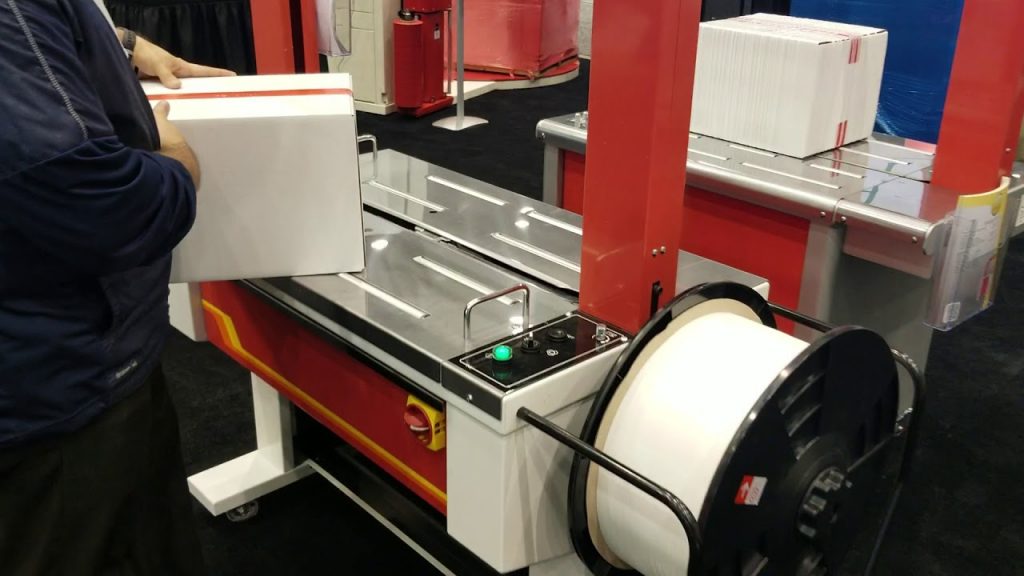

The Eagle 800 Automatic Strapping System: An Overview:

The Eagle 800 Automatic Strapping System is a cutting-edge solution designed to meet the demands of modern manufacturing environments. With its advanced features and robust construction, it offers several benefits for businesses in need of reliable and efficient strapping equipment.

1. Speed and Accuracy:

The Eagle 800 boasts a high strapping speed, ensuring that your packaging process remains efficient and time-effective. Its precise control system guarantees accurate strapping, eliminating the risk of improper or weak packaging.

2. Versatility:

This strapping system is highly versatile, accommodating a wide range of products, regardless of their size or shape. Whether you need to secure small packages or bundle larger items, the Eagle 800 can handle it all with ease.

3. Durability:

Manufactured using durable materials, the Eagle 800 is built to withstand the rigors of continuous operation. Its robust construction ensures longevity, reducing the need for frequent repairs and replacements.

4. User-Friendly Interface:

With a user-friendly interface, the Eagle 800 is easy to operate, even for employees with minimal technical expertise. Its intuitive controls and clear instructions make it a hassle-free addition to your packaging line.

Conclusion:

Strapping machine repair is a critical aspect of maintaining a smooth and efficient packaging process. By investing in professional repair services, businesses can minimize downtime, extend machine lifespan, and enhance overall efficiency. The Eagle 800 Automatic Strapping System stands out as a reliable solution that offers speed, accuracy, versatility, and durability.

If you are in need of strapping machine repair services or are interested in exploring the capabilities of the Eagle 800, reach out to us today. Our team of experts is ready to assist you in finding the perfect strapping solution for your specific needs.

Check out the leading manufacturer for professional coil packing solutions right here. Strapping Machines

"Efficient and Reliable Strapping System Repair: Enhance Productivity with the Eagle 800 Automatic Strapping Machine"