Title:

Automated Packing Systems and Automatic Plastic Bottle Capping Machine - Enhancing Efficiency and Precision

Description:

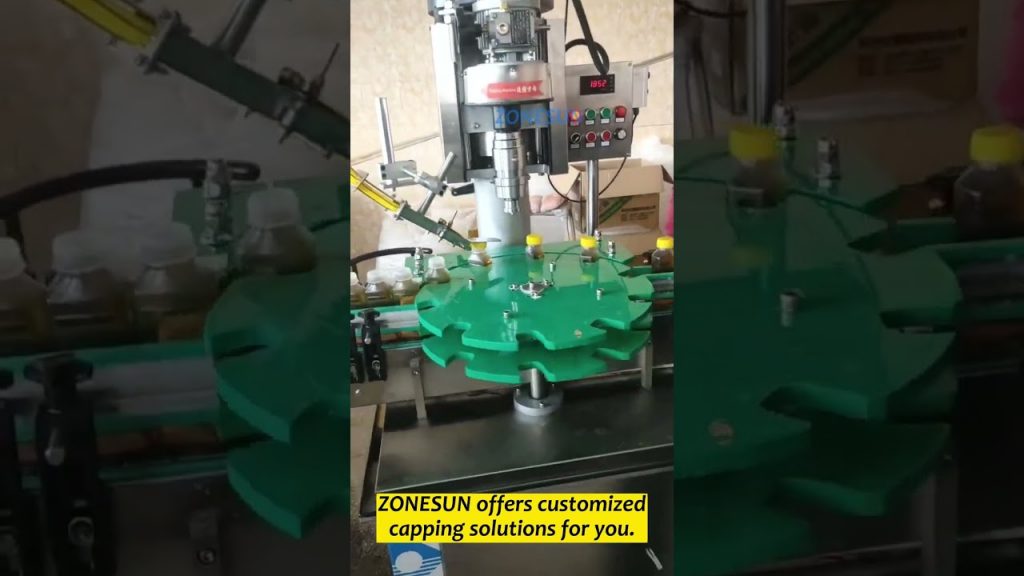

Welcome to our YouTube video showcasing the cutting-edge technology of Automated Packing Systems and the remarkable capabilities of the Automatic Plastic Bottle Capping Machine. This state-of-the-art capping machine is designed to streamline the packaging process by automating the feeding and tightening of caps, resulting in improved efficiency and productivity. With a capping speed of 20-30 bottles per minute, this machine is a game-changer for businesses in need of high-volume production.

Introduction:

In this video, we dive into the world of Automated Packing Systems and explore the incredible features of the Automatic Plastic Bottle Capping Machine. We will provide you with an in-depth understanding of how this machine works, its exceptional capabilities, and the significant benefits it brings to various industries.

Video Content:

1. Overview of Automated Packing Systems:

- Introduction to the concept and benefits of automated packing systems.

- Explanation of how these systems optimize the packaging process, ensuring accuracy and consistency.

- Examples of industries that can benefit from implementing automated packing systems.

2. Introduction to the Automatic Plastic Bottle Capping Machine:

- Detailed description of the machine's functionalities, including automatic cap feeding and tightening.

- Highlighting the capping speed of 20-30 bottles per minute, significantly reducing manual labor and time consumption.

- Demonstration of the machine's precise and reliable performance, ensuring consistent cap application.

3. Key Features and Advantages:

- Overview of the machine's features, such as adjustable cap torque, user-friendly controls, and easy maintenance.

- Discussion on how this machine enhances production efficiency by reducing errors and increasing output.

- Benefits of using an automated capping machine, including improved product quality, reduced labor costs, and enhanced customer satisfaction.

4. Operation Steps:

- Step-by-step guide on how to operate the Automatic Plastic Bottle Capping Machine, ensuring seamless integration into your production line.

- Detailed explanation of each step, from preparing the machine for operation to troubleshooting common issues.

Call to Action:

If you found this video informative and valuable, please give it a thumbs up and subscribe to our channel for more insightful content. Don't forget to share this video with others who might benefit from the knowledge shared here.

Additional Tags and Keywords:

Automated Packing Systems, Automatic Plastic Bottle Capping Machine, packaging automation, capping machine, cap feeding, cap tightening, high-speed capping, production efficiency, precision packaging, industrial automation.

Hashtags:

#AutomatedPackingSystems #CappingMachine #PackagingAutomation #ProductivityEnhancement #IndustrialAutomation

Sure! Here's a sample code for a tilt sensor that can be used with an Automatic Plastic Bottle Capping Machine:

```python

import RPi.GPIO as GPIO

import time

# Set up GPIO pin for tilt sensor

tilt_pin = 17

GPIO.setmode(GPIO.BCM)

GPIO.setup(tilt_pin, GPIO.IN, pull_up_down=GPIO.PUD_UP)

# Function to be called when the tilt sensor is triggered

def tilt_callback(channel):

print("Bottle tilted!")

# Perform necessary actions for capping machine when bottle is tilted

# Add event detection for the tilt sensor

GPIO.add_event_detect(tilt_pin, GPIO.RISING, callback=tilt_callback, bouncetime=300)

try:

while True:

# Keep the program running

time.sleep(1)

except KeyboardInterrupt:

print("Program stopped by user")

GPIO.cleanup()

```

In this code, the tilt sensor is connected to GPIO pin 17 (you can change it according to your setup). The `tilt_callback` function is called whenever the tilt sensor is triggered. Inside this function, you can add the necessary actions for the capping machine when a bottle is tilted.

The `GPIO.add_event_detect` method is used to detect rising edge events (when the tilt sensor is triggered) and call the `tilt_callback` function. The `bouncetime` parameter is set to 300 milliseconds to avoid false triggers caused by noise or bouncing of the sensor.

The code runs an infinite loop to keep the program running until the user interrupts it by pressing Ctrl+C. Upon interruption, the GPIO pins are cleaned up to ensure proper termination of the program.

Note: This code assumes you are using a Raspberry Pi with the RPi.GPIO library. Automatic Packing Line

#Automatic #Plastic #Bottle #Capping #Machine