Title: Enhancing Efficiency in the Automotive Industry with Automatic Handling Machines and Semi-Automated Material Handling Systems

Description:

Introduction:

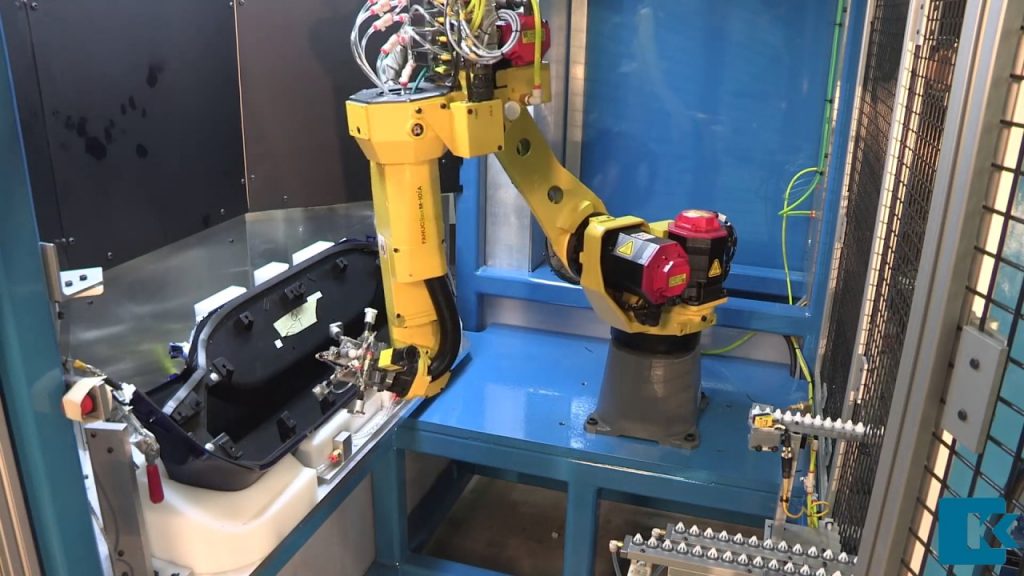

Welcome to our informative video on Automatic Handling Machines, Semi-Automated Material Handling Systems, and the extensive range of solutions offered by Koops for the automotive industry. If you are seeking to enhance the efficiency and productivity of your facility through automation, this video is a must-watch!

Video Content:

In this video, we delve into the world of Automatic Handling Machines and Semi-Automated Material Handling Systems, exploring their immense potential in revolutionizing the automotive industry. We highlight the key benefits, operation steps, and interesting facts about these advanced systems.

Key Takeaways:

- Discover how Automatic Handling Machines can streamline material handling processes, minimizing human intervention, and reducing the risk of errors.

- Gain insights into the capabilities of Semi-Automated Material Handling Systems, which combine human expertise with automated features for optimized efficiency.

- Learn about Koops' expertise in designing and building customized automation solutions tailored to the specific needs of automotive manufacturers.

- Explore the vast range of applications where these innovative systems can be implemented, such as assembly lines, packaging, sorting, and more.

- Understand how automation can boost productivity, reduce costs, and enhance overall operational efficiency in the automotive industry.

Call to Action:

If you're ready to take your automotive facility to the next level of automation, contact us today to discuss how Koops can design and build a tailor-made solution for your specific requirements. Don't forget to hit the like button, subscribe to our channel for more informative videos, and share this video with fellow industry professionals to spread awareness about the benefits of Automatic Handling Machines and Semi-Automated Material Handling Systems.

Additional Tags and Keywords:

Automatic Handling Machines, Semi-Automated Material Handling Systems, Koops, automotive industry, automation solutions, efficiency, productivity, assembly lines, packaging, sorting, customized automation, operational efficiency, automotive manufacturers, material handling processes, benefits of automation.

Hashtags:

#AutomaticHandlingMachines #SemiAutomatedMaterialHandling #KoopsAutomation #EfficiencyInAutomotiveIndustry #CustomizedAutomation #OperationalEfficiency #AutomotiveManufacturers #MaterialHandlingSolutions

A tilter for a Semi-Automated Material Handling System is a device that is used to tilt or rotate objects or materials for better positioning or easier handling. Here is a basic outline for a tilter program:

1. Initialize the tilter system, including setting up the required sensors and actuators.

2. Start the tilter program loop.

3. Read input from the user or the automated system to determine the desired tilt angle or rotation.

4. Activate the necessary actuators to tilt or rotate the object.

5. Use sensors or feedback mechanisms to monitor the tilt angle or rotation and ensure it reaches the desired position.

6. If the desired position is reached, stop the actuators and move to the next step. If not, continue adjusting until the desired position is achieved.

7. Once the desired tilt angle or rotation is achieved, pause the tilter program loop and wait for further instructions.

8. If a new tilt angle or rotation is requested, go back to step 3.

9. If no further instructions are received, the tilter program can either wait in a standby mode or be terminated.

The above is a general outline, and the actual implementation may vary based on the specific requirements and components of the Semi-Automated Material Handling System. It's important to consider safety protocols and error handling mechanisms to ensure the tilter operates smoothly and efficiently.Handling Machine

#SemiAutomated #Material #Handling #System