Title: Efficient Packaging Line Automation for Custard Packing - Ultimate Solutions for Filling, Sealing, and Versatile Container Closing

Description:

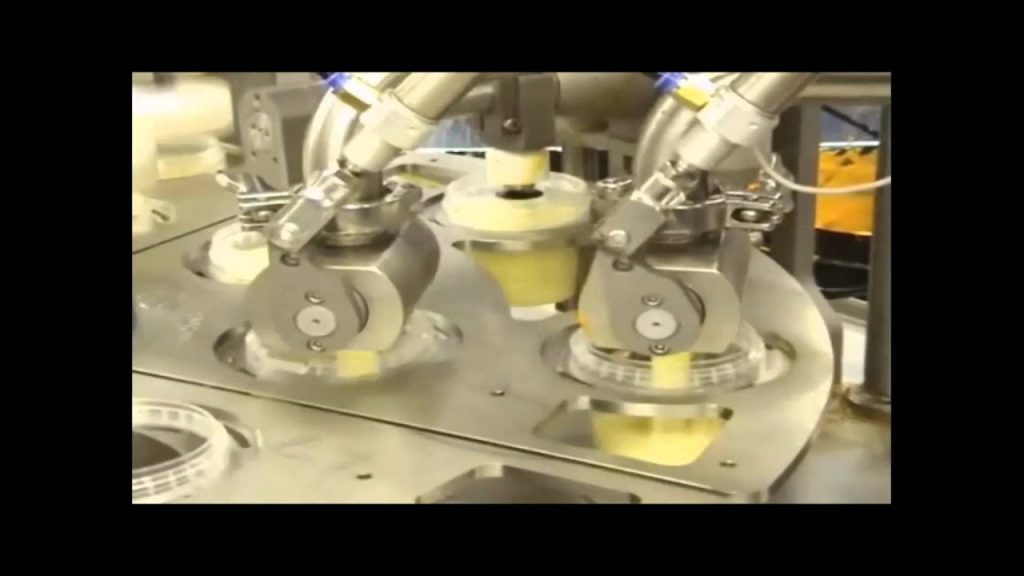

Welcome to our informative video on Packaging Line Automation and the revolutionary Starwheel Pot Filling and Sealing Machine. This highly flexible and performance-driven rotary container sealing and closing Starwheel machine offers unlimited versatility, making it the ultimate solution for efficient custard packing.

Introduction:

In this video, we explore the cutting-edge technology behind Packaging Line Automation, focusing on the game-changing Starwheel Pot Filling and Sealing Machine. Discover how this innovative solution revolutionizes the custard packing process, streamlining operations and enhancing productivity.

Video Content:

1. Key Points:

- Unveiling the Packaging Automation Starwheel Pot Filling and Sealing Machine: Explore the advanced features and functionalities that make this machine a game-changer in the industry.

- Superior Performance and Endless Versatility: Learn how this highly flexible rotary container sealing and closing Starwheel machine can adapt to various packaging requirements, optimizing production efficiency.

- Seamless Operation Steps: Discover the step-by-step process of using the machine, ensuring smooth and error-free packaging operations.

- Enhanced Product Safety and Shelf Life: Understand how the machine's sealing capabilities ensure the freshness and integrity of custard products, extending their shelf life.

2. Key Highlights:

- Customized Packaging Solutions: Experience the flexibility of the Starwheel Pot Filling and Sealing Machine, as it caters to different container sizes, shapes, and sealing requirements.

- High-Speed Performance: Witness the machine's remarkable speed and accuracy, significantly reducing production time and increasing output.

- Intelligent Control System: Learn about the advanced control features that enable precise adjustments, ensuring consistent packaging quality.

- Hygienic Design and Easy Maintenance: Discover the machine's sanitary design, facilitating effortless cleaning and maintenance for optimal operational efficiency.

Call to Action:

If you found this video informative, please consider liking, subscribing, and sharing it with others in the industry. Stay tuned for more exciting updates on packaging automation solutions.

Additional Tags and Keywords:

Packaging Line Automation, Custard Packing Line, Starwheel Pot Filling and Sealing Machine, Rotary Container Sealing, Container Closing, Efficient Packaging Solutions, Versatile Packaging Automation, Enhanced Productivity, Sealing Technology, Packaging Efficiency.

Hashtags:

#PackagingLineAutomation #CustardPacking #StarwheelMachine #ContainerSealing #EfficientPackaging #VersatileAutomation #ProductivityEnhancement

Here is a sample tilter for the Custard Packing Line's Packaging Automation Starwheel Pot Filling and Sealing Machine:

Title: Custard Packing Line Tilter - Packaging Automation Starwheel Pot Filling and Sealing Machine

Objective:

The objective of this tilter is to ensure the smooth operation of the Custard Packing Line's Packaging Automation Starwheel Pot Filling and Sealing Machine by minimizing errors and improving efficiency during the filling and sealing process.

Procedure:

1. Pre-Setup:

a. Ensure that the tilter is properly calibrated and functioning correctly.

b. Verify that the Packaging Automation Starwheel Pot Filling and Sealing Machine is clean and in good working condition.

2. Start-up:

a. Power on the tilter and the Packaging Automation Starwheel Pot Filling and Sealing Machine.

b. Allow sufficient time for the machines to warm up and reach the desired operating temperature.

3. Pot Filling:

a. Position the empty pots precisely on the tilter's input conveyor.

b. Activate the tilter to transfer the pots onto the Packaging Automation Starwheel Pot Filling and Sealing Machine's input conveyor.

c. Ensure that the pots are properly aligned and securely placed on the input conveyor to avoid jams or misalignments.

4. Filling Process:

a. Monitor the filling process to ensure accurate and consistent filling levels.

b. Adjust the tilter's speed and angle if necessary to maintain proper pot positioning and prevent spills or overfilling.

c. Regularly inspect the filling nozzles and clear any blockages or obstructions that may affect the filling process.

5. Sealing Operation:

a. Once the pots are filled, activate the tilter to transfer the filled pots onto the Packaging Automation Starwheel Pot Filling and Sealing Machine's sealing station.

b. Ensure that the pots are securely positioned on the sealing station to prevent any leakage or deformation during the sealing process.

c. Monitor the sealing operation to detect any abnormalities or malfunctions. Immediately address any issues to prevent packaging errors or damage.

6. Post-Process:

a. After sealing, activate the tilter to transfer the sealed pots onto the output conveyor or packaging line.

b. Inspect the sealed pots for any defects or irregularities.

c. Remove any damaged or faulty pots from the packaging line to maintain product quality.

7. Shutdown:

a. Power off the tilter and Packaging Automation Starwheel Pot Filling and Sealing Machine.

b. Clean and sanitize the machines according to the manufacturer's guidelines.

c. Perform regular maintenance and inspections on the tilter to ensure its continuous functionality.

Note: This is a general tilter procedure and may require adjustments based on the specific model and specifications of the Packaging Automation Starwheel Pot Filling and Sealing Machine used in the Custard Packing Line. Always refer to the manufacturer's instructions for proper operation and safety guidelines. Automatic Packing Line

#Custard #Packing #Line #Packaging #Automation #Starwheel #Pot #Filling #Sealing #Machine