If you're in the market for a Pallet Stretch Wrap Machine, then you've come to the right place. In this article, we will explore the benefits and functionality of this essential packaging equipment. Whether you're a small business owner or part of a large manufacturing operation, a Pallet Stretch Wrap Machine can greatly improve your packaging process and efficiency.

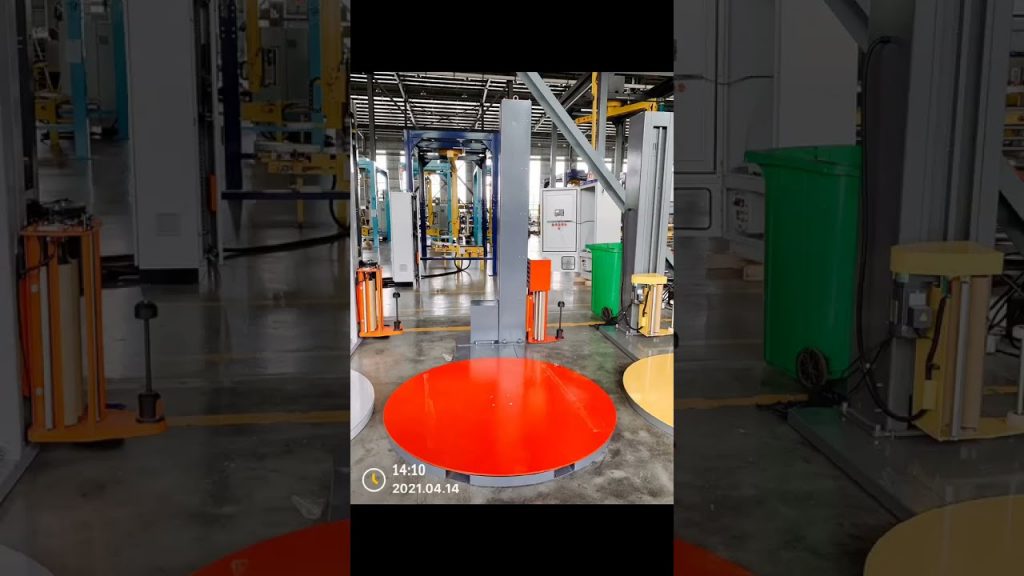

The Pallet Stretch Wrap Machine is a revolutionary piece of equipment that automates the process of wrapping pallets with stretch film. This machine is designed to securely wrap and protect your products during transportation and storage. It eliminates the need for manual wrapping, which can be time-consuming and inefficient.

One of the key benefits of using a Pallet Stretch Wrap Machine is its ability to provide a tight and secure wrap around your pallets. This ensures that your products are well-protected and less susceptible to damage. The machine applies the stretch film evenly and consistently, resulting in a professional and neat appearance.

Another advantage of using a Pallet Stretch Wrap Machine is the significant reduction in labor costs. With the machine doing the majority of the work, your employees can focus on other important tasks, increasing productivity and efficiency in your operation. Additionally, the machine can handle large volumes of pallets, saving you valuable time and effort.

The Pallet Stretch Wrap Machine is also highly versatile, accommodating a wide range of pallet sizes and shapes. It can wrap both standard and irregular-shaped pallets, ensuring that your products are properly secured regardless of their dimensions. This versatility makes it an ideal choice for businesses in various industries.

In terms of operation, the Pallet Stretch Wrap Machine is user-friendly and easy to operate. It typically features a user-friendly control panel that allows you to adjust settings such as wrap tension, film speed, and number of wraps. Some models even have pre-programmed settings for different types of products, further simplifying the process.

When it comes to maintenance, the Pallet Stretch Wrap Machine requires minimal upkeep. Regular cleaning and inspection of the machine's components are usually sufficient to keep it running smoothly. Additionally, most machines are built to withstand the demands of a busy warehouse environment, ensuring durability and longevity.

If you're considering investing in a Pallet Stretch Wrap Machine, it's important to choose a reliable and reputable manufacturer. Look for a company that specializes in packaging equipment and has a proven track record in the industry. They should offer a range of machine options to suit your specific needs and provide excellent customer support.

In conclusion, a Pallet Stretch Wrap Machine is an invaluable tool for any business that deals with palletized products. Its ability to securely wrap and protect pallets can greatly enhance your packaging process, saving you time and money. So why wait? Check out leading manufacturers for the professional solution today!

Check the coil packing solution with a leading manufacturer for the professional solution just here. Pallet Wrapping Machine

"Maximizing Efficiency: A Guide to Pallet Stretch Wrapping with Rotary Stretch Wrapping Machines and Stretch Wrap Machines"