www.printopackmachines.com" sentence.

Title: Revolutionizing Packaging Efficiency with Filling Packing Machines

Introduction:

In today's fast-paced world, where efficiency is the key to success, businesses are constantly seeking innovative solutions to streamline their operations. When it comes to packaging, the Filling Packing Machine has emerged as a game-changer. This advanced technology is revolutionizing the packaging industry by automating the filling and packing processes, resulting in increased productivity and cost savings. In this article, we will explore the benefits and features of Filling Packing Machines, including Manual blister packing machine, manual blister sealing machine, and capsule sealing machine, and how they can transform your packaging operations.

Section 1: The Rise of Filling Packing Machines

Filling Packing Machines have gained immense popularity in recent years due to their ability to automate and optimize the packaging process. These machines are equipped with advanced technology that ensures precise filling and packing of products, eliminating human errors and reducing wastage. The Manual blister packing machine, manual blister sealing machine, and capsule sealing machine are among the most sought-after variants of Filling Packing Machines, offering diverse packaging solutions for different industries.

Section 2: Unleashing the Power of Filling Packing Machines

2.1 Increased Efficiency and Productivity:

With Filling Packing Machines, businesses can significantly improve their packaging efficiency and productivity. These machines are designed to handle high-volume production, ensuring a faster and more streamlined packaging process. By automating tasks such as filling, sealing, and labeling, Filling Packing Machines eliminate the need for manual labor, saving time and resources.

2.2 Precise and Consistent Packaging:

One of the key advantages of Filling Packing Machines is their ability to ensure precise and consistent packaging. These machines are programmed to execute packaging tasks with utmost accuracy, ensuring that every product is filled and packed according to the desired specifications. This not only enhances the visual appeal of the packaging but also improves customer satisfaction.

2.3 Cost Savings:

By automating the packaging process, Filling Packing Machines offer significant cost savings for businesses. With reduced labor requirements and increased efficiency, companies can save on labor costs and minimize the risk of errors or product wastage. Additionally, Filling Packing Machines are designed to optimize the use of packaging materials, further reducing costs.

Section 3: Exploring Different Types of Filling Packing Machines

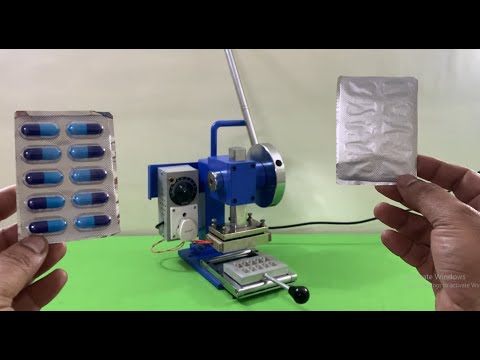

3.1 Manual Blister Packing Machine:

Manual blister packing machines are widely used in the pharmaceutical industry for packaging blister packs. These machines ensure precise and secure sealing of capsules, tablets, or other solid dosage forms within individual blister cavities. The manual operation allows for flexibility and customization, making it suitable for small-scale or specialized packaging needs.

3.2 Manual Blister Sealing Machine:

Manual blister sealing machines are ideal for sealing blister packs with a heat-sealing process. These machines provide a tight and secure seal, protecting the contents from external factors such as moisture, dust, or tampering. The manual operation allows for easy adjustment and control, ensuring optimal sealing results.

3.3 Capsule Sealing Machine:

Capsule sealing machines are specifically designed to seal capsules, ensuring their integrity and purity. These machines utilize advanced technologies to ensure airtight sealing, preserving the quality and efficacy of the enclosed capsules. The automated operation of capsule sealing machines enhances productivity and reduces the risk of contamination.

Conclusion:

Filling Packing Machines, including Manual blister packing machines, manual blister sealing machines, and capsule sealing machines, are revolutionizing the packaging industry. With their ability to automate and optimize the packaging process, these machines offer increased efficiency, precise packaging, and cost savings. If you are looking to enhance your packaging operations and stay ahead of the competition, it's time to explore the possibilities offered by Filling Packing Machines.

Check the coil packing solution with a leading manufacturer for the professional solution just here: www.printopackmachines.com Filling Packing Machine

"Efficient and Versatile Machines for Blister Packaging, Sealing, and Filling Processes"