Title: High-Speed Packing Line | High-Speed Automatic Filling Packing Machine for Various Sugar Bag Sizes

Description:

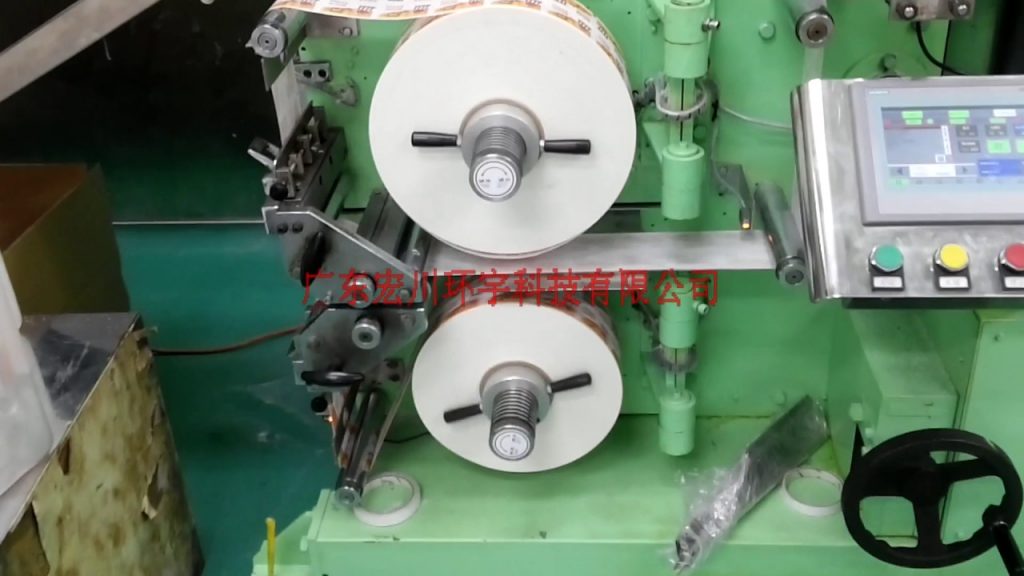

Welcome to our high-speed packing line video, showcasing our advanced automatic filling packing machine designed for efficiently packaging sugar in 1g, 5g, 10g, 25g, and 50g bags or sachets. This innovative machine ensures precise and fast packaging, optimizing production processes and enhancing productivity in sugar manufacturing.

Introduction:

In this video, we present our state-of-the-art high-speed packing line, which incorporates a high-speed automatic filling packing machine specifically designed for packaging sugar in various bag sizes. We aim to provide a comprehensive overview of the machine's features, operation steps, and benefits.

Video Content:

Our high-speed packing line offers numerous advantages for sugar manufacturers. With its advanced technology and automation capabilities, it streamlines the packaging process, ensuring accuracy, efficiency, and high production output.

Key Features:

1. Precision Packaging: Our machine enables precise filling of sugar in 1g, 5g, 10g, 25g, and 50g bags, ensuring consistent weight distribution.

2. High-Speed Performance: The automatic filling process enables fast packaging, significantly increasing production efficiency.

3. Versatile Bag Sizes: Our machine offers flexibility by accommodating various sugar bag sizes, catering to diverse customer requirements.

4. Easy Operation: The user-friendly interface and intuitive controls make operating the machine simple and hassle-free.

5. Reliable and Durable: The high-quality construction and robust design ensure long-lasting performance and minimal downtime.

Operation Steps:

1. Bag Loading: The bags or sachets are loaded onto the machine, ready for filling.

2. Sugar Filling: The machine precisely measures and fills the bags with the desired amount of sugar, ensuring accurate weight distribution.

3. Sealing: Once filled, the bags are sealed securely to maintain product freshness and prevent spillage.

4. Bag Discharge: The filled and sealed bags are discharged from the machine for further processing or packaging.

Call to Action:

If you are a sugar manufacturer looking to enhance your production efficiency, our high-speed packing line with its advanced automatic filling packing machine is the ideal solution. Don't miss out on the opportunity to optimize your packaging processes and boost productivity. Like, subscribe, and share this video to stay updated with the latest advancements in the sugar industry.

Additional Tags and Keywords: high-speed packing line, automatic filling packing machine, sugar bag packaging, sugar sachet packaging, sugar manufacturing, production efficiency, packaging technology, advanced automation.

Hashtags: #highspeedpackingline #automaticfillingmachine #sugarbagpackaging #sugarsachetpackaging #packagingtechnology #sugarmanufacturing #productionefficiency

Title: High-Speed Automatic Filling and Packing Machine for Various Sugar Bag Sizes

Introduction:

The high-speed automatic filling and packing machine is designed to cater to the efficient packaging needs of sugar in different quantities, ranging from 1g to 50g. This versatile machine ensures accurate and rapid filling of sugar into bags or sachets, revolutionizing the packaging process for sugar manufacturers.

Features and Benefits:

1. High-Speed Filling: The machine is equipped with cutting-edge technology that enables it to achieve high-speed filling without compromising accuracy. It optimizes production capacity, ensuring a smooth and efficient packaging process.

2. Multiple Bag Sizes: The machine is capable of filling and packing sugar into bags of various sizes, including 1g, 5g, 10g, 25g, and 50g. This flexibility allows manufacturers to cater to different customer demands and market requirements.

3. Precise Weighing System: The tilter is equipped with a precise weighing system that ensures accurate measurements for each bag. This eliminates any inconsistencies in sugar quantity, leading to customer satisfaction and enhanced product quality.

4. User-Friendly Interface: The machine features a user-friendly interface that simplifies operation and minimizes the learning curve. Operators can easily adjust settings, monitor the production process, and troubleshoot any issues that may arise.

5. Durable and Hygienic Construction: The tilter is constructed with high-quality materials, ensuring durability and longevity. Its design also meets strict hygiene standards, making it suitable for use in food processing environments.

6. Automated Packaging Process: The machine automates the entire packaging process, reducing labor costs and increasing overall productivity. It can continuously fill and pack sugar bags without interruptions, resulting in a streamlined production line.

7. Customizable Options: Manufacturers have the option to customize the machine according to their specific requirements. This includes adjusting filling speed, bag sizes, and incorporating additional features to meet unique demands.

Conclusion:

The high-speed automatic filling and packing machine for various sugar bag sizes is a game-changer for sugar manufacturers. Its ability to accurately fill and package sugar in quantities ranging from 1g to 50g ensures product consistency and customer satisfaction. With its advanced features, durability, and automation capabilities, this machine significantly enhances production efficiency, allowing manufacturers to meet market demands effectively. Automatic Packing Line

#High #speed #automatic #filling #packing #machine #10g #25g #50g #sugar #bagsugar #sachet