Title: Bag Handling Machine - A Comprehensive Solution for Efficient and Precise Bag Handling | BluePrint Automation (BPA)

Description:

Introduction:

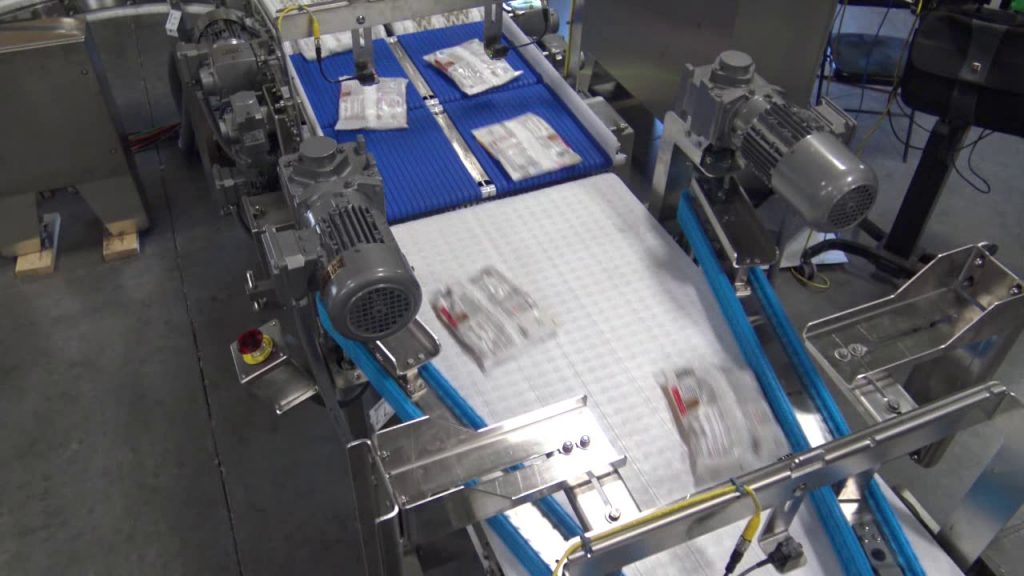

Welcome to our video showcasing the remarkable Bag Handling Machine by BluePrint Automation (BPA). This cutting-edge technology revolutionizes bag handling processes, delivering unparalleled efficiency and precision. In this video, we will explore the various features and capabilities of the Bag Handling Machine, including flipping, high-speed merge, product settling, and turning, which make it a game-changer in the industry.

Video Content:

In this video, we will delve into the Bag Handling Machine's outstanding functionalities, highlighting its ability to streamline bag handling operations and optimize productivity. With its advanced flipping mechanism, the machine ensures bags are positioned correctly, minimizing errors and maximizing efficiency.

The high-speed merge feature allows for the seamless merging of multiple bag lines, eliminating bottlenecks and ensuring a smooth flow of production. By employing innovative product settling techniques, the Bag Handling Machine guarantees the precise alignment and orientation of bags, enhancing overall product quality.

Moreover, with its exceptional turning capabilities, the machine enables bags to be efficiently rotated in the desired direction, facilitating a seamless transition between different stages of bag handling. These features collectively enable businesses to optimize their bag handling processes, saving time, reducing labor costs, and minimizing errors.

Call to Action:

If you found this video informative and want to stay updated with the latest advancements in bag handling technology, don't forget to like, subscribe, and share our channel. By doing so, you'll be joining a community of industry professionals and enthusiasts who are passionate about efficient bag handling solutions.

Additional Tags and Keywords:

Bag Handling Machine, BluePrint Automation, BPA, bag handling project, flipping bags, high-speed merge, product settling, turning bags, bag handling technology, bag handling efficiency, bag handling automation, bag handling solutions, bag handling industry, bag handling processes

Hashtags:

#BagHandlingMachine #BluePrintAutomation #EfficientBagHandling #AutomationTechnology #ProductivityOptimization #BagHandlingSolutions

A tilter for 55979 BluePrint Automation (BPA) Bag Handling system can be designed as follows:

1. Design a sturdy framework: Create a strong and durable framework using steel or aluminum to support the bag handling system and ensure stability during tilting operations.

2. Install a motorized tilting mechanism: Incorporate a motorized tilting mechanism that can be controlled remotely or through a control panel. This mechanism should be able to tilt the bag handling system at different angles as required.

3. Implement safety features: Integrate safety features such as emergency stop buttons, limit switches, and sensors to ensure the operator's safety and prevent any accidents during the tilting process.

4. Develop a conveyor system: Design a conveyor system that can transport bags onto the tilter and safely offload them after tilting. This conveyor should be synchronized with the tilting mechanism to ensure smooth material flow.

5. Include adjustable guides: Incorporate adjustable guides or clamps to secure the bags in place during tilting. These guides should be adjustable to accommodate bags of different sizes and prevent them from slipping or falling during the tilting process.

6. Programmable controls: Develop a user-friendly control system that allows the operator to program specific tilting angles and speeds. This control system should also have features like auto-reverse, where the tilter will automatically return to its original position after completing a tilt.

7. Test and fine-tune: Conduct thorough testing of the tilter to ensure its reliability, efficiency, and safety. Make necessary adjustments and fine-tune the system based on the test results.

8. Provide maintenance and support: Create a maintenance schedule and provide guidelines for regular maintenance to ensure the tilter's longevity. Also, offer technical support to address any issues or concerns that may arise during the tilter's operation.

By following these steps, a tilter for the 55979 BluePrint Automation (BPA) Bag Handling system can be developed to efficiently and safely handle bags during the tilting process.Handling Machine

#BluePrint #Automation #BPA #Bag #Handling